Metal Craft Manufacturing for Garden Solar Lights

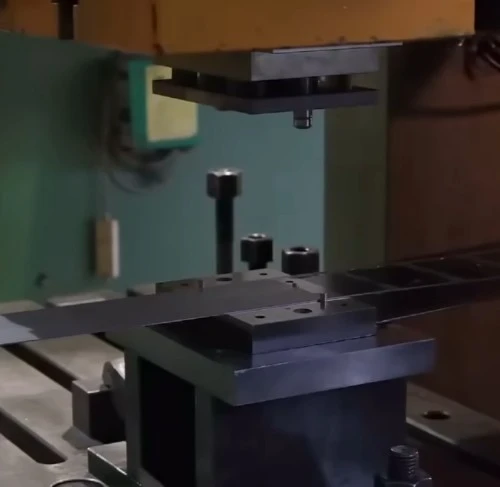

Our metal workshop handles full-process fabrication including cutting, bending, welding, stamping and CNC detailing. By controlling every step in-house, we ensure structural strength, consistent dimensions, and stable quality across all iron solar lanterns, stakes, and decorative silhouettes. This is the foundation that allows us to build durable, weather-resistant outdoor lighting for global retailers.

- Design translation: Turn brand sketches into clean, manufacturable metal patterns and 3D forms.

- Metal craftsmanship: Use CNC stamping, laser cutting and welding to keep details sharp and structures stable.

- Outdoor reliability: Match metal thickness and coatings so lights stay solid and rust‑resistant outdoors.

More Metal

Light Covers collection:

Metal (Iron Craft) Options for Outdoor Garden Light Housings

Durable, Decorative, and Crafted for Outdoor Performance

Metal is one of the most versatile and expressive materials in garden lighting. At GlowYard, we use a wide range of iron-craft techniques to shape light, enhance durability, and create distinctive visual styles for global outdoor lighting brands.

Below are the 9 main metal expressions commonly used in solar and wired garden lights.

Perforated Metal Patterns

Uniform round, square, or custom holes punched with stamping dies.

Benefits

-

Lower cost than laser cutting

-

Smooth, diffused lighting patterns

Common Uses

Column lights, outdoor post lamps, decorative shades.

Decorative Sculpted Metal (Flowers, Animals, Shapes)

Custom iron-craft designs such as flowers, leaves, animals or thematic patterns.

Benefits

-

Highly unique and artistic

-

Strong visual impact for garden décor

-

One of GlowYard’s signature capabilities

Common Uses

Animal solar lights, floral lamps, themed collections.

Laser-Cut Metal Shades

Intricate patterns created with high-precision laser cutting.

Benefits

-

Highly decorative patterns

-

Strong light-and-shadow effect for ambience

Common Uses

Garden lanterns, hanging lights, table lamps, decorative solar lights.

Wireframe / Mesh Shades

Metal wires bent and welded into cage or mesh structures.

Benefits

-

Lightweight and strong

-

Modern, industrial or Nordic style

Common Uses

Cage wall lamps, minimalistic hanging lights, outdoor table lights.

Stamped Metal Housing

Metal sheets pressed into shape with precision molds.

Benefits

-

Cost-effective for mass production

-

Stable structure and consistent dimensions

Common Uses

Pillar lights, wall lights, lantern housings, roof caps.

Cast Metal Housings

Iron or aluminum cast into thick, solid shapes.

Benefits

-

Excellent outdoor durability

-

Premium look with strong structural integrity

Common Uses

High-end garden lights, pillar lights, European-style outdoor lamps.

Rolled Metal Sheet Shades

Flat metal sheets rolled and welded into cylinders, cones, or geometric forms.

Benefits

-

Stable form and clean lines

-

Ideal for modern or minimalist designs

Common Uses

Pillar lights, hanging lights, pathway lights.

Hammered Metal Finish

Hand-hammered or mold-pressed texture for handcrafted surfaces.

Benefits

-

Rich reflective texture

-

Artisan-style appearance

Common Uses

Vintage-style garden lanterns, premium décor lights.

Metal Frame with Glass Panels

Iron frame combined with clear, frosted or patterned glass inserts.

Benefits

-

Classic and timeless look

-

Ideal for architectural garden lights

Common Uses

Wall sconces, post lights, vintage-style solar lanterns.

General Metal Fabrication Workflow

See how Glowyard transforms raw metal into outdoor‑ready lighting structures through a standardized multi‑step workflow—from material selection and stamping to welding, finishing and in‑process quality control.

Raw Material Selection & Blanking

-Perform shearing, laser cutting or CNC punching according to flat patterns and nesting layouts, controlling dimensional tolerances.

Stamping & Forming

-Apply rolling, deep drawing or edge rolling for curved or cylindrical parts when required.

Assembly & Welding

-Join parts by spot welding, full welding or brazing, ensuring structural strength and load safety.

-Use screws, rivets or clips instead of welding where disassembly or maintenance is required.

Grinding, Finishing & Deburring

-Remove burrs and sharp edges to avoid user injury and improve tactile feel.

-Straighten deformed parts to meet requirements for verticality, flatness and key mounting dimensions.

Surface Pre‑Treatment

Apply phosphating, passivation or similar chemical treatments to improve coating adhesion and corrosion resistance.

Re‑inspect critical visible surfaces to avoid passing deep scratches, dents or serious defects into the coating process.

CNC Cutting & Forging Capability

Precision Metal Cutting & Forging for High-Volume and Custom Outdoor Lighting

Our metal workshop is equipped to handle both custom garden light housings and large-scale OEM production. From intricate iron art patterns to high-strength structural components, we ensure every piece meets strict durability and outdoor performance standards.

polishing grinding and dust removal all in one machine

metal bending machine

CNC Laser Cutting System

400 ton single action stamping hydraulic press

metal pipe cutting machine

Metal Fabrication Capabilities

Key process highlights that support stable, repeatable metal solar light production.

Metal Raw Material Selection

- Cold‑rolled steel / iron for decorative garden structures

- Thickness options from 0.5–1.0 mm according to strength and cost

- Anti‑rust primer and coating system planned from the beginning

Forming Processes

- CNC stamping for stable dimensions and efficient mass production

- Laser cutting for precise patterns, logos and small details

- Bending and forming to create brackets, frames and 3D shapes

Welding Capabilities

- Spot welding for fast, consistent joints on thin metal parts

- Full welding for complex 3D structures and high‑stress positions

- Proven capability for animal, floral and other 3D decorative patterns

Surface Preparation (Degreasing & Grinding)

- Degreasing and cleaning before coating to improve adhesion

- Grinding, deburring and edge treatment to remove sharp burrs and weld marks

Related metal iron Outdoor Lights

Explore representative metal‑based outdoor and solar lighting designs—such as garden stakes, hanging lanterns and wall lights—that are manufactured using the same metal fabrication and finishing capabilities.

Industry Pain Points

in Metal Solar Light Manufacturing

What B2B buyers commonly encounter when sourcing metal solar lights from China.

Rust and coating failure in real outdoor use

Many factories use low‑grade steel or skip proper pre‑treatment before powder coating. After one rainy or coastal season, posts and housings start to rust, paint bubbles or peels, and complaints quickly follow.

Color and finish inconsistency between batches

Different powder suppliers, uncontrolled baking curves or manual mixing create visible color shift and gloss differences between shipments, which is fatal for retail displays and project replacements.

Thin material and weak structure to “save cost”

To win quotes, some suppliers quietly reduce metal thickness or simplify welding. Products look fine in photos, but arrive bent, wobble after installation or crack at welds under wind load.

Water ingress through joints and hardware

Poor gasket design, loose fasteners and sharp punching edges can break sealing. Rust then starts from inside, and customer only sees failures months after installation.

To understand how these issues appear across the whole production chain, you can review our outdoor lighting manufacturing overview.

How Glowyard Solves These Problems for Metal Lights

How our metal‑processing system is designed to prevent rust, deformation and inconsistency.

Material selection matched to environment

We use suitable substrates (e.g., galvanized steel, aluminum, stainless steel) based on whether the project is inland garden, coastal, or commercial. Thickness, grade and anti‑rust requirements are confirmed in the spec sheet before mass production.

Controlled surface preparation and powder coating

Metal parts go through cleaning and pre‑treatment before entering automated powder coating lines. Baking temperature and time are monitored to keep adhesion and color stable across batches.

Process control for welding and assembly

Standardized welding procedures, jigs and fixtures ensure consistent joints and angles, while deburring and smoothing steps avoid sharp edges and future coating cracks.

Integrated design of housing + electronics + sealing

Our R&D and manufacturing teams co‑design bracket points, cable routing and gasket positions so that IP and corrosion resistance are considered from the drawing stage, not patched later.

Quality Assurance for

Metal Solar Light Projects

How we test and document metal housings so they survive real outdoor conditions.

4‑stage QC system focused on metal risks

Lab tests for corrosion, adhesion and durability

IP and mechanical validation

Traceability, warranty and corrective action

Certified for Global Markets

Our factory holds BSCI, ISO 9001, and Sedex audits, and our products comply with CE, RoHS, FCC, UL, UKCA and more.

Purchasing Tips for Importers & Brand Owners of Metal Lights

Practical guidelines to write better RFQs and avoid hidden risks in metal light projects.

Specify substrate, thickness and anti‑rust level clearly

In your RFQ, define whether you need galvanized steel, aluminum or stainless, the minimum thickness, and expected outdoor lifetime (e.g., 48/96‑hour salt‑spray, coastal vs inland).

Lock color, gloss and texture with a master sample

Approve a powder‑coat chip and a finished metal part as “golden sample” with agreed RAL (or near‑equivalent), gloss level and texture. Require any formula change to be re‑approved.

Align structure and packaging with logistics reality

Metal solar lights are heavier and more rigid than plastic or resin. Confirm carton drop‑test requirements, pallet stacking limits and how sets are packed to avoid transport damage and extra freight costs.

Match customization depth with MOQ and timeline

New molds, special coatings or complex welding structures require larger MOQ and longer lead time. Reserve these for core SKUs, and use simpler modifications for test orders or seasonal runs.

For more practical details on MOQ, lead times and ordering flow, refer to our purchasing guide for solar garden lights.

Knowledge for Metal Outdoor Lighting Manufacturing

Practical guides, FAQs and insights on metal selection, anti‑corrosion treatment, outdoor durability and production best practices to help buyers design and source better metal outdoor lighting products.

Metal Solar Lights Complete Buyer’s Guide

Metal solar lights are a smart choice when you want outdoor fixtures that feel solid, durable and premium. Compared with plastic or resin housings, metal gives you better strength, a more high-end look and, when done correctly, longer service life in harsh weather.

This guide walks you through the key questions to clarify before you buy or customise metal solar lights for your brand. It is written for importers, wholesalers, retailers and brand owners who need reliable outdoor metal fixtures rather than one‑season consumer products.

Understanding Your Application and Environment

How should you define outdoor scenarios and end users for metal solar lights?

Before you choose any metal structure, start with the real‑world scenario:

- Are the lights for private gardens, hotel landscapes, memorial parks, cemeteries, public walkways or commercial facades?

- Will they be decorative accent lights, pathway markers, memorial lanterns, safety markers, or a mix of all of these?

- Are they mainly viewed from close range (for example on a table or grave) or from a distance (for example along a road or fence)?

Each scenario leads to different priorities:

- Private gardens often tolerate more delicate patterns and lighter metal.

- Public parks and cemeteries usually need stronger housings and better anti‑vandal design.

- Hotel or resort projects care more about consistency of finish and long‑term colour stability.

If you are still mapping your use cases, it is helpful to review typical installations and case studies similar to yours. For example, our application overview page at Application scenarios groups outdoor solar light use cases by scene and helps you narrow down the right product types.

How do climate, weather and corrosion risks affect your metal solar lights?

Metal performs very differently in different climates. A design that works well in a dry inland city can fail quickly in coastal or tropical regions if the material and coating system are not chosen correctly.

Key questions to clarify with your supplier:

- Are your main markets coastal, high‑humidity, heavy‑rainfall, snowy, or desert areas?

- How strong is UV exposure, and what is the typical annual temperature range?

- Will the metal parts be exposed to lawn sprinklers, standing water, salt spray or de‑icing salts?

For coastal, high‑humidity or high‑pollution areas, you may need:

- Better base material (for example galvanised steel or aluminium instead of plain mild steel).

- Multi‑layer coating systems and stricter salt spray test requirements.

- Additional sealing at joints to prevent water from sitting around metal edges.

Discuss these environmental factors upfront so the supplier can match material grade, coating system and IP rating to your actual conditions, instead of only designing for laboratory standards.

What safety, regulation and public‑space requirements apply to metal solar lights?

If your metal solar lights are installed in public spaces, safety and compliance become critical:

- Are there any local or project‑specific rules about sharp edges, exposed fasteners or load‑bearing structures?

- Do the fixtures need to resist specific impact levels (for example pedestrians, bicycles or trolleys)?

- Is there a requirement for accessible design, such as avoiding snagging points on handrails or pathways?

You should also confirm which certifications are required in your target markets (for example CE, RoHS, FCC, UKCA) and whether your supplier already holds them. A dedicated page like our product certifications typically lists available test reports and standards; this can save time in early project discussions.

Choosing the Right Metal and Structural Design

Which metals are best for solar light housings and how do they compare?

Outdoor solar lights can be made from several types of metal. Each option has different pros and cons in terms of cost, appearance, corrosion resistance and weight.

- Iron / mild steel

Pros: strong, easy to stamp and weld, cost‑effective for mass production.

Cons: needs good anti‑rust treatment; otherwise it can rust quickly, especially in coastal or humid climates.

Best for: decorative lanterns, pathway lights, and memorial lights where you want a classic or vintage look. - Galvanised steel

Pros: better inherent corrosion resistance than plain steel; good base for powder coating.

Cons: slightly higher cost and weight; surface may need additional preparation before coating.

Best for: tall poles, fence lights or structural parts where long‑term strength is critical. - Stainless steel (for example 304)

Pros: good corrosion resistance, clean modern appearance, suitable for premium product lines.

Cons: higher cost; can show fingerprints or scratches on polished finishes; forming and welding may be more demanding.

Best for: high‑end garden, architectural or hotel projects where durability and appearance are both high priority. - Aluminium

Pros: light weight, naturally corrosion‑resistant when properly finished; good for larger shapes where weight and shipping cost matter.

Cons: softer than steel; requires correct alloy and thickness to avoid deformation.

Best for: wall lights, fence lights, or decorative fixtures where weight reduction is important.

When you decide on a metal, also ask your supplier how it compares to other housing options you use, such as plastics, resin or glass. Many buyers use metal for structural or premium SKUs and other materials for decorative series, and learn about these processes through dedicated pages like plastic, resin or glass lights manufacturing guides.

How do wall thickness, profiles and structure impact metal solar light strength?

Even if you pick the right metal, the design can still fail if the structure is too thin or poorly supported:

- Very thin walls may deform during stamping, bending or welding.

- Large surfaces without ribs or folds can vibrate or dent during transport.

- Long, slender components may bend during installation or everyday use.

To avoid these issues, clarify:

- What sheet thicknesses are acceptable for your price segment and quality positioning?

- Which parts need extra reinforcement (for example additional folds, ribs, brackets or thicker material)?

- Are there parts that will be stepped on, leaned against or frequently touched by users?

Ask your supplier to comment on possible deformation risks and to suggest small design tweaks that increase rigidity without adding too much cost or weight. Good engineers will often propose alternative fold lines, gussets or joint methods to balance appearance and strength.

How should you design edge safety, assembly and maintenance for metal solar lights?

Metal edges can be dangerous if not handled correctly, especially in public or family environments. During the design phase, address the following:

- How will sharp edges be removed (for example deburring, grinding, tumbling)?

- Are there any cut‑outs or decorative patterns where users may accidentally touch an unfinished edge?

- Will screws, rivets or brackets be exposed where people may bump into them?

Assembly method also affects long‑term maintenance:

- Welded structures are strong and clean, but can be harder to repair or modify.

- Screwed or riveted structures may be slightly slower to assemble but easier to service.

- Snap‑fit or hybrid solutions can combine clean appearance with service access.

Define early which parts should be permanently fixed and which should remain accessible for battery replacement, LED module upgrades or wiring checks. This makes it easier for your supplier to design practical housings and choose appropriate fixing methods.

Anti‑Rust, Coating and Outdoor Protection

What corrosion protection system do you need for your metal solar lights?

For metal solar lights, anti‑rust performance is not just a coating choice; it is a full system that includes base material, surface preparation, coating layers and drying/curing quality.

Important questions to ask:

- Do you need a basic anti‑rust solution for mild climates or a heavy‑duty system for coastal or industrial regions?

- What salt spray test hours are required by your customers or retailers (for example 24, 48, 96 hours or more)?

- Are there specific test methods your market prefers (for example neutral salt spray vs acetic)?

A robust system might include:

- Selection of galvanised steel or aluminium for critical parts instead of plain steel.

- Chemical pre‑treatment to improve coating adhesion and corrosion resistance.

- Primer + powder coating or e‑coating + top coat to protect edges and corners.

Ask your supplier to share how they test their metal solar light housings in their internal quality processes and how those tests relate to your market expectations.

How should you choose colour, texture and finish for metal solar lights?

Metal allows a much wider range of visual effects than many other materials. You can combine classic forms with modern finishes to position your brand clearly in the market.

Common finishes include:

- Matte or satin black for a modern minimalist look.

- Antique bronze, copper or brushed effects for vintage garden or memorial themes.

- Hammered or textured surfaces that help hide minor surface imperfections and improve scratch resistance.

When discussing finishes, be as specific as possible:

- Do you have RAL, Pantone or sample references for your target colour?

- Should the overall impression be matte, semi‑gloss or high‑gloss?

- Are there areas where coating must be masked (for example threads, electrical contacts, sliding joints)?

Good suppliers will keep detailed finish records and can reproduce the same look consistently across batches. If you are planning a large or long‑term project, confirm how they manage colour consistency, including approved master samples and documented process parameters.

Which UV, salt spray and other outdoor tests should metal solar lights pass?

Outdoor metal solar lights are exposed to UV, rain, temperature changes and, in some cases, salt and chemicals. To avoid complaints after installation, clarify your test expectations early in the project:

- What IP rating is required (for example IP44 for basic outdoor use, IP65 or IP67 for harsher conditions)?

- Do you require UV ageing tests for coating and plastic components used together with metal?

- Is salt spray testing mandatory for certain projects or tenders?

Discuss which tests are already part of your supplier’s routine quality system and which would be run only for specific projects. A dedicated quality overview page, such as our quality control and testing section, typically explains these standard tests and helps you align expectations with your own QC team.

Light Effect and Solar System Integration on Metal Housings

How can metal housing design shape the lighting effect of solar lights?

One of the biggest advantages of metal housings is the ability to create strong visual patterns using cut‑outs, perforations and layered structures. Before you lock in a design, think carefully about the light effect you want:

- Do you want the light to project patterns onto the ground, walls or surrounding surfaces?

- Should the light be 360° around the fixture, or mainly directional (for example up/down on a wall or focused on a path)?

- How bright should the effect be? Is it mainly decorative mood lighting or also functional for safety?

Work with your supplier to match housing design, LED brightness and diffuser elements (for example frosted glass or acrylic) so that the final effect matches your product promises and marketing images. Request photos or short videos from different angles to verify the effect before mass production.

How does solar panel placement affect charging performance on metal solar lights?

On metal solar lights, the solar panel is usually mounted on the top or on a separate bracket. Its position and angle matter greatly for real‑world performance:

- Is the panel free from shading by the metal structure, trees, walls or other objects during most of the day?

- Is the installation angle optimised for your main markets’ latitude, or will customers adjust the angle themselves?

- Are there cable routing points where metal edges might damage the wiring if not protected?

Ask for guidance on panel size, expected charging time and typical nightly runtime in your target regions. For important projects, you may want to review real test data rather than only theoretical numbers.

How should you handle waterproofing, heat management and service access for metal solar lights?

Metal is a good conductor of heat, which is both an advantage and a design consideration:

- A properly designed metal housing can help dissipate heat from LEDs and electronics, improving lifespan.

- Poorly thought‑out designs can trap heat in enclosed spaces, especially in very hot climates.

At the same time, you must ensure adequate waterproofing:

- Clarify where gaskets, seals and waterproof joints are located.

- Check how the design prevents water from pooling around joints or fasteners.

- Confirm how the structure achieves the targeted IP rating in real installations.

Finally, consider maintenance:

- How will customers or installers access the battery compartment or electronics if replacement is required?

- Are there standard screws and tools, or proprietary fasteners?

- Is there enough cable slack and mechanical protection when opening and closing access doors?

Agreeing these details in advance reduces future service costs and improves user satisfaction.

Metal Manufacturing Process and Quality Control

For a visual overview of stamping, welding and finishing steps, you can also refer to our metal lights manufacturing guide.

How do metal solar light designs move from drawings to tooling?

A successful metal solar light starts with a clear design package. Before tooling begins, you and your supplier should align on:

- 2D drawings and 3D models, including tolerances and critical dimensions.

- Which parts are shared with other models and which are unique to this project.

- Expected annual volumes and product roadmap (for example, future size or pattern variations).

Based on this information, the factory will decide whether to use laser cutting, progressive stamping dies, bending tools or more complex forming processes. Good suppliers will explain where they are using standard tools versus dedicated tooling and how this affects cost, lead time and flexibility.

How can you control stamping, welding and finishing quality in metal solar lights?

Metal processes each come with their own quality challenges:

- Stamping and bending must be controlled to avoid burrs, distortion and misalignment.

- Welding quality affects both appearance and strength; poor welds can lead to cracks, rust spots and rejected inspections.

- Surface preparation before coating has a direct impact on adhesion, colour consistency and corrosion resistance.

During your supplier evaluation, ask questions such as:

- What equipment is used for metal fabrication and finishing, and how is it maintained?

- How are welding parameters documented and controlled?

- How does the factory ensure consistency between different shifts and batches?

This is also a good moment to request factory photos, equipment lists or manufacturing videos so you can better understand how your metal solar lights are produced from raw material to finished goods.

How should metal solar lights be inspected, IP-tested and packaged before shipment?

For outdoor metal solar lights, final inspection should cover both appearance and function:

- Visual checks for coating defects, scratches, weld marks and deformation.

- Functional checks for charging, lighting modes, sensors and timers.

- Waterproof tests to confirm the specified IP level.

Packaging is a critical but often overlooked part of quality:

- Well‑designed inner and outer cartons protect metal surfaces from rubbing, chipping and denting during transport.

- Moisture protection (for example desiccant, plastic bags) may be necessary for long sea shipments.

- Clear labelling helps your warehouse and customers handle products correctly.

Clarify whether you need standard export packaging or retail‑ready colour boxes, and whether different markets require separate artwork or languages.

Customisation, Series Planning and Cost Efficiency

How can you build a coherent series of metal solar lights?

Most successful brands do not buy a single metal solar light model; they develop a coherent series:

- A consistent design language across pathway lights, wall lights, fence lights and lanterns.

- Several size and pattern variations that share the same core metal structure.

- Optional features such as different colour temperatures, lighting modes or decorative inserts.

When you plan a series early, your supplier can design shared metal components, jigs and fixtures that lower your overall tooling and unit costs. This also makes it easier to launch new variants later without starting from zero. You can also review your existing assortment or browse our products overview to identify where a coherent metal series would strengthen your lineup.

How do you balance material grade, thickness and cost for metal solar lights?

Metal choice and wall thickness have a strong impact on both quality perception and cost:

- Thicker metal usually feels more premium and resists deformation, but increases material and shipping cost.

- Higher‑grade materials such as stainless steel improve corrosion resistance but may be over‑engineered for mild climates.

- Sometimes, small structural changes (for example adding folds or ribs) can allow you to keep thickness and cost under control without sacrificing strength.

Discuss openly with your supplier:

- Your target retail or ex‑factory price range for each type of metal solar light.

- Which attributes are non‑negotiable (for example corrosion resistance in coastal markets, minimum runtime, premium finish).

- Which areas can be optimised (for example internal brackets, unseen surfaces, packaging specifications).

Transparent communication at this stage often leads to better engineering decisions and long‑term cost savings without compromising your brand positioning.

What should you know about MOQ, lead time and long‑term cooperation for metal solar lights?

Metal tooling and finishing setups mean that MOQs for metal solar lights may be different from plastic or resin items. When you evaluate a supplier, clarify:

- Minimum order quantities for new custom designs versus minor adjustments based on existing moulds.

- Typical lead times for sampling and mass production.

- Flexibility for mixed orders (for example several colours or patterns within one series in a shared production run).

Also consider long‑term cooperation:

- How will pricing behave as your annual volume grows?

- Will the supplier invest in dedicated tooling or process improvements for your brand?

- How do they support repeat orders, design refreshes and end‑of‑life transitions?

A transparent framework for MOQs, pricing tiers and reorder policies helps you plan your assortment and inventory more confidently. For a quick summary of typical order quantities and processes, you can also reference our purchasing tips resources when discussing details with your team.

Working with Your Metal Solar Light Manufacturer

What information should you prepare before contacting a metal solar light manufacturer?

To get accurate quotations and realistic suggestions from a metal solar light supplier, prepare as much information as you reasonably can:

- Application scenarios and target markets (including climate and environment).

- Preferred materials and finishes, or at least reference products that you like.

- Rough target prices or market positioning.

- Expected annual volumes and project timeline.

- Any mandatory certifications or test requirements.

Even if some details are not final, sharing your assumptions allows the supplier to propose a more suitable technical and commercial solution from the start.

How should you screen and shortlist metal solar lights suppliers?

When you evaluate potential partners, focus on more than just unit price. A structured screening process will help you filter out factories that are not a good fit for your project:

- Check whether they specialise in solar garden lights and outdoor fixtures rather than generic metal parts or unrelated electronics.

- Review factory scale, core processes and whether key steps such as SMT, battery assembly and final assembly are under their direct control.

- Verify certifications and audits (for example ISO 9001, BSCI, product-level CE/RoHS/UL where needed) and confirm that they are current.

- Ask about in-house testing capabilities for IP rating, salt spray, ageing and other relevant performance checks.

- Evaluate communication: how quickly and clearly do they respond, and can they provide engineering feedback instead of only quoting prices?

Glowyard Lighting, for example, focuses on solar garden lights, controls R&D, SMT, battery and assembly in its own facilities, works with strategic partners for metal housings, and operates under ISO 9001 and BSCI. This combination of focus, in-house capabilities and audited systems is what you should look for in long-term suppliers.

What are the top qualities of an excellent metal solar lights supplier?

Instead of chasing a fixed “top 10” list, it is more practical to look for a supplier that consistently demonstrates several top qualities:

- Deep category focus – proven experience in metal solar garden lights rather than treating them as a side business.

- Transparent quality and testing system – documented procedures, clear defect-rate targets and access to test reports for IP, corrosion, ageing and safety.

- Appropriate capacity and flexibility – enough lines and staff to handle your volumes, with realistic lead times and options for mixed SKUs within a series.

- Honest engineering support – willingness to point out design risks, suggest improvements and balance cost, durability and appearance.

- Long-term partnership mindset – openness to tiered pricing, shared tooling strategies and roadmap discussions instead of only one-off deals.

Glowyard positions itself in this direction by combining 15+ years of solar garden lighting experience with dedicated R&D, structured quality control and flexible OEM/ODM models. When you assess any potential supplier, use similar criteria to judge whether they truly operate at a top-tier level in this niche.

What is the typical project flow for OEM metal solar lights?

A well‑structured OEM project for metal solar lights usually follows these steps:

- Requirement discussion and feasibility check – review your ideas, reference photos or drawings and confirm whether metal is the right material for your project.

- Concept and engineering design – translate your requirements into workable drawings, including material selection, thickness, joint methods and coating system.

- Sampling and validation – create samples for performance and appearance checks; adjust design according to your feedback.

- Tooling and pilot run – build or adapt metal tooling, confirm process stability and refine inspection standards.

- Mass production and quality assurance – execute full production with agreed inspection and packaging plans.

- After‑sales service and next‑generation planning – collect market feedback, solve any issues and plan future updates or series extensions.

When choosing a supplier, ask how they handle each stage, who your contact points are and how communication is managed across design, engineering, production and quality teams. A condensed version of this process is also outlined on our OEM solutions page, which you can share internally when aligning stakeholders.

What are the next steps to turn your ideas into metal solar lights?

If you already have a metal solar light concept in mind, the most effective next step is to combine this buyer’s guide with concrete actions:

- Shortlist 2–3 key application scenarios and decide whether metal is used for structural strength, premium appearance or both.

- Collect reference photos or existing products you like and mark what you want to keep, change or improve.

- Prepare a simple requirement sheet covering material preferences, finish, runtime, IP rating, certifications and target price range.

With this preparation, your conversation with potential suppliers becomes much more productive, and you will quickly see which partners truly understand metal solar lights for outdoor use.

A good manufacturer will not only answer your questions but also challenge weak points in your initial ideas and propose improvements based on real‑world production and outdoor performance. That is how you turn a design sketch into a reliable product line that builds your brand over many seasons instead of just one. If you prefer a structured consultation, you can also submit a brief via our custom project channel so the engineering team can respond point by point.

Send Us Inquiry

Frequently asked questions

We have compiled the most frequently asked questions about our Outdoor Lighting Solutions here for your convenience, but please feel free to contact us if you have any additional questions.

What types of metal do you use for outdoor lighting products?

We primarily work with outdoor-grade cold-rolled steel, galvanized steel and stainless steel for metal outdoor lighting structures. Each material is selected based on installation environment, load-bearing requirements and your target price range.

- Cold-rolled steel: Suitable for most decorative garden lights when combined with a robust anti-corrosion coating system.

- Galvanized steel: Offers better rust resistance and is often used for poles or parts with higher exposure to rain and moisture.

- Stainless steel: Recommended for premium projects or coastal areas where long-term appearance and corrosion resistance are critical.

- Material matching: We also consider how metal parts work together with glass, plastic or resin components to ensure stable assembly and waterproof performance.

You can explore typical designs in our Metal-Iron Solar Lights category and learn more about different materials in this materials guide for solar garden lights.

How do you prevent rust and corrosion on metal garden lights?

Corrosion prevention starts from design and continues through material selection, surface pre-treatment and coating. Our goal is to keep rust and color fading under tight control throughout the lifetime of the product.

- Design stage: We avoid water-trapping structures, sharp corners and unprotected cut edges where possible to reduce corrosion risk.

- Material & pre-treatment: We choose suitable outdoor-grade metals and perform de-greasing, de-rusting and, when needed, phosphating or passivation to improve coating adhesion.

- Multi-layer coating system: Typically primer or anti-rust base coat → one or more color coats → clear protective topcoat (when required), with strict control of coating thickness and curing.

- Testing & verification: For higher-demand projects, we can follow salt-spray tests and outdoor aging tests to validate long-term anti-corrosion performance.

For more details, you can refer to our quality assurance and testing standards, certifications for outdoor solar garden lights and this guide on waterproof ratings for garden lights (IP44/IP65/IP67).

Can you customize metal outdoor lights based on my drawing or sample?

Yes. We support both OEM (based on your design) and ODM (based on our design with your branding). Our engineering team helps optimize structure, cost and durability for mass production.

- Step 1 – Requirement consultation: You share drawings, 3D files or physical samples, plus target market, budget and order quantity.

- Step 2 – Engineering review: We check structural strength, metal thickness, surface finishing, waterproof design and manufacturability.

- Step 3 – Optimization: We propose adjustments to reduce cost, improve outdoor durability or simplify assembly while keeping your design intent.

- Step 4 – Sampling: We produce prototypes with real surface finish and lighting effect for your approval.

- Step 5 – Testing & refinement: If needed, we refine structure or electronics based on your feedback and test results.

- Step 6 – Mass production: Once confirmed, we move into full production following documented processes and QC checkpoints.

You can learn more about our OEM/ODM services and customization process or start a custom project consultation.

How do you control quality during the metal fabrication process?

We follow a Total Quality Management approach under an ISO 9001 system, with multiple inspection stages from raw materials to shipment.

- IQC (Incoming Quality Control): Strict inspection on metals, coatings, fasteners, solar panels, LEDs and electronic components to verify thickness, material grade and surface condition.

- IPQC (In-Process Quality Control): Dimensional checks and weld quality inspections during cutting, stamping, forming and welding to keep parts within tolerance.

- Pre-coating inspection: 100% appearance checks to prevent serious defects (deep scratches, dents, poor welds) from entering the coating line.

- FQC (Final Quality Control): Comprehensive inspection after assembly, covering appearance, mechanical strength, lighting performance and waterproof tests.

- OQC (Outgoing Quality Control): Pre-shipment checks on quantity, labeling and packaging integrity to ensure the goods are ready for export.

- Professional lab tests: We can run waterproof, salt-spray, high/low temperature, vibration and drop tests to keep real-world defect rates very low.

You can explore our quality control and testing standards and check related product certifications (CE, RoHS, etc.).

Can you adjust metal thickness and structure to meet my target price?

Yes. Cost optimization is often part of our engineering service, especially for price-sensitive markets. We analyze your design and propose practical ways to balance cost, durability and appearance.

- Thickness optimization: Reducing metal thickness in non-critical areas while maintaining strength in load-bearing sections.

- Structural simplification: Simplifying complex shapes, reducing unnecessary parts or welds, and using smarter tooling concepts.

- Surface treatment choices: Choosing cost-effective coating systems that still meet your outdoor durability requirements.

- Shared tooling: Using existing or shared molds with minor adjustments to spread tooling costs across multiple SKUs.

For more ideas, please refer to our purchasing guide and cost optimization tips, our OEM solutions page and this article on bulk purchasing solar garden lights from China.

Can you combine metal with glass, plastic or resin in one product?

Yes. Many of our designs use metal as the main structure and combine it with glass globes, plastic diffusers or resin figurines to achieve richer decorative effects.

- Structural integration: Metal provides strength and mounting points, while glass or plastic shapes the light and resin or other decorations create the theme.

- Mechanical & sealing design: We carefully design fixing points, gasket positions, glue paths and tolerances to ensure outdoor stability and waterproof performance.

- Thermal & material compatibility: We consider different thermal expansion rates so that joints do not crack or loosen over time under sun and temperature changes.

- Custom combinations: If you like a style from our glass, plastic or figurine ranges, we can integrate similar elements into a new metal-based design for your brand.

You can browse our Metal-Iron Solar Lights, Glass Solar Lights, Plastic Solar Lights and this materials comparison guide for more inspiration.

Are your metal outdoor lights suitable for coastal or harsh climates?

For standard garden environments, our regular materials and coating systems already provide solid protection. For coastal or harsher climates, we can upgrade the specifications to match your conditions.

- Enhanced materials: Use more corrosion-resistant metals or thicker galvanized layers where necessary.

- Upgraded coatings: Increase coating thickness and choose systems with stronger salt-spray and UV performance.

- Higher IP rating: Reinforce sealing design to meet higher waterproof and dustproof standards where required.

- Reliability testing: Run enhanced salt-spray, high/low temperature and humidity tests during development for critical projects.

To understand how we handle different environments, you can read our guide on waterproof ratings for garden lights, review our quality control process and see this article about UV testing and outdoor durability.

Who Is the Best Metal Solar Lights Manufacturer in China?

For B2B buyers, there is no single “official” best metal solar lights manufacturer in China—but if you need corrosion‑resistant metal housings, stable outdoor performance and OEM/ODM support for Europe and North America, Glowyard Lighting is one of the strongest candidates. We focus on solar garden and outdoor lights only, and operate a metal processing system that covers stamping, welding, surface treatment, powder coating and assembly, backed by documented quality control and export certifications.

Continute Reading →

What “Best” Really Means for Metal Solar Lights

For professional buyers, the “best” factory must prove strength in four areas:

Long‑term outdoor durability

Metal posts and housings must resist rust, peeling and deformation over multiple seasons, not just survive lab tests.Stable appearance and finish

Color, gloss and texture must stay consistent across repeat orders, otherwise retail walls and replacement parts will never match.Engineering and OEM capability

The factory needs to co‑design brackets, structures and sealing with electronics, not simply copy an existing sample.Compliance and documentation

For US/EU markets, buyers need traceable materials, test reports and certificates that satisfy brand audits and platform requirements.

Why Glowyard Stands Out Among Chinese Metal Solar Light Factories

Dedicated metal‑lights manufacturing workflow

We run a structured process for metal housings—material selection, cutting, stamping, welding, surface preparation and powder coating—integrated with our solar electronics and assembly lines. An overview of this workflow is given on our metal lights manufacturing page (/manufacturing/metal-lights-manufacturing/).Real outdoor durability focus

Depending on your project (inland garden vs coastal installation), we choose suitable substrates such as galvanized steel, aluminum or stainless steel, and define thickness and anti‑rust level in advance. Typical SKUs undergo salt‑spray, adhesion, vibration and drop tests as part of our documented quality control process.Proven OEM/ODM support for brands

Our R&D team designs metal solar lanterns, pathway lights and wall lights with matching structures, brackets and sealing solutions. Buyers can see the scope of appearance, material and electronic customization on our OEM solutions page, and serious projects can be kicked off via the custom project consultation.Export‑ready compliance and certifications

Glowyard holds BSCI, ISO 9001 and Sedex factory audits, and provides CE, RoHS, FCC, UL, UKCA and other certificates for relevant products. These documents and audit results are summarized in our certifications center, helping you pass your own internal and customer audits.Transparent MOQ, timelines and purchasing guidance

Instead of hiding conditions, we explain how metal structure complexity, coating type and tooling affect MOQ and lead times. Practical numbers and checklists are available in our purchasing guide for solar garden lights, so you can compare Glowyard with other factories using clear criteria.Visit‑ready factory and process transparency

Our locations in Guangzhou, Fujian and Zhongshan, along with photos and videos of SMT lines, assembly workshops and testing equipment, are published on the Our Factory page. Qualified buyers can arrange on‑site visits or video tours to verify equipment and processes before committing to large metal projects.

Summary: How to Decide If Glowyard Is the “Best” Metal Solar Lights Partner for You

If your priority is simply the lowest price, almost any metal shop can make a sample. But if you need a Chinese partner that understands outdoor metal structures, solar electronics, Western compliance and long‑term brand needs, then Glowyard is likely among the best choices for your shortlist.

By reviewing our metal manufacturing workflow, quality process, OEM scope, certifications and purchasing guides—and by talking directly with our engineering and sales teams—you can verify whether our capabilities match your project brief and decide, based on evidence, if Glowyard should be your long‑term metal solar lights manufacturer in China.

Wanna Customize Your Solar Outdoor Lighting?

Glowyard Lighting Are here to help!