“Specializing in solar garden lights wholesale, with five production lines, committed to providing high-quality, cost-effective, and innovative lighting solutions for Europe, North America, Russia, and Australia markets.”

Wholesale Stainless Steel Solar Lights combine modern aesthetics with superior durability. These premium fixtures feature corrosion-resistant stainless steel construction that withstands harsh weather while maintaining sleek, contemporary appeal. Glowyard Lighting manufactures wholesale stainless steel solar lights with precision OEM/ODM customization. We offer custom grades, finishes, polishing levels, and design options for your premium metal lighting product line.

Steel the show with custom stainless steel solar light manufacturing.

2025 lastest Full Product Catalogue

Haven't found your ideal Lighting design?

As a B2B buyer looking to source solar stainless steel path lights from China factories, solar garden stainless steel outdoor lights, or stainless steel path light manufacturers, you need comprehensive information to make informed purchasing decisions. This guide answers the key questions that wholesalers, landscape contractors, retailers, and distributors commonly ask when sourcing these premium functional lighting products from Chinese manufacturers.

At Glowyard Lighting, with over 15 years of experience as a China-based solar stainless steel path light factory and solar garden stainless steel outdoor light manufacturer, we’ve worked with international buyers, landscape professionals, and distributors across North America, Europe, and Asia-Pacific.

In this guide:

China produces over 50% of the world’s stainless steel, making it the global leader in stainless steel manufacturing. This dominance translates directly into advantages for B2B buyers sourcing solar stainless steel path lights and solar garden stainless steel outdoor lights from China factories.

Cost Competitiveness – China factories offer 30-50% lower costs than Western manufacturing for stainless steel solar lights. Economies of scale, efficient fabrication systems, and comprehensive supply chains create significant pricing advantages for both stainless steel path light factories and solar garden outdoor light manufacturers.

Manufacturing Expertise – Chinese factories have decades of experience with stainless steel fabrication, welding, and finishing. Advanced laser cutting, precision forming, and quality welding capabilities ensure premium products whether you’re sourcing path lights or garden outdoor lights.

Integrated Supply Chain – China offers complete vertical integration from raw stainless steel to finished solar lights. Solar panels, LED components, batteries, and stainless steel materials are all available domestically, reducing costs and lead times for solar stainless steel path light factories.

China produces approximately 70% of global solar garden lights, including premium stainless steel varieties. This established infrastructure means:

Learn about decorative outdoor solar garden lights

Contemporary Modern Path Lights – Clean lines, minimalist design, brushed stainless steel finishes. These solar stainless steel path lights complement modern architecture and command premium positioning.

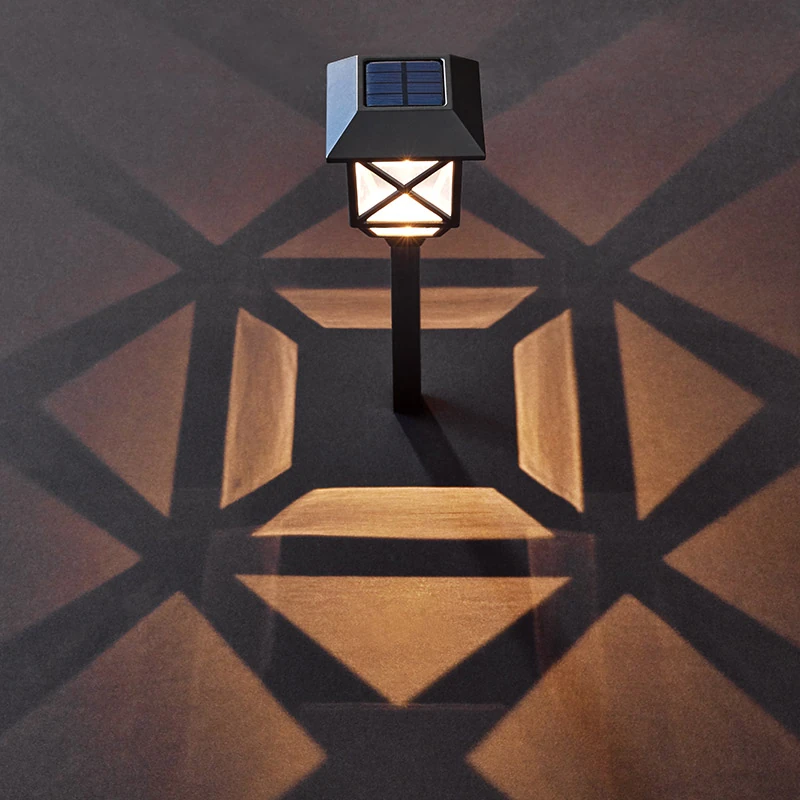

Traditional Classic Path Lights – Timeless lantern-style designs with polished stainless steel. Broad market appeal for residential and commercial pathway applications.

Commercial Bollard Path Lights – Heavy-duty construction, 24-48 inch heights, designed for high-traffic areas. Stainless steel path light factories produce these for municipal and commercial projects.

Low-Profile Path Markers – 6-12 inch heights, subtle pathway marking, modern aesthetic. Popular for contemporary landscapes.

Garden Stake Lights – Ground-inserted stainless steel lights for flower beds and garden borders. Solar garden stainless steel outdoor light factories produce various heights and styles.

Wall-Mounted Outdoor Lights – Stainless steel fixtures for fences, walls, and building exteriors. Durable construction for permanent outdoor installation.

Post-Top Garden Lights – Decorative stainless steel lights for garden posts and pillars. Statement pieces for upscale residential and commercial properties.

Landscape Accent Lights – Spotlights and uplights with stainless steel housings for tree and shrub illumination.

| Category | Lumens | Runtime | Best Applications | |———-|——–|———|——————-| | Ambient | 5-15 | 10-12 hrs | Decorative accent | | Functional | 15-50 | 8-10 hrs | Pathway safety | | High Performance | 50-100 | 6-8 hrs | Commercial areas | | Ultra-Bright | 100-200 | 4-6 hrs | Security lighting |

304 Stainless Steel (Standard Grade)

316 Stainless Steel (Marine Grade)

201/202 Stainless Steel (Budget Grade)

Material Certificates – Request mill certificates from China stainless steel path light factories verifying exact grade composition.

XRF Testing – X-ray fluorescence testing identifies exact stainless steel composition. Third-party testing available.

Magnet Test – 304 and 316 grades are non-magnetic or weakly magnetic. Strong magnetic attraction indicates lower grades (201/202).

Visual Inspection – Quality welding, consistent finish, adequate material thickness (0.5-1.0mm minimum).

Waterproof Ratings – IP65 minimum for path lights, IP67 preferred for ground-level installation. Learn about waterproof ratings

Certifications Required – CE (Europe), RoHS (hazardous substances), FCC (US electromagnetic). View certifications

Quality Management – ISO 9001 certified factories ensure consistent production standards. Learn about quality control

Online B2B Platforms

Trade Shows

Direct Factory Search

Stainless Steel Expertise

Production Capacity

Quality Systems

Learn about metal manufacturing

Competitive Pricing – China solar stainless steel path light factories offer 30-50% lower costs than Western alternatives due to:

Flexible MOQs – Order quantities range from 100-1000 units depending on factory type:

Scalability – China factories can rapidly scale production for solar garden stainless steel outdoor lights from samples to mass production.

Customization – Full OEM/ODM services including:

Speed – Fast production timelines:

Integrated Supply – Complete sourcing within China:

Logistics – Established export infrastructure with experienced freight forwarding and customs documentation.

Material Verification

Sample Approval

Specification Agreement

Production Monitoring

In-Process Inspection

Final Inspection

Third-Party Inspection

Housing Design – Custom shapes, dimensions, and aesthetic designs for solar stainless steel path lights and garden outdoor lights.

Finish Options

Size and Configuration – Custom heights, diameters, and configurations for specific project requirements.

Stainless Steel Grade Selection – Choose between 304 standard grade or 316 marine grade based on application environment.

Solar System Upgrades

LED Specifications

Logo Integration – Laser engraving or embossing on stainless steel housing.

Custom Packaging – Branded boxes, marketing materials, multilingual instructions.

Private Labeling – Complete white-label solutions for your brand.

Explore OEM/ODM solutions

Long-Term Perspective – Chinese business culture values long-term partnerships. Invest in relationship building for better pricing, priority production, and quality attention.

Face-to-Face Meetings – Visit factories when possible, or arrange video calls. Trade show meetings are excellent opportunities.

Cultural Understanding – Patience, respect, and indirect communication styles are valued. Relationship often comes before business transactions.

Clear Specifications – Provide detailed written documentation including:

Regular Updates – Schedule regular check-ins during production. Proactive communication prevents problems.

Prompt Responses – Reply quickly to maintain momentum and show professionalism.

Win-Win Approach – Focus on mutual benefit rather than aggressive price negotiation.

Volume Leverage – Larger orders and long-term commitments earn better pricing.

Payment Terms – Standard terms are 30% deposit, 70% before shipment. Negotiate based on relationship history.

Accepting Lower Grade Stainless – Verify 304 or 316 grade before production. 201/202 substitution is common with unscrupulous suppliers.

Not Verifying Material Grade – Always request material certificates and consider third-party testing.

Ignoring Welding Quality – Poor welds cause corrosion and structural failure. Inspect welding quality on samples.

Price-Only Focus – Lowest price often means lowest quality. Consider total cost including quality issues and replacements.

Skipping Samples – Always test samples before production orders. Verify stainless steel grade and workmanship.

No Factory Verification – Verify factory credentials, visit if possible, check references.

Unclear Specifications – Detailed specifications prevent misunderstandings. Document everything in writing.

Inadequate Lead Time – Plan 60-90 days total (production + shipping). Build buffer for delays.

No Quality Inspection – Pre-shipment inspection is essential. Consider third-party services.

Poor Documentation – Maintain complete records of specifications, communications, and agreements.

Glowyard Lighting is a professional China solar stainless steel path light factory and solar garden stainless steel outdoor light manufacturer with 15+ years of experience. We serve 500+ international clients across 50+ countries. Read more about Glowyard

Stainless Steel Expertise

Manufacturing Capacity

Visit our factory facilities

Quality Systems

Learn about quality control

Certifications

View certifications

Reliable China Partner – 15+ years export experience with proven track record for solar stainless steel path lights and solar garden stainless steel outdoor lights.

Verified Stainless Steel Quality – Both 304 and 316 grades with complete material certification and quality assurance.

Competitive Factory Pricing – Direct factory advantages without trading company markups.

Professional Service – English-speaking team, 24-hour response, technical support, export expertise.

Customization Capabilities – Full OEM/ODM services for custom stainless steel path light designs.

Q: How can I verify stainless steel grade from China factories?

A: Request material certificates from the steel supplier. Third-party XRF testing identifies exact composition. Magnet test helps (304/316 are non-magnetic). Glowyard provides complete material certification.

Q: What’s the price difference between 304 and 316 stainless steel?

A: 316 grade costs 20-30% more than 304 due to molybdenum content. For path lights: 304 grade approximately $30-$60 FOB, 316 grade $40-$80 FOB. 316 is essential for coastal/saltwater environments.

Q: What’s the typical MOQ from China stainless steel path light factories?

A: Factory direct: 500-1000 units. Manufacturers: 300-500 units. Wholesale: 100-300 units. Glowyard offers flexible MOQs starting from 300 units.

Q: How long does production take?

A: Standard production: 30-45 days. Custom products: 45-60 days. Samples: 7-10 days. Add 25-40 days for sea freight. Plan 60-90 days total.

Q: Is it safe to source from China?

A: Yes, with proper due diligence. Verify factory credentials, use Trade Assurance or L/C, conduct quality inspections, test samples first. Glowyard has 15+ years reliable export experience.

Q: What certifications should China factories have?

A: CE (Europe), RoHS, FCC (US), ISO 9001 (quality management). Stainless steel material certificates essential. Glowyard maintains all necessary certifications.

Q: Should I visit the factory?

A: Highly recommended if possible. Verify stainless steel production capability, assess quality systems, build relationships. Virtual factory tours also available. Glowyard welcomes factory visits.

—

Ready to source solar stainless steel path lights from China? Contact Glowyard Lighting today for factory pricing, samples, and customization options. As a leading China solar stainless steel path light factory and solar garden stainless steel outdoor light manufacturer, we’re your trusted partner for premium stainless steel outdoor lighting.

Send Us Inquiry

“Specializing in solar garden lights wholesale, with five production lines, committed to providing high-quality, cost-effective, and innovative lighting solutions for Europe, North America, Russia, and Australia markets.”

Scan By WeChat

Scan By WhatsApp

Fill Out The Form Below Or Reach Out To Us Directly

© 2020-2025 Glowyard Is A Trademark Of Soume Lighting Industry and Trade Co., Ltd. All Rights Reserved.

WhatsApp us

Plan Your Next Order Early – Don’t Miss the Peak Season!

- Free samples for qualified buyers

- OEM & ODM for solar garden lights

- Full pre-shipment QC and warranty support