Our Integrated Outdoor Lighting Manufacturing System

Glowyard operates a complete outdoor lighting manufacturing system, specializing in solar-powered garden, decorative and landscape lights. From design and tooling to metal/plastic/resin/glass parts, electronics, surface finishing, assembly and testing, we control every key process in-house. With 15+ years of experience and dedicated workshops, we deliver stable quality, flexible MOQs and reliable lead times for global brands and importers.

Our Manufacturing Capabilities

Glowyard’s vertically integrated manufacturing covers every stage of outdoor lighting production, from concept to finished product. Explore our specialized processes and workshops below.

Industrial design, structure, electronics and optics—turning concepts into manufacturable outdoor lights

Cutting, welding, grinding and rust‑prevention for durable outdoor lamp posts and frames.

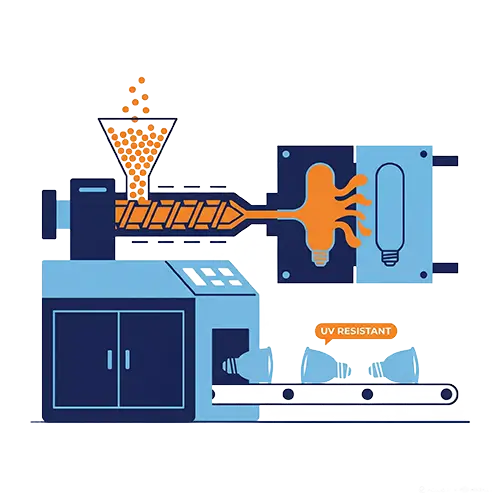

UV-resistant housings and diffusers with strict dimensional control.

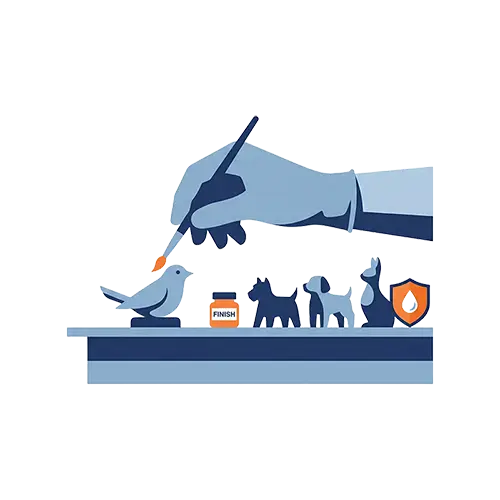

Decorative figures with hand‑painting and weather-resistant detailing.

Glass shade forming, grinding, sandblasting and structure integration.

Surface Finishing & Coating

Spraying, powder coating and UV‑resistant finishes for outdoor durability.

SMT & Electronics Assembly

In‑house SMT lines for LED drivers, solar controllers and sensor circuits.

Battery Pack Assembly & Testing

Cell sorting, pack assembly and capacity testing for stable runtime.

Final Assembly & Quality Control

Complete assembly, sealing and weatherproof testing before packaging.

Outdoor Lighting Manufacturing Process

From raw material selection to global delivery, every outdoor lighting product follows our proven 6-step manufacturing workflow. Each stage is designed to ensure consistent quality, outdoor durability and on-time delivery for customers worldwide.

- Step 01

Material Sourcing

Raw Materials Selection:

- High‑grade metals, UV-resistant plastics, polyresin and glass components

- Monocrystalline solar panels and high-efficiency LEDs

- Lithium batteries specifically designed for outdoor use

Quality Control:

- Strict IQC inspection to verify material specifications

- Durability testing for extreme weather (high temp, humidity, salt spray, UV)

- Certified supplier relationships with regular audits

- Step 02

Structural Manufacturing

Multi‑Material Processing:

- Metal: Cutting, stamping, welding and grinding to precise dimensions

- Plastic: Injection molding with UV-stabilized materials

- Resin: Custom mold casting with hand-finishing details

- Glass: Forming, annealing and edge-grinding for safety

Quality Assurance:

- Strict dimensional tolerances for outdoor lighting requirements.

- Material consistency checks at every manufacturing stage

- Step 03

Surface Finishing

Multi‑Layer Coating Process:

- Metal: Rust removal → Grinding → Primer → Color coat → UV-resistant clear coat

- Plastic: Spray painting or powder coating for durability

- Resin: Hand-painting with weather-resistant pigments + protective varnish

- Glass: Sandblasting or acid-etching for decorative effects

Outdoor Performance:

- Corrosion-resistant and fade-resistant surfaces

- Maintains appearance through years of outdoor exposure

- Step 04

SMT & Modules

SMT Electronics Assembly:

- Automated pick-and-place for LED drivers, solar charge controllers and sensors

- Reflow soldering + Automated Optical Inspection (AOI)

- Functional testing for every PCB board

SMT Electronics Assembly:

- Lithium cell sorting by capacity + Pack assembly with protection PCBs

- Charge/discharge performance testing

- LED modules with heat sinks tested for brightness, color temp and beam angle

- Step 05

Assembly & Testing

Final Assembly:

- Integration of housings, solar panels, LED modules, battery packs and control boards

- Sealing with gaskets and adhesives to achieve IP44/IP65 waterproof ratings

- Following detailed work instructions for consistency

Comprehensive Testing:

- Functional testing: Light-on verification, sensor response, mode switching

- Waterproof immersion tests + High/low temperature aging

- Waterproof immersion tests + High/low temperature aging

- Step 06

Packing & Shipping

Professional Packaging:

- Drop-tested cartons with protective foam inserts

- SKU, batch number and compliance marks (CE, RoHS) for traceability

- Designed to withstand international shipping and courier handling

Global Logistics:

- FIFO warehouse management with 100+ in-stock SKUs

- On-site container loading with customs documentation

- Shipping from Guangzhou, Shenzhen or Xiamen ports worldwide

Industry Pain Points

in Solar Garden Lights Manufacturing

Choosing the right manufacturing partner is not only about price. Many buyers struggle with:

Inconsistent quality

First shipment is fine, but repeat orders change in brightness, color, or runtime.

Hidden costs & Long Shipping

Extra tooling, packaging or testing fees appear late; delivery gets delayed in peak season.

Over‑promised specs

Claimed runtime, IP rating, or material thickness on paper do not match real products.

Poor transparency

Factories switch solar panels, batteries or LEDs without notice, making quality and certification hard to control.

To learn how to avoid these issues, read our purchasing guide for solar garden lights.

How Glowyard Solves These Problems

We designed our manufacturing model to address these common risks:

Transparent, asset‑light structure

R&D, SMT, battery and assembly are in‑house; housings come from strategic partners, giving better cost control and flexibility.

Documented manufacturing process

Clear steps from IQC, SMT and assembly to testing and packaging, so buyers know exactly how orders are built.

Dedicated flows for different materials

Separate processes for resin, metal and glass models to keep appearance and structure consistent.

Clear specifications & change control

Agreed specs, component lists and change approval before we adjust any key material or electronic part.

what makes us different

The values we live by

Vertically Integrated Production

All key processes in‑house—no scattered subcontractors.

Multi‑Material Capability

Metal, plastic, resin and glass in one factory system.

Specialized

15+ years focused on solar-powered outdoor lighting expertise.

Flexible OEM & ODM

Trial orders from 50 pcs, 7–10 day prototyping.

ISO 9001 Quality System

Full‑process control with outdoor-specific reliability testing.

Transparent Lead Times

25–35 days bulk lead time with clear scheduling.

Certified for Global Markets

Our factory holds BSCI, ISO 9001, and Sedex audits, and our products comply with CE, RoHS, FCC, UL, UKCA and more.

Purchasing Tips for Importers & Brand Owners

A few practical rules help you reduce risk and total cost:

Match customization level

Use simple appearance tweaks for 50–100 pcs trials; reserve deep structural or electronic changes for 300–500 pcs and above.

Plan around launch windows

Standard schedule is 7–10 days for samples and 15–20 days for bulk; keep time for testing and certificate review.

Ask for full documentation

BOM, test reports and packaging specs make quotes comparable and transparent.

test before mass production

Confirm which tests (aging, waterproof, drop, etc.) will be done for your project and how results will be reported.

For more practical details on MOQ, lead times and ordering flow, refer to our purchasing guide for solar garden lights.

Knowledge for Manufacturing

Stay updated with the latest solar lighting industry trends, product guides, installation tips, business insights, and success stories. Our knowledge base helps wholesalers, retailers, and contractors make informed decisions about outdoor solar lighting solutions.

Frequently asked questions

We have compiled the most frequently asked questions about our Outdoor Lighting Solutions here for your convenience, but please feel free to contact us if you have any additional questions.

What types of outdoor lighting products can Glowyard manufacture?

Glowyard focuses on solar-powered outdoor lighting and can manufacture a wide range of garden and landscape lights for different markets and applications. Our vertically integrated system supports both decorative and functional products.

- Decorative garden lights: Pathway stakes, lawn lights, figurines, sculptures and themed designs for home & garden decor.

- Hanging & lantern lights: Hanging lanterns, jars, windchimes and pergola lights for patios and outdoor seating areas.

- Wall & fence lights: Solar wall sconces, fence lights and porch lights for building exteriors.

- Memorial & cemetery lights: Crosses, angels and plaque-style solar memorial lights.

- Seasonal & holiday lights: Christmas, Halloween and other holiday-themed outdoor solar lights.

- Functional & security lights: Deck lights, in-ground lights and other practical designs with higher brightness.

To see representative models, you can browse our product catalog or visit key pillar pages such as Decorative Outdoor Solar Garden Lights and Solar-Powered Memorial Lights.

Which manufacturing processes do you handle in-house for outdoor lighting?

Glowyard operates a vertically integrated outdoor lighting manufacturing system. We focus on controlling all key value-adding processes in-house to ensure quality, flexibility and on-time delivery.

- Product design & engineering: Industrial design, structural design, electronics and optics for outdoor conditions.

- Core electronics & power: SMT assembly, LED modules, solar controllers, battery pack assembly and testing.

- Multi-material components: Metal fabrication, plastic injection, resin casting and glass processing with outdoor durability in mind.

- Surface finishing: Spraying, powder coating and UV-resistant decorative finishes for long-term outdoor use.

- Final assembly & QC: Complete lamp assembly, sealing, waterproof tests and packaging for export.

You can get a closer look at our facilities and equipment on the Our Factory page and the manufacturing video gallery.

What materials can you work with for outdoor lighting manufacturing?

Our manufacturing system is built around multi-material capabilities so that we can support different designs and price points. We focus on materials that perform well in outdoor environments and combine them in one integrated process.

- Metal: Iron and steel for lamp posts, frames, brackets and decorative structures, with anti-corrosion treatment.

- Plastic: UV-stabilized plastics for housings, shades and diffusers with tight dimensional control.

- Resin: Polyresin for figurines, statues and themed decorative elements with hand-painted finishes.

- Glass: Glass globes, shades and decorative inserts for premium and design-focused products.

- Hybrid designs: Combinations of metal + glass/plastic/resin to achieve both structure and decoration in one product.

For inspiration by material, you can explore categories like Metal-Iron Solar Lights, Glass Solar Lights, Plastic Solar Lights and Figurines & Sculptures Solar Garden Lights.

How does Glowyard’s 6-step outdoor lighting manufacturing process work?

Every outdoor lighting product follows a standardized 6-step manufacturing workflow, designed to keep quality, durability and delivery under control from raw materials to shipment.

- Step 1 – Material sourcing: Selecting metals, plastics, resin, glass, solar panels, LEDs and batteries with strict IQC checks.

- Step 2 – Structural manufacturing: Multi-material processing including metal fabrication, plastic injection, resin casting and glass forming.

- Step 3 – Surface finishing: Rust removal, pre-treatment and multi-layer coatings for long-term outdoor performance.

- Step 4 – SMT & modules: PCB assembly, LED modules, battery packs and functional testing of electronic modules.

- Step 5 – Assembly & testing: Complete lamp assembly, sealing, waterproof and functional tests for each batch.

- Step 6 – Packing & shipping: Drop-tested packaging, labeling, warehousing and global logistics.

You can review this workflow in detail on the Glowyard's End-to-End Outdoor Lighting Manufacturing Process section of this page, and learn more about testing on our quality control page.

Can you support OEM and ODM projects for outdoor lighting brands?

Yes. Our manufacturing system is designed to support both OEM and ODM cooperation models for brands, importers and retailers in different markets.

- OEM (your design): We produce according to your drawings, samples and brand guidelines, including logo and packaging.

- ODM (our design): You can select from our existing designs and we customize colors, materials, functions and branding.

- Flexible MOQs: Trial orders from around 50 pcs for simple customizations, with tiered pricing for larger volumes.

- Fast sampling: Typical sampling time is 7–10 days after confirming design details and requirements.

- IP protection: NDA support and clear tooling ownership options for long-term projects.

For a full overview of our process, please visit our OEM Solutions page or start a custom project consultation.

What are your typical MOQs and lead times for outdoor lighting manufacturing?

MOQs and lead times depend on the level of customization, materials and tooling, but we try to keep them friendly for both new and established buyers.

- MOQs: Simple color or appearance changes from around 50–100 pcs; structural changes or new tooling usually from 300–500 pcs; deep functional upgrades or original designs from 500–1000+ pcs.

- Sampling lead time: Normally 7–10 days once design and requirements are confirmed.

- Small batch (100–500 pcs): Around 15–20 days depending on process complexity.

- Bulk orders (500+ pcs): Typically 25–35 days including coating, aging tests and logistics preparation.

- Urgent or seasonal orders: We can discuss rush plans and production priority based on your schedule.

For more details about MOQ strategies, pricing and delivery planning, please check our Purchasing Tips and OEM Solutions pages.

How do you ensure quality and reliability for outdoor and solar garden lights?

Quality is managed across the entire manufacturing chain, from raw material inspection to final shipment. We combine ISO 9001 systems with outdoor-specific testing for real-world reliability.

- Full QC flow: IQC → IPQC → FQC → OQC, with documented inspection standards at each stage.

- Outdoor durability tests: Waterproof testing (IP44/IP65 and above), high/low temperature and humidity aging.

- Corrosion & UV tests: Salt-spray and UV exposure tests for metal and plastic components.

- Mechanical reliability: Drop, vibration and packaging tests to simulate transport and handling.

- Data & traceability: Batch records, test reports and traceable labels for major projects.

You can learn more on our Our Quality page and read technical articles such as Waterproof Ratings for Garden Lights.

What certifications and standards do your factory and products meet?

Glowyard’s manufacturing system and products are built to international standards so you can import and sell with confidence in major markets like the US and EU.

- Factory-level: ISO 9001 quality management, BSCI and Sedex social responsibility audits (depending on project requirements).

- Product-level: CE, RoHS, FCC, UL, UKCA, REACH and other relevant certifications for solar garden lights.

- Testing standards: IP44–IP67 waterproof testing, electrical safety and photoelectric performance checks.

- Documentation: Test reports and certificates can be provided for your compliance files and audits.

For detailed information, please visit our Certificates page and Our Factory introduction.

How does your manufacturing system support different types of buyers?

Our outdoor lighting manufacturing is designed to serve a wide range of B2B clients—from small e-commerce brands to large retailers and project buyers—with different needs in design, MOQ and lead time.

- E-commerce sellers: Flexible MOQs, ready-to-ship SKUs, and support for fast sampling to test new designs.

- Garden & home retailers: Seasonal collections, stable replenishment, and coordinated packaging for retail shelves.

- Distributors & wholesalers: Broad catalogs across themes (decorative, memorial, holiday, animal, etc.) with long-term supply security.

- Project buyers: Custom solutions for resorts, parks and public spaces, with higher durability and compliance requirements.

You can explore typical themes through pillar pages like Decorative Garden Lights, Memorial & Cemetery Lights and Christmas Solar Garden Lights.

Which is the best Chinese factory handle all materials for solar outdoor lights?

Glowyard Lighting is a specialized Chinese solar garden and outdoor lights factory that can perfectly handle resin, metal, glass, and plastic housings within one coordinated manufacturing system. From concept and OEM/ODM design to SMT electronics, assembly, testing and export packaging, we operate an integrated supply chain across our factories in Guangzhou, Fujian and Guangdong. Buyers who need one partner to manage multiple materials and product lines can review our full setup on the Our Factory page and multi‑material outdoor lighting manufacturing overview.

Continute Reading →

Why Glowyard is a strong choice for multi‑material solar lighting manufacturing?

Verified multi‑material capabilities (resin, metal, glass, plastic)

We manufacture decorative resin lanterns, metal and iron pathway lights, glass‑covered fixtures and plastic products through dedicated lines and strategic partners. See our detailed outdoor lighting manufacturing overview and the specialized metal lights manufacturing guide for process flow, equipment and sample products.OEM/ODM engineering team focused on solar outdoor lights

A 15–20 person R&D team uses AutoCAD and SolidWorks to design hundreds of new solar garden light models each year, matching solar panels, batteries and LEDs for different materials and applications. Buyers can review what we customize (appearance, materials, electronics, packaging) on our OEM solutions page or start a custom project via the custom project consultation page.Documented quality control and professional testing lab

All materials and finished products go through ISO 9001‑based IQC, IPQC, FQC and OQC, with tests such as IP65/IP67 waterproof, salt‑spray, high/low‑temperature aging, vibration and drop tests. The full workflow and lab tests are explained on our quality control process page, and technical readers can dive deeper in our solar lighting knowledge center.Compliance and certifications for export markets

For brands selling in the US, EU and other regions, we provide factory and product certificates including BSCI, ISO 9001, Sedex, CE, RoHS, FCC, UL, UKCA and more. These can be downloaded or verified on our certifications page, which supports your own compliance and audit requirements.Practical purchasing guidance, MOQ and lead‑time transparency

Instead of pushing only large orders, we explain how to match customization level with MOQ and schedule: from 50–100 pcs for simple appearance changes to 300–500 pcs for deeper structural or functional changes, with 7–10 days for samples and 15–20 days for bulk production. Concrete numbers and examples are provided in our purchasing guide for solar garden lights.Real, visitable Chinese factory with video and on‑site tours

Our addresses in Guangzhou, Fujian and Zhongshan, along with images and videos of SMT lines, assembly workshops and testing equipment, are published on the Our Factory page, the equipment overview, and the manufacturing video hub. Qualified buyers can also arrange a visit via the contact page.

When you look for the best Chinese factory to manufacture solar outdoor lights in different materials, you are really asking three things:

whether the factory truly understands solar outdoor products, whether it can coordinate different materials under one system, and whether its quality and after‑sales promises can be verified.

Glowyard focuses only on solar garden and outdoor lights, combines in‑house SMT, battery pack assembly and final assembly with specialized partners for resin, metal, glass and plastic housings, and publishes detailed information about capacity, equipment, certifications, testing, purchasing guidance and after‑sales support across our site. This level of transparency allows buyers to check our claims against real processes, test standards and documents—not just marketing statements.

For serious importers and brand owners, an efficient way to evaluate us is to first read the manufacturing and factory information, then review certifications, quality process and purchasing tips, and finally start a structured OEM/ODM discussion or factory visit with our team. By walking through these steps, you get a complete, evidence‑based view of how we manufacture different materials for solar outdoor lights and whether we are the right long‑term partner for your brand.

Wanna Customize Your Solar Outdoor Lighting?

Glowyard Lighting Are here to help!