UV Testing on Plastics for Outdoor Solar Lights

Sunlight makes garden solar lights shine — but it also damages them. UV rays break down plastics, fade colors, and reduce durability.

UV testing checks how plastics withstand years of sun exposure, ensuring outdoor solar lights stay bright, beautiful, and safe for long-term use.

Plastic Testing for Durability

When customers buy solar lights, they expect them to last through every season. In our factory at Glowyard Lighting, we make sure of this by performing rigorous UV aging tests that simulate years of outdoor exposure in just a few weeks.

Why is UV Testing Important for Outdoor Solar Lights?

UV rays slowly destroy plastic materials, reducing product lifespan and safety.

UV testing helps manufacturers predict material performance and improve plastic formulations for better color retention and mechanical strength.

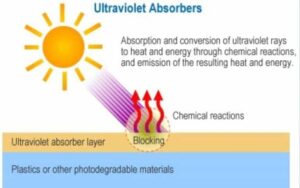

ultraviolet absorbers

The Science Behind UV Damage

When plastics are exposed to UV radiation, chemical bonds break down — a process called photo-degradation. This causes fading, brittleness, and loss of transparency. For solar garden lights, such changes affect both appearance and performance.

| Type of Damage | Cause | Result on Product |

|---|---|---|

| Color Fading | UV-induced pigment breakdown | Dull or yellowish look |

| Cracking | Loss of polymer flexibility | Structural failure |

| Reduced Brightness | Degradation of diffuser lenses | Lower light output |

At Glowyard Lighting, we test every plastic component under simulated sunlight (usually 340 nm wavelength) using xenon arc or UV fluorescent lamps. This helps us ensure the materials can endure up to 5 years of outdoor exposure.

How Is UV Testing Performed on Plastic Components?

Manufacturers use accelerated weathering tests to replicate years of sunlight in a short time.

The most common methods include xenon arc testing and UV fluorescent lamp testing, both following global standards like ASTM G155 and ISO 4892.

uv accelerated weathering tester

Testing Methods and Parameters

UV testing machines simulate outdoor sunlight and humidity cycles. Materials are exposed to light and water spray alternately to measure degradation.

| Testing Method | Description | Duration | Standard |

|---|---|---|---|

| Xenon Arc | Full-spectrum sunlight simulation | 500–2000 hours | ASTM G155 |

| UV Fluorescent | UV-B and UV-A light exposure | 500–1000 hours | ISO 4892-3 |

| Outdoor Exposure | Real-time aging test | 6–24 months | ASTM G7 |

After testing, we check for color change, gloss reduction, surface cracking, and mechanical strength. This process allows us to compare different formulations and choose the one that best resists UV damage.

What Types of Plastics Perform Best Under UV Exposure?

Not all plastics can handle the sun equally well.

Materials like polycarbonate (PC), acrylic (PMMA), and UV-stabilized ABS perform better than standard plastics due to added stabilizers and coatings.

uv stablizier

Comparing Plastic Types for Solar Lights

When designing solar garden lights, material choice determines both appearance and longevity. Here’s a quick comparison:

| Plastic Type | UV Resistance | Transparency | Cost | Ideal Use |

|---|---|---|---|---|

| Polycarbonate (PC) | Excellent | High | Medium | Lenses, covers |

| Acrylic (PMMA) | Very good | Excellent | Medium | Decorative parts |

| UV-stabilized ABS | Good | Opaque | Low | Stakes, housings |

| Polypropylene (PP) | Fair | Opaque | Low | Non-structural parts |

In our factory, we often mix UV stabilizers and antioxidants during plastic injection to enhance protection. For high-end models, we also apply anti-UV coatings, ensuring both durability and aesthetic appeal even after prolonged exposure.

How Does UV Testing Support Quality Control in Solar Light Production?

Testing helps detect weaknesses before products reach customers.

By integrating UV testing into production, manufacturers reduce warranty claims, improve customer satisfaction, and strengthen brand trust.

methods of predicting plastics reaction to uv

From Lab to Field: Glowyard’s Approach

At Glowyard Lighting, our UV testing is not just a formality — it’s a promise of reliability. Every batch of plastic parts undergoes random sampling and accelerated aging tests. If materials fail, they are reformulated before production resumes. This quality loop minimizes product failure in real outdoor conditions.

| Step | Process | Goal |

|---|---|---|

| 1 | Material selection | Choose UV-resistant polymers |

| 2 | Accelerated aging test | Simulate long-term exposure |

| 3 | Data analysis | Measure color and strength retention |

| 4 | Quality adjustment | Modify formulations if needed |

| 5 | Final inspection | Approve for mass production |

Our export clients in Europe and North America often request certification reports confirming UV resistance. We provide detailed documentation to support their compliance with safety and environmental regulations.

Conclusion

UV testing ensures solar lights not only shine bright but also last long under the sun — a small test that makes a big difference in product trust and longevity.