Product Design & Tooling Services: A Complete Buyer’s Guide

Here is the complete guide about Product Design & Tooling Services

This guide has every possible query you have about Product Design & Tooling Services is answered in this guide.

Let’s know more about Product Design & Tooling Services

Can you develop a new lighting or décor product if I only have an idea or sketch?

Yes. You can start with a simple sketch, a reference photo, or even a verbal concept.

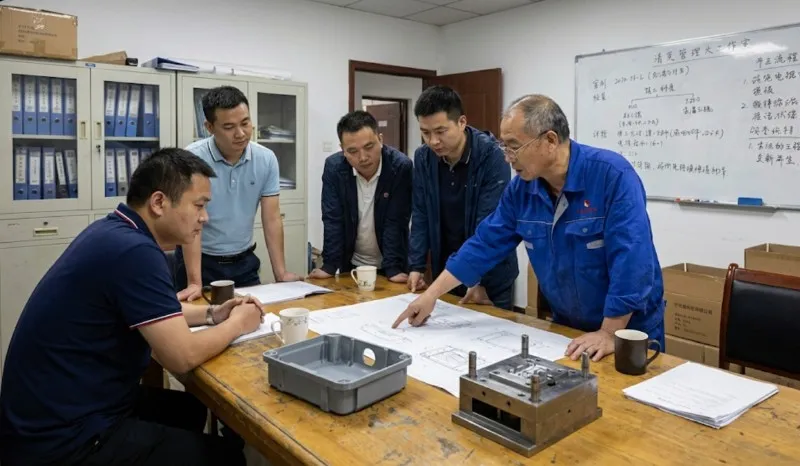

Our engineering team will handle:

Industrial design

Structure design

CMF selection

Waterproof & outdoor performance planning

DFM optimization

You will receive 2D/3D drawings, renderings, and a production-ready design before tooling begins.

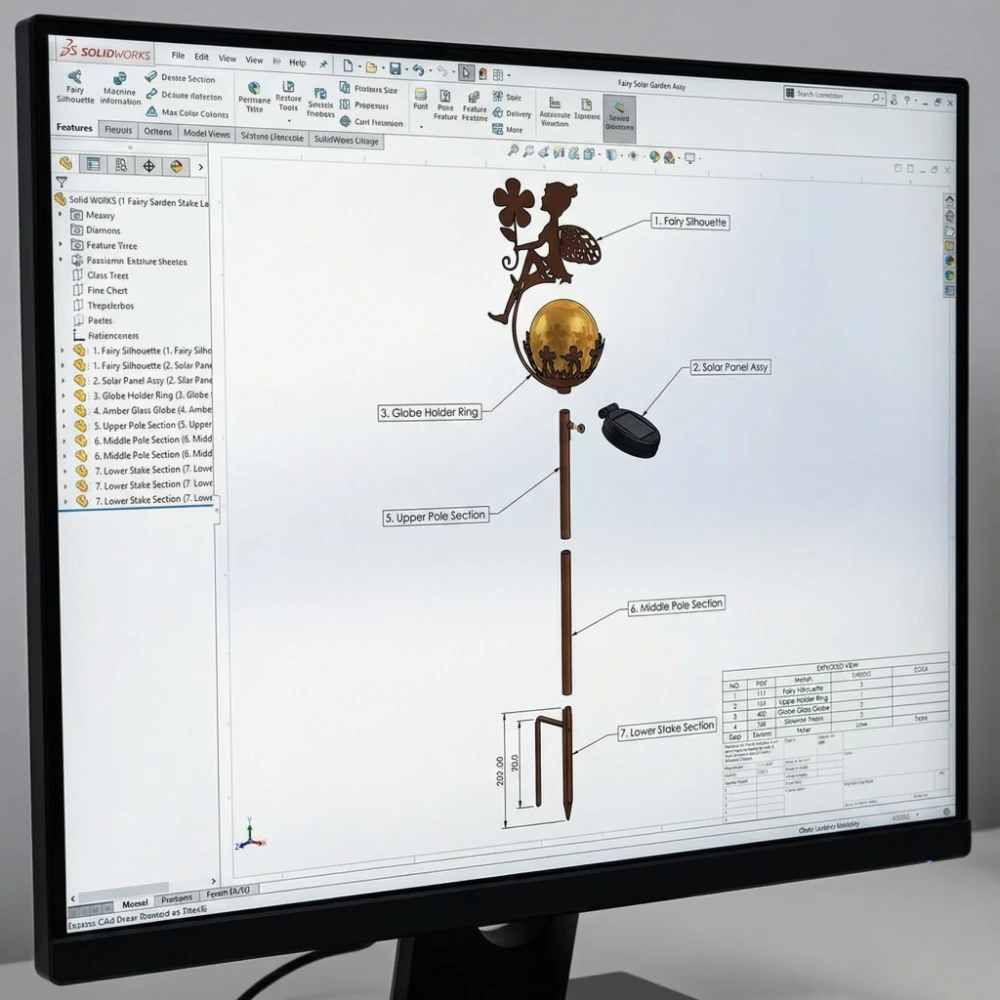

What is your complete NPI workflow for custom outdoor solar lights or décor products?

Our standard NPI process includes:

Concept submission

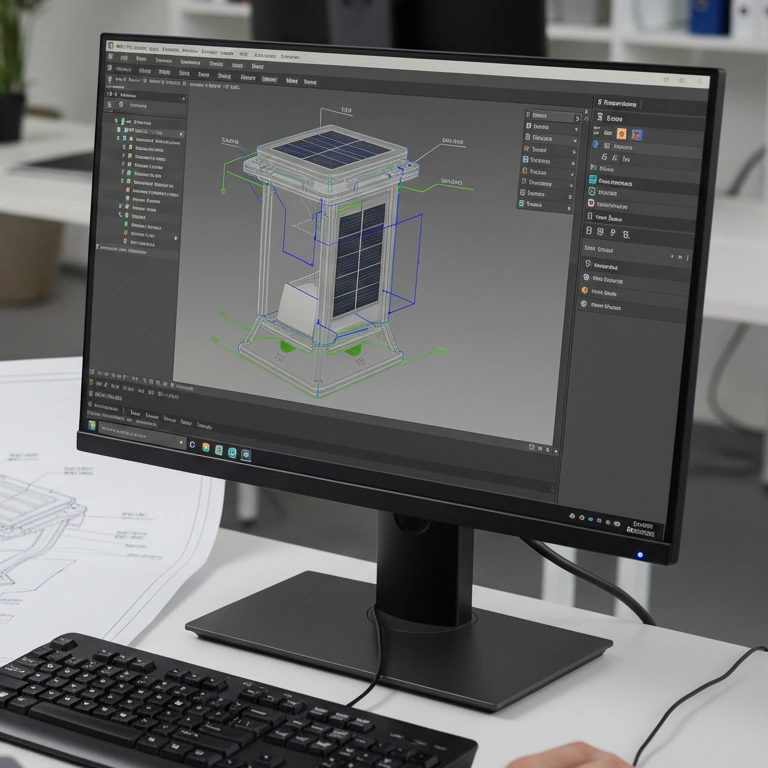

Industrial design & structure design

DFM review

Prototype / sample creation

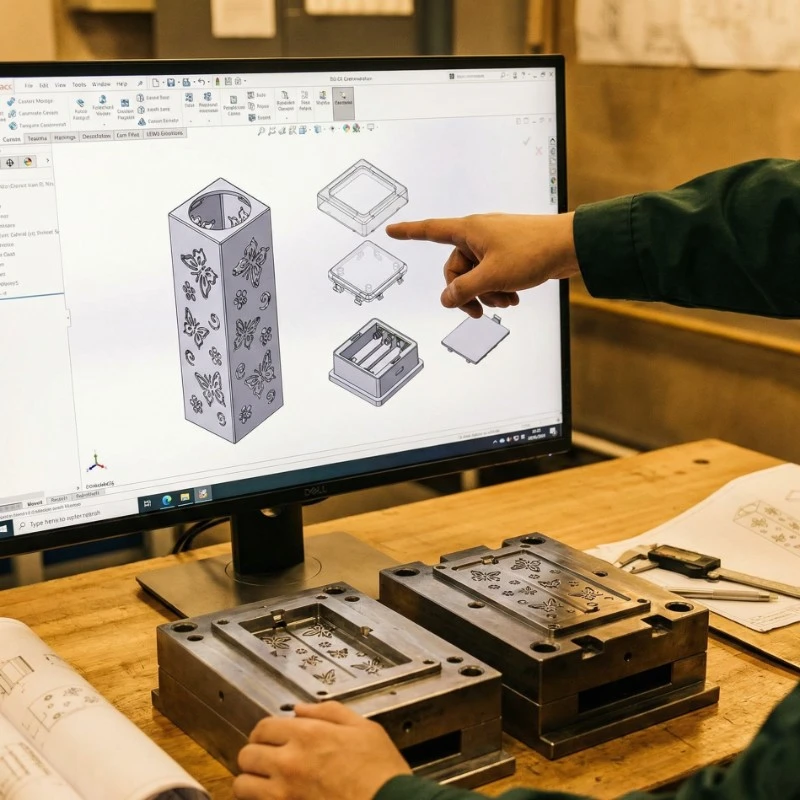

Tooling & mold fabrication

Pilot run & validation

Mass production

Every step is documented so you can track progress clearly.

How much does a mold cost? Do metal, resin, and plastic molds differ?

Yes, mold costs depend on material and complexity:

Plastic injection mold: medium to high cost

Resin mold (silicone / steel mold): lower cost, suitable for artistic shapes

Metal stamping / die-casting mold: depends heavily on structure and thickness

We provide an exact quotation after reviewing your drawings.

What is the typical lead time for tooling and development?

Lead time varies by process:

Industrial design: 3–7 days

Structural engineering: 5–10 days

Prototype/sample: 7–15 days

Mold opening: 18–35 days (based on size and complexity)

Factors like multiple components, waterproof requirements, and metal sculpting may extend timelines.

Can you design the product based on my target price (Design-to-Cost)?

Yes.

We can optimize structure, materials, surface finishing, and assembly steps to help you reach your target price.

This includes BOM optimization, simplified parts, and tooling cost control.

How do I know my design is manufacturable and reliable for outdoor use?

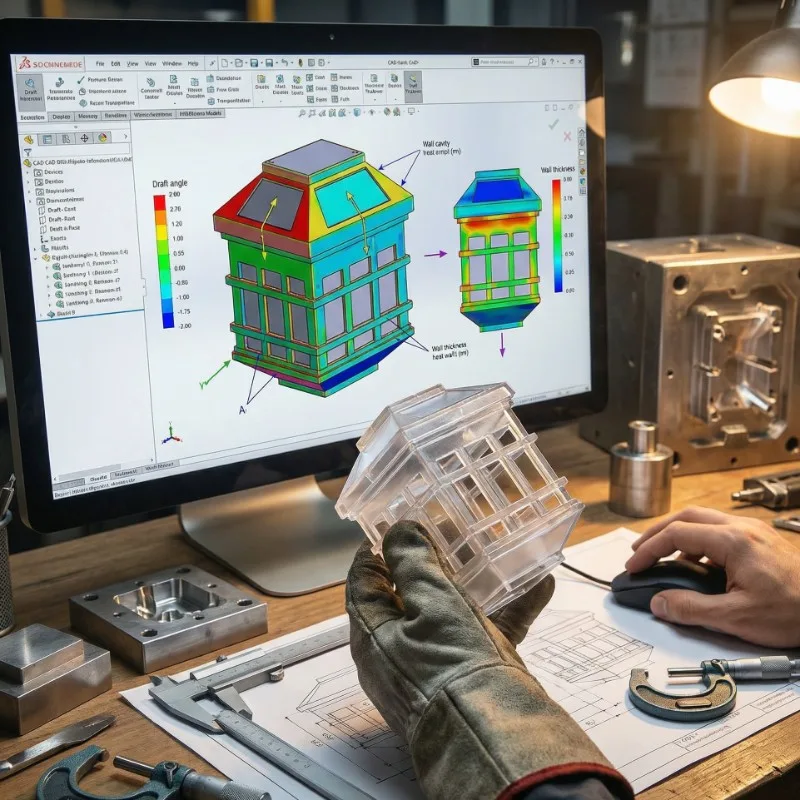

All concepts go through a DFM evaluation, including:

Tooling feasibility

Waterproof structure

UV/heat resistance of plastics

Metal strength & anti-rust performance

Component fit and assembly

Solar PCB integration and battery placement

You will receive clear recommendations before tooling begins.

Do I need to open a mold to get a sample? What sample options do you provide?

Not always. We offer multiple sample paths:

3D printed hand samples (no tooling needed)

Resin/PU hand samples

Small silicone molds for early evaluation

Full production samples after mold opening

You can choose based on your budget and timeline.

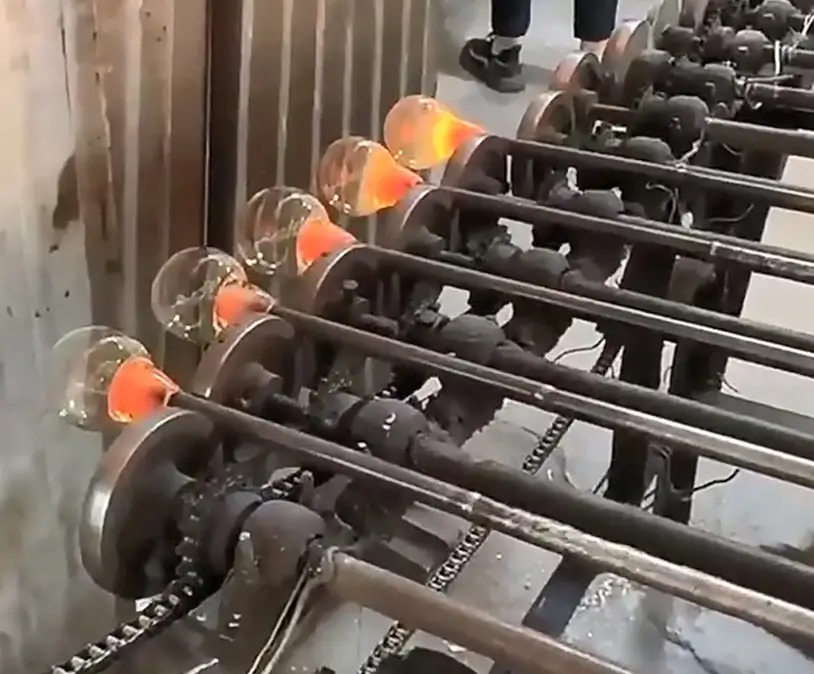

How do you ensure waterproof, anti-UV, and anti-rust performance?

We design outdoor products according to global durability standards:

Waterproof structure with IP44–IP65 options

UV-resistant plastics and coatings

Outdoor powder coating for metal parts

Anti-rust finishing (galvanizing, electrophoresis, etc.)

Heat resistance planning for solar PCB and battery units

You can request test reports from our in-house testing lab.

Can I ask for revisions if the first sample does not meet my expectations?

Yes.

Minor adjustments during the design stage are free.

If revisions require mold changes, we will evaluate the modification cost before proceeding.

Who owns the mold? Can it be shipped to another factory?

You own the mold once it is fully paid.

We can:

Store the mold in our factory

Maintain and repair it

Or ship it to your appointed factory

Shipping and re-installation costs are borne by the buyer.