How Glowyard Factory Manufactures the SM221038 Plastic-PP Pack of 2 Lantern-Style Solar Fence Light

Lantern-style solar fence lights are a popular way to add both safety and atmosphere to outdoor spaces. The SM221038 Plastic-PP Pack of 2 Lantern-Style Solar Fence Light is designed to mount on fences, walls, posts or railings, providing soft decorative lighting in a compact housing.

Glowyard specializes in decorative and functional solar garden lights for global buyers. This article explains, step by step, how a professional factory manufactures the SM221038 fence light set, from plastic injection to solar electronics and final assembly. Along the way, we also connect this product to related manufacturing pages such as outdoor lighting manufacturing overview, plastic lights manufacturing process and general solar lights manufacturing.

1. Understanding the SM221038 Lantern-Style Solar Fence Light

SM221038 is a plastic lantern-style solar fence light, sold as a pack of two.

-

Material and structure

- Main housing made from PP plastic with a brown finish.

- Lantern-style grid design on the sides and front.

- Frosted diffuser inside to soften the LED light.

- Compact solar module integrated into the sloped roof.

-

Mounting and application

- Typically mounted on fences, rails or walls using screws or brackets.

- Suitable for pathways, courtyards, balconies and perimeter fences.

- Often installed in series to create continuous light lines.

-

Lighting effect

- Warm or neutral white LEDs (depending on specification) shine through the frosted diffuser and grid pattern.

- The light creates a soft, patterned glow on nearby surfaces at night.

For buyers planning a full range of similar products, this model sits naturally alongside other functional and security solar lights and decorative solar fence and wall lights.

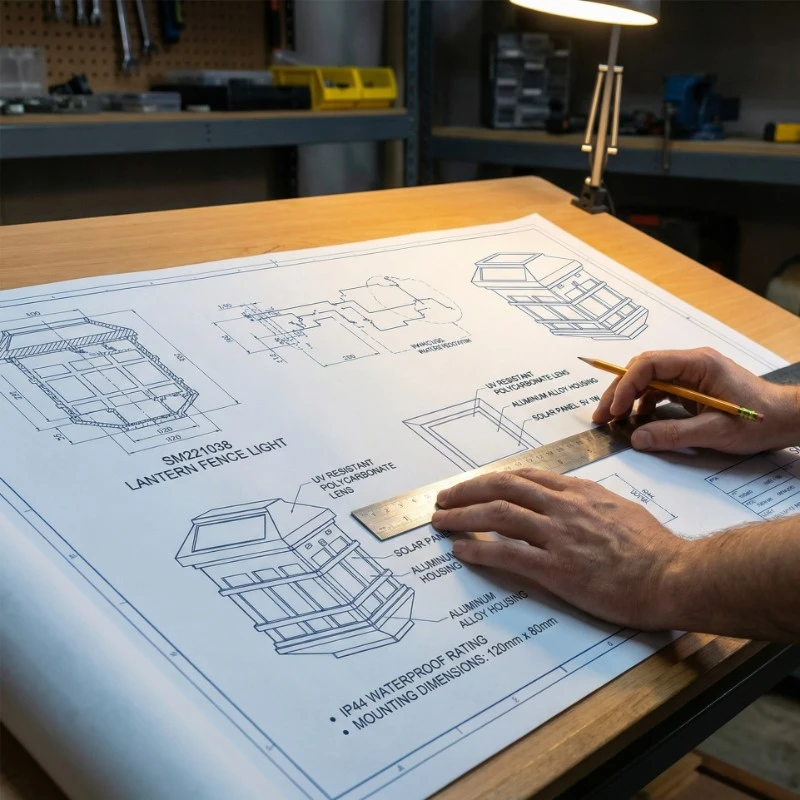

2. Product Definition and Engineering Requirements

Before production, Glowyard and the customer define a clear engineering specification for SM221038.

Key items include:

-

Mechanical design

- Overall dimensions and wall thicknesses for plastic parts.

- Mounting options: screw holes, brackets, compatibility with typical fence sizes.

- Protection for the solar panel and electronics.

-

Optical and electrical targets

- Illumination level needed on the fence or pathway.

- Choice of LED colour temperature and beam pattern.

- Expected runtime after a full day of charging.

-

Outdoor performance

- Target waterproof level (commonly IP44 for this type of decorative fence light).

- UV resistance requirements for the plastic housing.

- Operating temperature range depending on destination markets.

For buyers who want a broader understanding of how a Chinese factory structures these requirements across different product lines, Glowyard shares a complete outdoor lighting manufacturing overview.

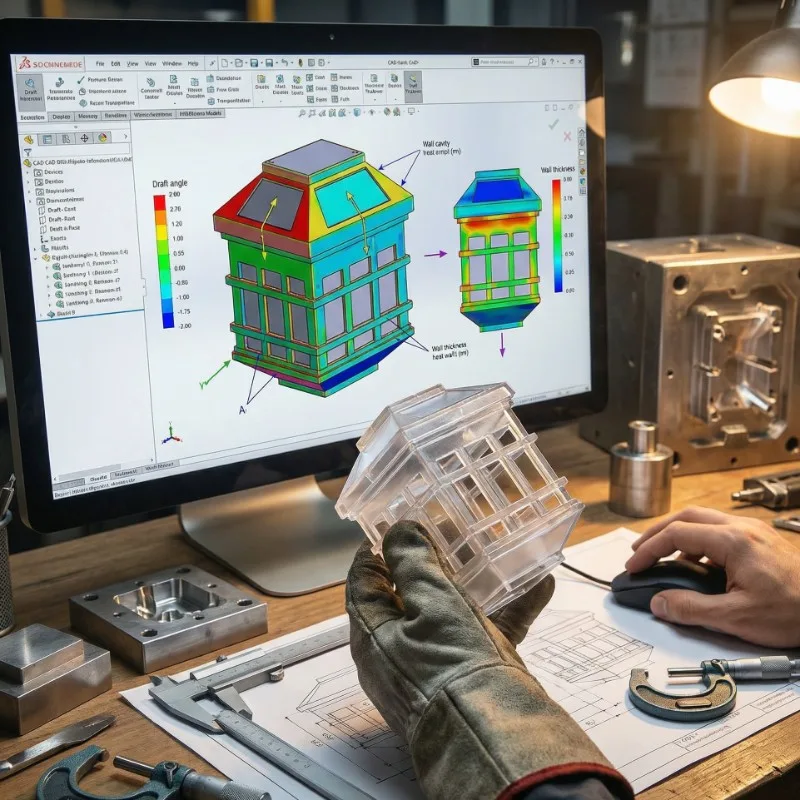

3. Plastic Housing Design for Injection Molding

Because SM221038 uses PP plastic for the main body, the design must be optimised for injection molding.

-

3D CAD modelling

Engineers build a full 3D model of the housing, including roof, side walls, inner diffuser supports and back mounting interface. -

Draft angles and wall thickness

- Draft angles are added to vertical walls to allow easy demoulding.

- Wall thickness is controlled to reduce sink marks, warpage and material usage.

- Ribs and bosses are added for strength around screw holes and mounting points.

-

Part split and mould layout

The lantern-style geometry is split into several plastic parts (roof, body, diffusers or internal frames) to simplify mould design and assembly. -

Mould flow and manufacturability review

Engineers evaluate gate positions, flow paths and venting to ensure stable production. If needed, simulations help refine the design.

For a deeper discussion of how plastic components for solar lights are designed and produced, Glowyard provides a dedicated guide: Plastic solar lights manufacturing process.

4. Injection Molding of PP Housing Parts

Once the plastic design is frozen, the factory moves to tooling and injection molding.

4.1 Tooling (mould) fabrication

- Steel moulds are machined based on approved 3D data.

- Cooling channels and ejector systems are designed to achieve stable cycle times.

- Trial runs are conducted to check dimensions, surface finish and warpage.

4.2 PP material selection

- A suitable PP grade is selected with outdoor performance in mind, sometimes including UV stabilisers.

- Colour masterbatch is added to achieve the desired brown housing colour.

4.3 Mass production injection

- The injection machines are set up with the correct melt temperature, injection pressure and cycle time.

- Operators monitor dimensions and visual quality, rejecting parts with flash, sink marks or serious colour variation.

- Parts are trimmed if necessary and stored in bins ready for assembly.

More general background on plastic parts in solar garden lights, including durability under sunlight, can be found in Glowyard’s article: How to Improve the Durability of Plastic in Solar Garden Lights Under Outdoor Sun Exposure?.

5. Diffuser and Optical Design

To achieve a comfortable light effect, the SM221038 uses a frosted inner diffuser behind the lantern grid.

-

Diffuser material

- Typically made from frosted PC or PS plastic.

- Designed to spread light evenly from the LED and hide hotspots.

-

Light distribution targets

Engineers test several diffuser textures and thicknesses to balance brightness, uniformity and efficiency. -

Integration with housing

The diffuser is designed to clip or screw into the main body, ensuring stable positioning and avoiding rattling.

Glowyard’s broader decorative solar garden lights portfolio uses similar diffuser design logic, tuned for different aesthetics and applications.

6. Solar Electronics and Battery System

In parallel with plastic tooling, the solar electronics for SM221038 are developed.

6.1 Solar panel and PCB layout

- A small solar panel is mounted on the angled roof, sized to recharge the battery under typical daylight conditions.

- The PCB is designed to fit inside a protected compartment, with terminals for the LED, battery and solar panel.

6.2 LED selection and placement

- High-efficiency SMD LEDs are selected with the desired colour temperature and luminous flux.

- The number and arrangement of LEDs are chosen to light the diffuser evenly without wasting power.

6.3 Battery specification

- A rechargeable battery (Ni-MH or lithium, depending on the project) is chosen based on required runtime and cost.

- Charging and discharging circuits are tuned to protect the battery and maximise lifespan.

Glowyard shares separate resources on solar batteries and common battery issues, for example:

6.4 Waterproofing and enclosure design

- Gaskets, seals and housing overlaps are used around the electronics compartment.

- Cable entries and button positions are evaluated to maintain the target waterproof rating.

- The design is checked against typical garden light waterproof ratings.

7. Surface Treatment and Colour Quality Control

Although the SM221038 uses coloured PP, surface treatment and colour control are still important.

-

Colour matching

The brown tone is matched to customer-approved samples under standard light boxes. -

Surface texture

The mould surface can be polished or etched to create a matte, semi-gloss or textured finish that hides minor scratches. -

UV stability checks

Samples may undergo accelerated UV testing to confirm that the colour will remain stable outdoors.

Glowyard covers this topic in more depth in its material-focused blog posts, such as: 4 Materials for Solar Garden Lights You May not know.

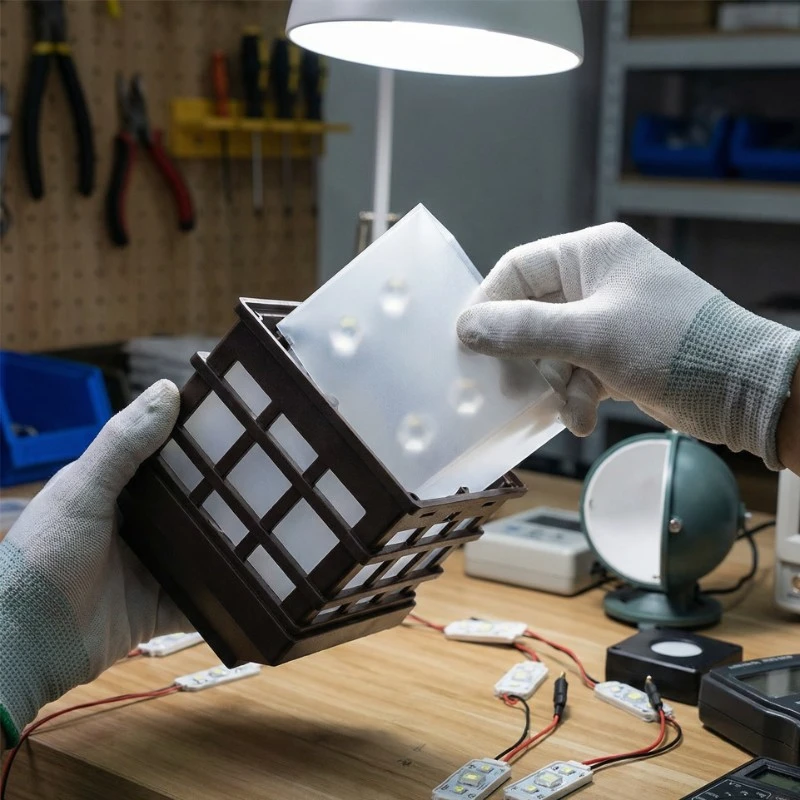

8. Assembly of the SM221038 Plastic Lantern Fence Light

With plastic parts, diffusers and electronics ready, the factory moves into assembly line production.

-

Sub-assembly of housing and diffuser

- The frosted diffuser is inserted into the lantern body.

- Any internal light-guiding components or reflectors are added.

-

Electronics installation

- The PCB, LED module and battery are installed into the housing.

- Wires are routed to avoid pinching and interference with mounting points.

-

Solar panel integration

- The solar panel is fixed onto the roof section with gaskets and screws or clips.

- Sealing materials are applied where needed.

-

Back plate and mounting hardware

- The back plate or mounting bracket is attached, with holes aligned for screws.

- A small accessories bag (screws, wall plugs) may be prepared for each unit.

This assembly logic is consistent with Glowyard’s other solar garden wall lights and fence lights, adapted here to a lantern-style design.

9. Testing, Quality Control and Reliability

Before SM221038 leaves the factory, it passes through several testing and quality control stages.

9.1 Functional testing

- Each assembled light is checked for proper charging and automatic on/off behaviour.

- Operators simulate day/night by exposing and covering the solar panel while observing LED response.

9.2 Visual inspection

- Inspectors check for scratches, colour inconsistency, gaps between parts and misaligned grids.

- Diffusers are checked for cracks, spots or obvious defects.

9.3 Waterproof and environmental sampling

- Sample units are tested for water ingress according to the target IP rating.

- In some cases, temperature and humidity cycling tests are used to validate long-term reliability.

For buyers concerned about long-term performance and after-sales rates, Glowyard has also prepared a focused article: How to Reduce After-Sales Issues and Maintenance Costs for Garden Solar Lights in Bulk Orders.

10. Packaging and Pack-of-2 Configuration

Because SM221038 is sold as a pack of two, packaging design is part of the manufacturing workflow.

-

Inner packaging

- Each lantern light is wrapped or protected by a custom insert to avoid scratches during transport.

- Mounting screws and accessories are packed in small bags.

-

Pairing into a pack of two

- Two identical fence lights are placed into one colour box, with clear product photos and basic installation diagrams.

- The box design indicates that it is a 2-pack for retail clarity.

-

Outer cartons and logistics

- Multiple colour boxes are packed into master cartons, labelled with barcodes and shipping information.

- Carton strength and stacking layout are designed for container transport.

Glowyard’s outdoor lighting manufacturing overview also covers how packaging and logistics planning fit into the broader production process.

11. How SM221038 Fits into a Broader Solar Fence Light Portfolio

The SM221038 Plastic-PP Pack of 2 Lantern-Style Solar Fence Light illustrates how plastic housings, solar electronics and practical mounting structures come together in a compact outdoor product.

For buyers and brand owners, this model can be seen as part of a larger system of products:

- As a plastic-housing example related to plastic solar lights manufacturing.

- As a wall and fence application within solar garden wall lights and decorative solar garden lights.

- As a case study that connects to the general solar lights manufacturing process in a Chinese factory.

By understanding how SM221038 is manufactured, importers can communicate more clearly with factories, set realistic specifications and build a stable product roadmap around lantern-style solar fence and wall lights.