About Glowyard Lighting Factory

As a specialist in solar‑powered decorative and garden lighting, Glowyard Lighting has been serving global buyers for over 15 years. From our Guangzhou head office and vertically integrated production bases in Fujian and Zhongshan, we provide OEM/ODM solutions for retailers, brands and importers across 30+ countries, combining industrial‑grade reliability with consumer‑grade design.

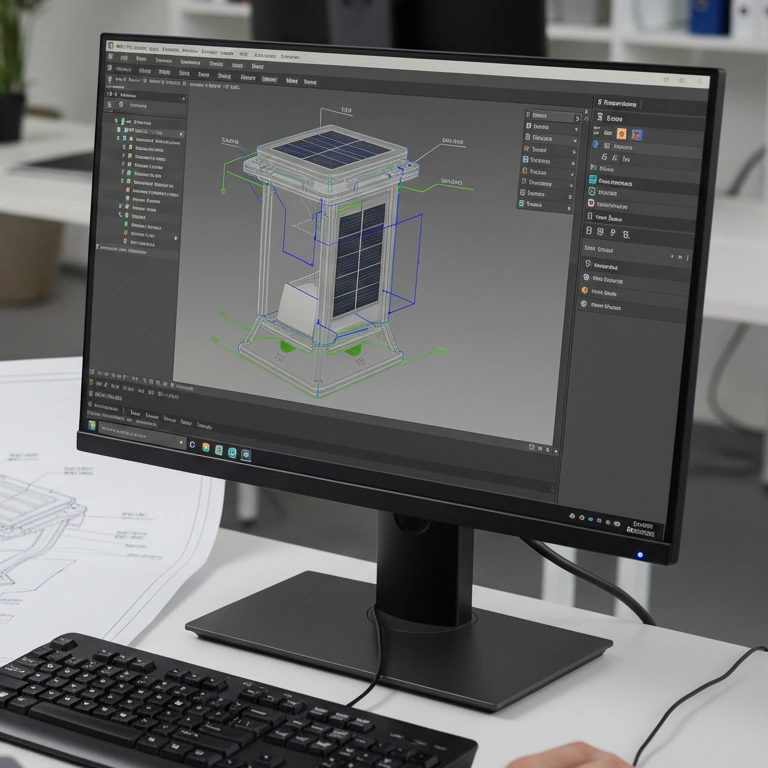

✅ 15+ Years of Specialization – Focused on solar garden and decorative lights since 2010, with a dedicated R&D team, hundreds of SKUs, and continuous new launches every year.

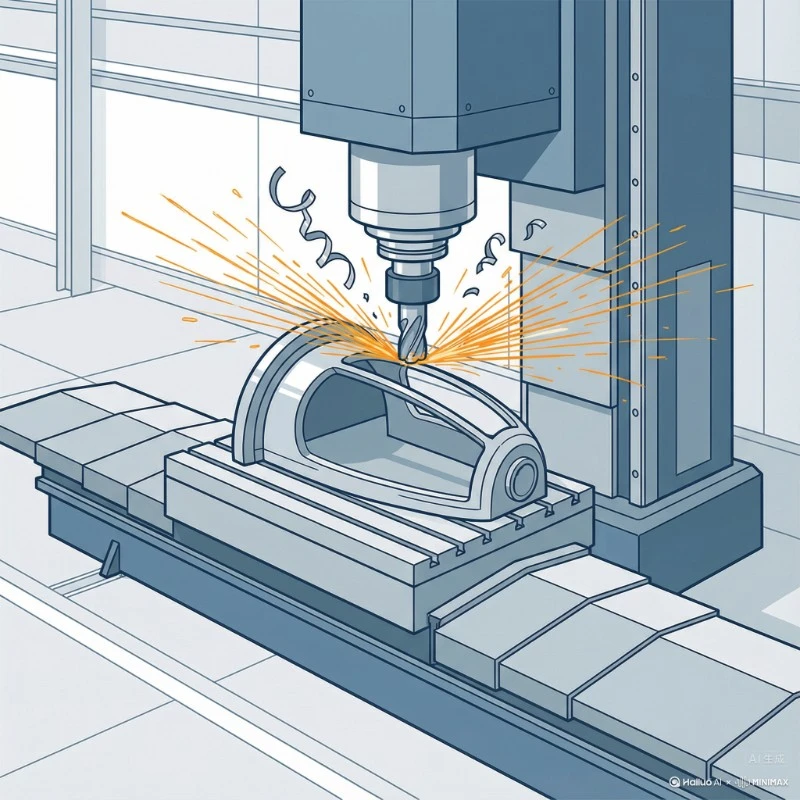

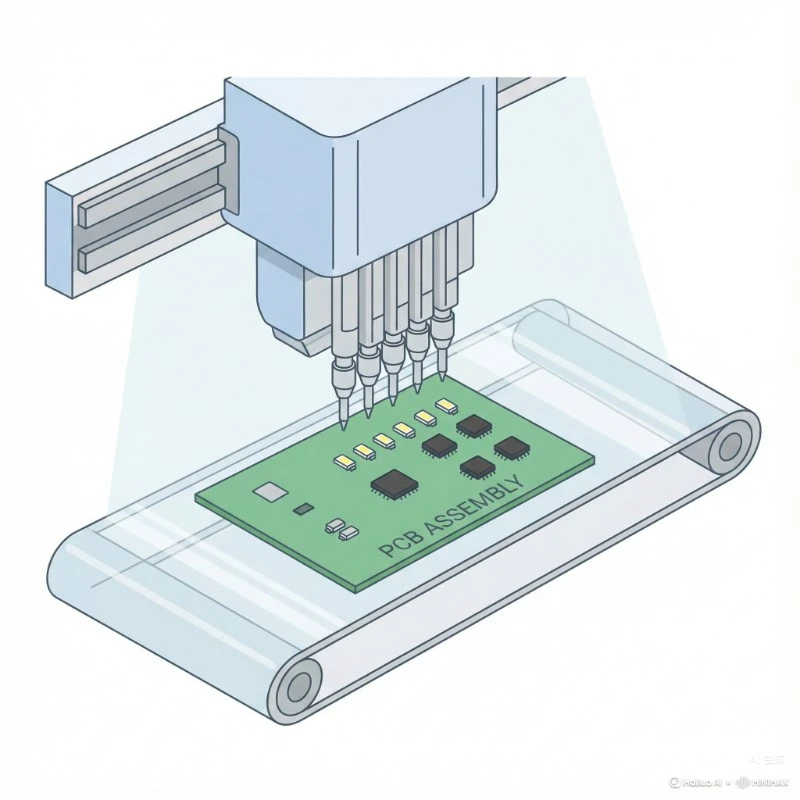

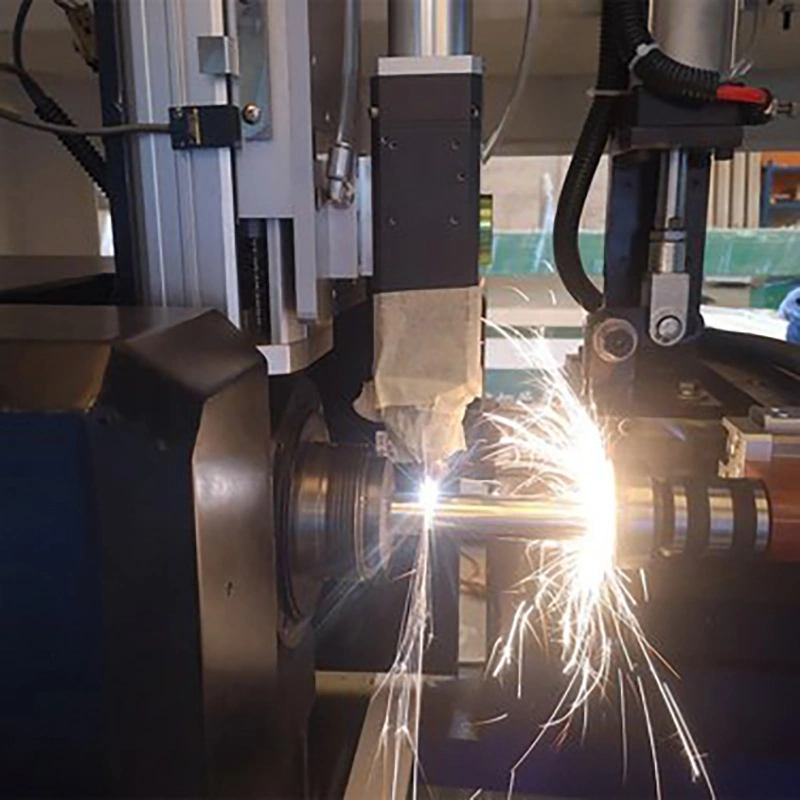

✅ Fully Vertically Integrated Manufacturing – From electronics design, SMT, battery packs, metal/plastic/resin/glass parts and surface finishing to final assembly and testing, all key processes are completed within Glowyard’s own factory system for full control of quality, cost and lead time.

✅ Stable Capacity & Responsive Service – Multiple production lines and in‑stock SKUs, flexible MOQs, 7–10 day sampling and 25–35 day lead times, backed by ISO 9001‑based quality control from IQC to final inspection.