“Specializing in solar garden lights wholesale, with five production lines, committed to providing high-quality, cost-effective, and innovative lighting solutions for Europe, North America, Russia, and Australia markets.”

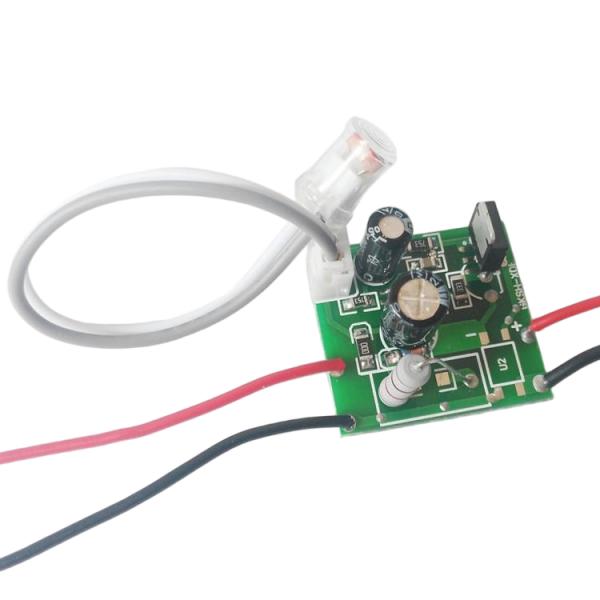

Integrated assembly of solar panels, battery boxes, sensors and control systems for stable outdoor performance.

In many garden solar lights on the market, components are sourced separately and assembled with minimal system verification.

This approach often leads to inconsistent brightness, short lifespan, and seasonal failures.

We take a system-based approach.

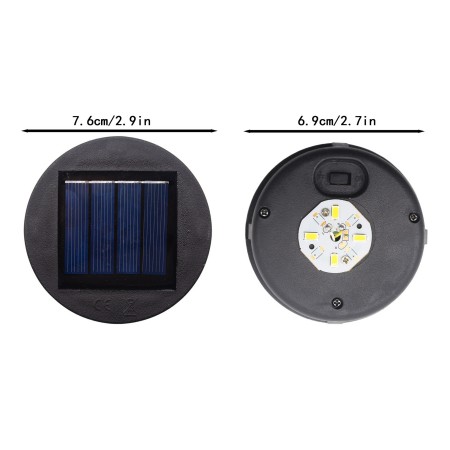

A complete solar power module includes:

Only when these elements are properly matched and assembled can a solar light perform reliably in real outdoor environments.

At Glowyard, we do not assemble solar lights by combining off-the-shelf parts.

We design and assemble complete solar power modules with full responsibility for performance.

If you are looking for garden solar lighting solutions with stable quality, predictable performance, and reduced after-sales risk, our engineering team is ready to support your project.

Contact us to discuss your solar power module requirements or request a tested sample.

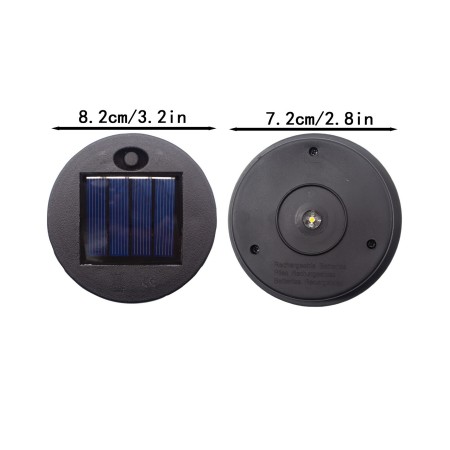

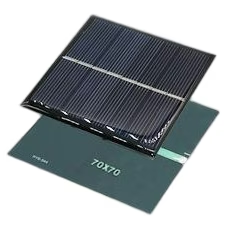

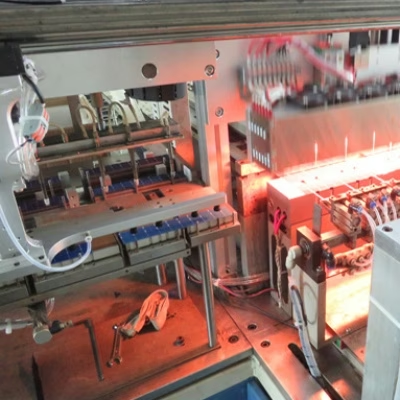

Our epoxy solar panels are produced through an integrated in-house process, covering cell testing, cutting, welding, encapsulation, and final inspection.

Each production step is strictly controlled to ensure consistent electrical output, structural stability, and long-term outdoor durability.

From single-cell testing and laser cutting to manual soldering, epoxy encapsulation, and finished product inspection, every panel is verified before assembly into solar lighting systems.

This process allows us to minimize performance variation, reduce defect rates, and deliver stable solar solutions for large-volume B2B orders.

How Solar Panels for Garden Lights Are Made – Inside Glowyard’s Manufacturing Process

Solar garden lights rely heavily on the stability of their solar modules.

STEP 01

STEP 02

STEP 03

STEP 04

STEP 05

STEP 06

STEP 07

STEP 08

STEP 09

STEP 10

Before any GlowYard outdoor light leaves the factory, its solar panel goes through a dedicated quality-control sequence designed for long-term outdoor performance. From electrical stability to UV resistance and waterproof sealing, each step eliminates potential failure points so your customers receive solar lights that charge faster, last longer, and stay stable in every season.

Purpose: Ensures consistent voltage, amperage, and overall charging efficiency.

Purpose: Validates long-term durability against sunlight, heat, and outdoor environments.

Purpose: Prevents moisture damage and ensures reliable outdoor performance.

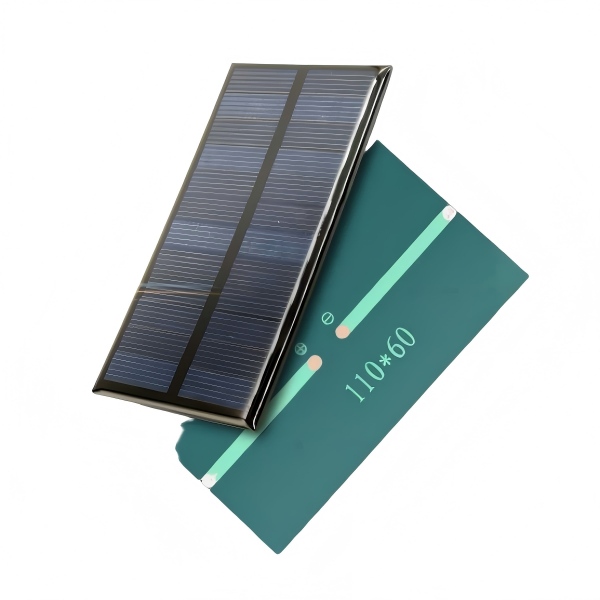

Battery performance directly affects lighting duration, product lifespan, and safety.

We select batteries based on:

Oversized batteries increase cost without improving performance.

Undersized batteries shorten lighting time and reduce lifespan.

Balanced matching is essential.

During assembly, batteries are integrated with:

This protects the battery from premature degradation and ensures long-term reliability.

The control board determines how efficiently solar energy is stored and used.

Our control system manages:

By optimizing control logic, we ensure energy is used efficiently rather than wasted.

Sensors play a critical role in lighting behavior and user experience.

Depending on product requirements, we integrate:

All sensor components are selected based on response accuracy, stability, and outdoor durability.

The battery box protects all internal components from environmental damage.

Our battery box design focuses on:

Most outdoor solar light failures originate from moisture entering the battery box.

To prevent this, we apply:

This ensures reliable performance under rain, humidity, and temperature changes.

Before integration into finished solar lights, each solar power module undergoes:

By controlling solar power module assembly in-house, we help buyers avoid:

Usually caused by mixed-quality solar panels or inconsistent system matching, resulting in different charging and lighting performance across products in the same order.

Results from unstable light sensors or poorly calibrated control boards, causing lights to turn on too early, too late, or fail to respond consistently.

Often due to poor battery protection, moisture ingress, or improper charging logic, which accelerates battery aging and leads to early product failure.

Typically caused by component substitution or lack of system-level verification between sampling and mass production stages.

We support OEM and ODM projects with flexible solar power module design, including:

Solar panel dimensions and output are customized based on product structure, target market sunlight conditions, and required lighting duration to ensure efficient charging without unnecessary cost increase.

Battery type and capacity are selected according to panel output, lighting time requirements, safety standards, and climate conditions to achieve stable performance and long service life.

Charging logic, lighting behavior, and sensor sensitivity are configured to match usage scenarios, ensuring accurate response, efficient energy use, and consistent operation across production batches.

The battery box structure and internal layout are optimized to improve waterproof sealing, heat dissipation, and component stability, reducing failure risks in long-term outdoor environments.

Our factory holds BSCI, ISO 9001, and Sedex audits, and our products comply with CE, RoHS, FCC, UL, UKCA and more.

Our solar power modules are engineered to perform across different regions:

System-level design ensures stable performance regardless of climate variation.

A practical guide helping B2B buyers evaluate solar power module quality, system design, and supplier capability—beyond individual components.

A solar power module is the integrated energy system of a solar garden light. It includes the solar panel, battery, control board, sensors, and sealed battery box. Its performance determines charging efficiency, lighting duration, stability, and overall product lifespan.

Most solar light failures come from poor system integration rather than defective parts. Even high-quality panels or batteries will underperform if voltage, current, and control logic are mismatched. Assembly quality defines how reliably all components work together.

Poor integration often leads to uneven brightness, short lighting duration, incorrect sensor behavior, battery swelling, and early product failure. These issues increase return rates and negatively affect brand reputation.

Solar panel size, material, and output must be matched with battery capacity and system load. Oversized panels may overcharge batteries, while undersized panels result in insufficient charging. Stable output is more important than peak wattage.

Epoxy panels are low cost but degrade quickly under UV exposure. PET panels offer improved durability with moderate cost. Tempered glass panels provide the highest UV resistance and long-term stability for premium outdoor solar lights.

Buyers should focus on real outdoor charging performance rather than laboratory peak values. Consistent voltage under low-light conditions is more important than maximum output under ideal sunlight.

Battery type and capacity directly affect runtime and cycle life. Incorrect matching causes shallow charging, deep discharge, or thermal stress. Different batteries such as Li-ion, LiFePO₄, and NiMH require different control strategies.

The control board manages charging current, over-discharge protection, sensor logic, and energy distribution. It functions as the energy management center, not a simple on/off switch.

Poor control logic leads to battery damage, unstable brightness, false sensor triggering, and inconsistent performance between batches. These issues often appear only after extended outdoor use.

Sensors determine when the light turns on and off. Poor sensitivity may cause daytime lighting or delayed activation at dusk. Stable sensor calibration ensures consistent behavior in different environments.

The sealed battery box protects internal electronics from water, dust, insects, and temperature changes. Weak sealing leads to corrosion, short circuits, and early system failure even when internal components are high quality.

For garden solar lights, an IP65 rating or higher is recommended. Consistent sealing during mass production is as important as passing laboratory waterproof tests.

Buyers should request system-level testing such as charging efficiency, lighting duration, sensor response, waterproof inspection, and aging simulation. Component certificates alone are not enough.

Samples are often assembled manually with extra attention. Without standardized assembly and testing processes, bulk production introduces variability and hidden defects.

Buyers should ask whether solar panel assembly, battery box sealing, control board programming, and final testing are done in-house. Internal control reduces inconsistency and accountability gaps.

Proper customization allows correct matching of panel output, battery capacity, and control logic. Cosmetic customization without system redesign increases the risk of long-term failure.

Reasonable customization includes adjusting panel size, selecting battery type, tuning control logic, and optimizing housing structure. Extreme cost reduction without recalculation often compromises lifespan.

The best approach is optimizing system efficiency rather than downgrading individual components. A balanced module reduces warranty issues and long-term return costs.

Buyers should request system wiring diagrams, charging curves, test reports, and aging test summaries. Transparent documentation indicates real engineering capability.

In-house testing identifies system-level weaknesses before shipment and ensures each batch meets the same functional standard rather than relying on visual inspection only.

The biggest risk is assuming certified components guarantee performance. Without system-level engineering, certified parts can still fail in outdoor conditions.

Buyers should look for clear explanations of system design logic instead of marketing claims. Suppliers who understand energy flow, protection mechanisms, and failure modes are more reliable partners.

End users evaluate the final product, not its components. Consistent multi-season performance builds trust, reduces complaints, and strengthens brand value.

A solar power module is a complete engineered system, not a parts list. Buyers who prioritize integration, testing, and energy management achieve lower return rates and more stable long-term sales.

Send Us Inquiry

Wanna Customize Your Solar Outdoor Lighting?

Glowyard Lighting Are here to help!

“Specializing in solar garden lights wholesale, with five production lines, committed to providing high-quality, cost-effective, and innovative lighting solutions for Europe, North America, Russia, and Australia markets.”

Scan By WeChat

Scan By WhatsApp

Fill Out The Form Below Or Reach Out To Us Directly

© 2020-2025 Glowyard Is A Trademark Of Soume Lighting Industry and Trade Co., Ltd. All Rights Reserved.

WhatsApp us

Plan Your Next Order Early – Don’t Miss the Peak Season!

- Free samples for qualified buyers

- OEM & ODM for solar garden lights

- Full pre-shipment QC and warranty support