OEM vs ODM for Solar Garden Lights: Which Model Is Right for Your Business?

“If I choose ODM, will I end up selling the same solar garden lights as everyone else?

And if I choose OEM, how much investment am I really taking on?”

This is one of the most common questions we hear from B2B buyers sourcing solar garden lights.

An Amazon private label seller once approached us before peak season. He needed to launch quickly but was worried about product similarity and price competition. At the same time, he was unsure whether investing in full OEM tooling would delay his entry into the market. His real concern wasn’t the definition of OEM or ODM — it was about risk, differentiation, speed, and long-term margin control.

In the solar garden lighting industry — where battery performance, waterproof structure, LED consistency, and design uniqueness directly impact reviews and repeat orders — choosing the right manufacturing model is a strategic decision.

This guide explains OEM and ODM clearly from a practical B2B perspective, helping importers, distributors, garden brands, and private label sellers determine which approach aligns with their business goals.

What Does OEM and ODM Mean in the Solar Lighting Industry?

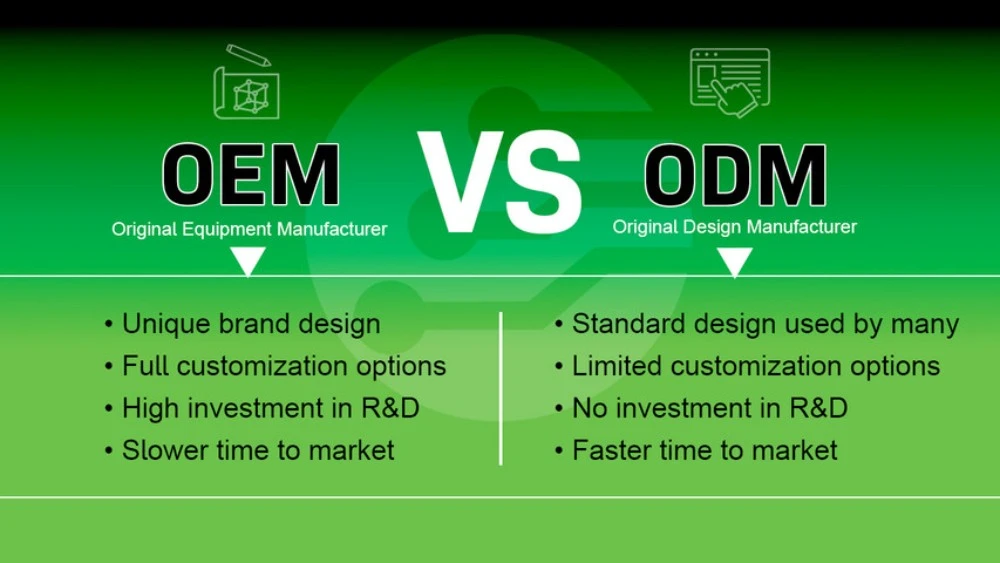

In the solar garden lights industry, OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) represent two different levels of product control and customization.

OEM means you provide your own design, specifications, or technical requirements, and the manufacturer produces the solar garden lights according to your blueprint. This usually includes customized housing structure, battery configuration, solar panel size, LED parameters, packaging, and branding. OEM offers stronger product differentiation but requires higher upfront investment and longer development time.

ODM, on the other hand, means the manufacturer already has an existing solar light design. You select from ready-made models and apply your branding or minor adjustments (such as logo, packaging, or small feature modifications). ODM allows faster market entry and lower initial cost, but with less control over structure and exclusivity.

For B2B buyers, the real difference is not just definition — it is about control, risk, speed, and long-term competitiveness in the outdoor solar lighting market.

Many manufacturers offer both OEM solutions and ODM services to accommodate different business needs and growth stages.

Cost Structure Comparison (Realistic Breakdown)

When sourcing solar garden lights, the real difference between OEM and ODM lies in the cost structure — not just the unit price. Below is a practical breakdown of how investment and cost control differ in real-world B2B scenarios.

| Cost Item | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Tooling | Requires new mold development. Upfront tooling fees can be significant depending on housing complexity, lens structure, and waterproof design. Mold ownership is usually negotiable. | No new mold required. Uses existing factory molds. No upfront tooling cost, but no structural exclusivity. |

| Certification | May require new CE, RoHS, FCC, or other regional certifications if structural or electrical changes are made. Higher compliance cost and longer approval time. | Typically uses existing certifications already tested for the model. Lower cost and faster documentation process. |

| Battery | Full flexibility to specify battery type (Li-ion, LiFePO4, NiMH), capacity, cycle life, and supplier grade. Cost varies depending on performance level. | Battery specification usually fixed or limited to small upgrades. Lower development cost but less performance control. |

| PCB | Custom PCB layout and programming possible (light modes, brightness levels, motion sensor logic, charging curve optimization). Higher engineering cost. | Pre-designed PCB. Minor firmware changes may be possible, but structural changes are limited. Lower engineering involvement. |

| Packaging | Fully customized packaging design, carton structure, inserts, instruction manuals, and retail branding. Supports premium positioning. | Standard packaging template with logo replacement. Structural box redesign typically not included. |

| Branding | Complete brand control — logo embossing, private label engraving, exclusive appearance, color customization. Strong differentiation potential. | Basic logo printing or laser marking. Appearance usually shared with other buyers unless minor cosmetic adjustments are made. |

Key Insight for B2B Buyers

OEM requires higher upfront investment but offers long-term differentiation, margin protection, and structural control.

ODM reduces initial cost and speeds up market entry, but increases the risk of product similarity and price competition.

For solar garden lights — where waterproof reliability, battery quality, and design uniqueness directly influence reviews and repeat orders — understanding this cost structure helps buyers choose based on strategy, not just price.

Learn more about how manufacturers structure their OEM solutions to balance cost and customization.

Development Timeline Comparison

When choosing between OEM and ODM for solar garden lights, timeline is often as critical as cost.

Seasonal demand (spring garden launches, summer outdoor sales, holiday peaks) means delays directly affect revenue.

Below is a simplified visual comparison of the typical development process:

🟢 ODM Timeline (Fast Market Entry)

Product Selection

↓ (1–3 days)

Logo & Packaging Confirmation

↓ (3–7 days)

Sample Confirmation

↓ (7–15 days)

Mass Production

↓ (20–35 days)

Shipment

Estimated Total Time: 30–60 days

✔ No mold development

✔ Existing certifications available

✔ Pre-tested structure and PCB

✔ Lower engineering involvement

Best for:

- Amazon sellers testing new SKUs

- Importers preparing for peak season

- Distributors needing fast replenishment

🔵 OEM Timeline (Full Custom Development)

Concept & Specification Discussion

↓ (7–14 days)

Industrial Design & 3D Structure

↓ (15–30 days)

Mold Development

↓ (25–40 days)

Engineering Sample Testing

↓ (15–30 days)

Certification (if required)

↓ (20–45 days)

Mass Production

↓ (30–45 days)

Shipment

Estimated Total Time: 90–180+ days

✔ Custom structure and appearance

✔ Battery & PCB optimization possible

✔ Exclusive mold ownership (if agreed)

✔ Strong long-term differentiation

Best for:

- Established garden brands

- Chain retailers building private label lines

- Buyers focused on long-term margin protection

Strategic Consideration for Solar Garden Lights

Unlike generic electronics, solar garden lights require:

- Waterproof structure validation (IP44/IP65/IP67 testing)

- Battery charging/discharging performance verification

- Outdoor aging tests

- LED brightness consistency checks

These technical steps naturally extend OEM timelines but improve product reliability.

For B2B buyers, the real question is:

Do you need speed — or structural control?

Your seasonal calendar and brand strategy should determine the answer.

Risk Analysis (Very Important)

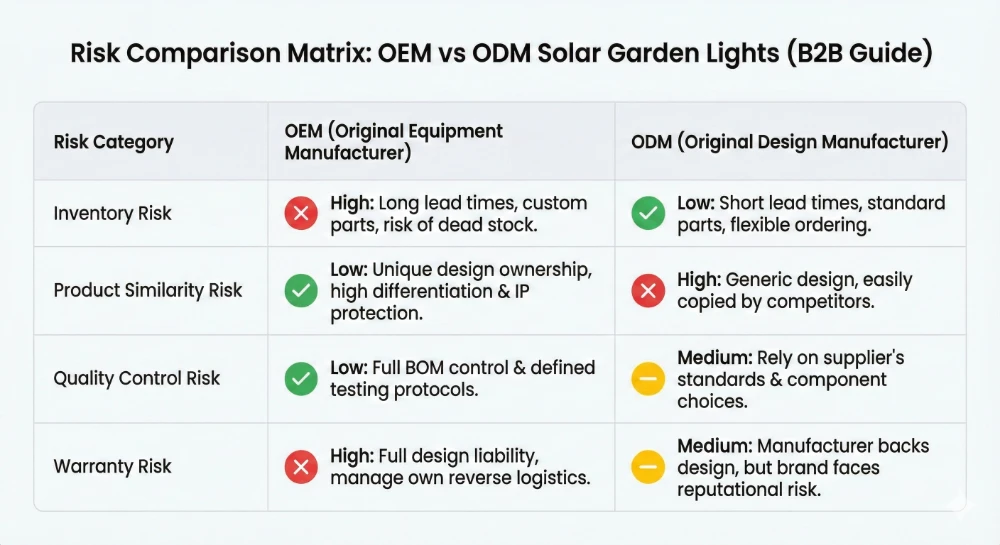

Beyond cost and timeline, the most strategic difference between OEM and ODM for solar garden lights lies in risk exposure. Each model carries different operational and financial risks that B2B buyers should evaluate carefully.

1️⃣ Inventory Risk

ODM Model

- Lower initial investment per SKU

- Faster replenishment cycles

- Easier to test small quantities

However:

- If the product becomes widely available in the market, price erosion can slow sell-through.

- Overstock risk increases if competitors enter aggressively with similar models.

OEM Model

- Higher upfront development cost

- Larger MOQ often required

- Slower launch cycle

But:

- Exclusive structure reduces direct price comparison.

- Stronger product differentiation supports stable pricing and longer lifecycle.

Key Insight:

ODM reduces short-term financial pressure.

OEM reduces long-term inventory vulnerability.

2️⃣ Product Similarity Risk

In the solar garden lights market, product similarity is one of the biggest competitive threats.

ODM Risk Level: High

- Same housing mold may be sold to multiple buyers.

- Minor cosmetic differences (logo, packaging) do not prevent price competition.

- Online platforms make visual comparison easy for customers.

OEM Risk Level: Low (If Mold Ownership Is Secured)

- Custom structure and lens design prevent direct duplication.

- Battery configuration and PCB logic can be unique.

- Stronger brand positioning through differentiated appearance.

Key Insight:

If your business model depends on uniqueness and premium pricing, OEM significantly reduces similarity risk.

3️⃣ Quality Control Risk

Solar garden lights are outdoor products exposed to:

- Rain and humidity

- Temperature fluctuations

- Battery degradation

- Long-term UV exposure

ODM

- Structure already tested, reducing engineering uncertainty.

- However, buyers have limited control over internal component selection (battery grade, LED bin, PCB thickness).

OEM

- Full control over battery supplier, LED bin selection, and waterproof sealing design.

- Higher development risk during early stages, but greater long-term quality consistency if managed properly.

Key Insight:

ODM reduces technical uncertainty.

OEM increases responsibility — but also control.

4️⃣ Warranty Risk

Warranty cost in solar garden lighting often relates to:

- Battery failure

- Water ingress

- PCB malfunction

- Brightness decay

ODM

- Warranty history already established for the model.

- Risk depends heavily on factory’s internal QC standards.

- Less flexibility to upgrade weak components after launch.

OEM

- Warranty responsibility increases during early production runs.

- However, component upgrades (higher cycle-life battery, improved sealing ring, thicker PCB coating) can reduce failure rates over time.

- Better suited for brands offering 2–3 year warranties.

Key Insight:

ODM offers predictable short-term stability.

OEM offers adjustable long-term durability strategy.

Final Consideration

For B2B buyers sourcing solar garden lights, the real decision is not:

“Which model is cheaper?”

It is:

“Which type of risk aligns with my business stage?”

- Startup sellers often prioritize speed and lower capital exposure (ODM).

- Established brands prioritize margin protection and differentiation (OEM).

- Many mid-sized buyers adopt a hybrid strategy — starting with ODM and gradually moving toward partial OEM customization.

Understanding these risk layers helps buyers choose strategically, not reactively.

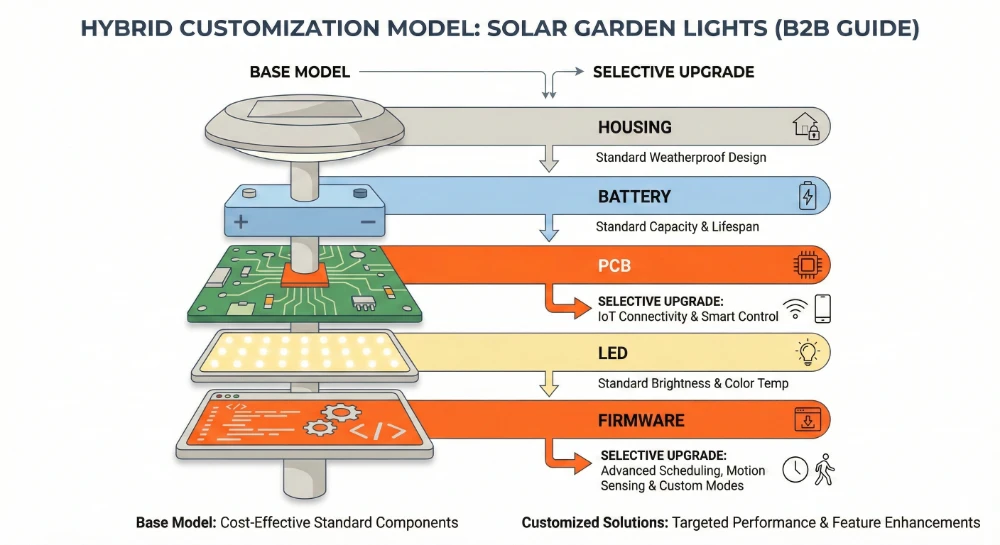

Hybrid Model – The Most Practical Approach

In reality, many experienced B2B buyers do not choose purely OEM or purely ODM.

Instead, they adopt a Hybrid Model — leveraging an existing proven structure while selectively upgrading key performance components. This approach balances speed, cost control, and differentiation.

For solar garden lights, this is often the most practical and commercially efficient strategy.

What Does a Hybrid Model Look Like?

Rather than developing a completely new mold, buyers can:

1️⃣ Upgrade Battery Specifications

- Replace standard 600mAh cells with 1200mAh or higher capacity

- Switch from NiMH to higher-grade Li-ion or LiFePO4

- Select branded battery suppliers for longer cycle life

Impact:

Longer lighting hours, lower warranty claims, stronger product positioning.

2️⃣ Adjust Light Source Parameters

- Change LED brightness (lumens)

- Modify color temperature (2700K warm white → 3000K / 4000K options)

- Improve LED bin consistency for better uniformity

- Optimize beam angle for pathway or decorative use

Impact:

Improved visual quality without redesigning the full structure.

3️⃣ Partial Structural Optimization

- Upgrade from IP44 to enhanced IP65 sealing

- Improve gasket thickness or waterproof ring design

- Strengthen solar panel frame material

- Reinforce ground stakes for better durability

Impact:

Higher outdoor reliability while keeping mold cost minimal.

4️⃣ Firmware or Control Logic Adjustment

- Add dual lighting modes (high/low brightness)

- Optimize charging curve for cloudy regions

- Integrate motion sensor sensitivity tuning

Impact:

Better user experience without complete PCB redesign.

Why the Hybrid Model Works Well in Solar Garden Lighting

Solar garden lights are performance-sensitive products.

Small component upgrades can significantly improve:

- Lighting duration

- Waterproof reliability

- Review ratings

- Repeat purchase rate

At the same time, avoiding full mold development:

- Reduces upfront investment

- Shortens development time

- Lowers market entry risk

Strategic Advantage for B2B Buyers

The hybrid approach allows you to:

- Enter the market quickly (like ODM)

- Control key performance elements (like OEM)

- Reduce direct product comparison

- Improve long-term margin stability

It is particularly suitable for:

- Growing private label brands

- Regional distributors expanding SKU lines

- Buyers transitioning from testing phase to brand-building stage

Practical Conclusion

For many solar garden lights buyers, the real decision is not “OEM or ODM.”

It is:

“Which parts of the product truly affect my competitiveness?”

If structure similarity is acceptable but battery life and durability define customer satisfaction, a hybrid strategy may deliver the highest return with the lowest structural risk.

In a market where speed and differentiation must coexist, the hybrid model often becomes the most sustainable path forward.

How Glowyard Supports Your OEM and ODM Strategy

At Glowyard, we understand that choosing between OEM, ODM, or a hybrid approach is not just a manufacturing decision—it’s a strategic business choice that affects your market positioning, inventory risk, and long-term profitability.

With over 15 years of experience in solar garden lighting manufacturing and export, we’ve helped hundreds of B2B buyers navigate this decision successfully. Here’s how we support different business models:

🟢 For ODM Buyers: Fast Market Entry with Proven Designs

If you need to launch quickly or test new markets, our ODM approach offers:

- 100+ Ready-to-Ship SKUs across decorative garden lights, memorial lights, and seasonal themes

- Low MOQ from 50 pieces for basic customization (logo, packaging)

- 7-10 day sampling with your branding applied

- Existing certifications (CE, RoHS, FCC, IP44-IP67) ready for documentation

- Proven performance data from existing customer feedback and warranty history

Our ODM models are ideal for:

- Amazon/eBay sellers testing new product lines

- Distributors preparing for seasonal peaks

- Importers needing fast replenishment

🔵 For OEM Buyers: Full Custom Development with Structural Control

If you’re building a brand that requires differentiation and long-term margin protection, our OEM capabilities include:

- Complete design freedom: Custom housing structure, lens design, battery configuration, PCB programming

- Mold ownership options: Negotiate exclusive or shared mold rights based on volume commitment

- Component-level control: Select your preferred battery supplier (Li-ion, LiFePO4), LED bin grade, and waterproof sealing design

- Engineering support: Our 15-20 person R&D team provides 3D modeling, structural optimization, and performance testing

- Certification assistance: We guide you through CE, RoHS, FCC, and regional compliance requirements

Our OEM process typically takes 90-180 days but delivers:

- Exclusive product structure

- Higher long-term margins

- Reduced price competition

- Stronger brand positioning

🟡 For Hybrid Buyers: The Best of Both Worlds

Many of our most successful clients adopt a hybrid strategy, and we’re equipped to support it:

Component Upgrades Without Full Mold Development:

- Upgrade battery capacity (300mAh → 1200mAh)

- Switch to higher-grade Li-ion or LiFePO4 batteries

- Improve waterproof rating (IP44 → IP65/IP67)

- Adjust LED brightness, color temperature, or beam angle

- Optimize PCB firmware for specific lighting modes

Partial Structural Modifications:

- Strengthen ground stakes or mounting brackets

- Enhance gasket thickness for better sealing

- Upgrade solar panel frame material

- Modify lens design for improved light distribution

Flexible MOQ Structure:

- Basic customization: 50-100 pieces

- Component upgrades: 300-500 pieces

- Structural modifications: 500-1000 pieces

- Full OEM development: 1000+ pieces

Why B2B Buyers Choose Glowyard

Manufacturing Capabilities:

- 8,000-12,000 sqm factory space across Guangdong and Fujian

- 5 production lines with monthly capacity of 50,000-80,000 units

- Advanced SMT assembly, battery testing, and waterproof sealing equipment

- ISO 9001 certified quality management system

Speed and Flexibility:

- ODM sampling: 7-10 days

- Small batch production (100-500 pcs): 15-20 days

- Bulk orders (500+ pcs): 25-35 days

- Urgent orders negotiable with rush fee

Quality Assurance:

- 4-stage inspection protocol (IQC, IPQC, FQC, OQC)

- Professional testing lab for IP rating, aging, and performance validation

- Defect rate target: <0.5%

- 2-3 year warranty on manufacturing defects

Business Support:

- Transparent cost breakdown (tooling, components, labor)

- Flexible payment terms (30% deposit + 70% balance; Net 30-60 for established clients)

- Multi-language support and 24-hour response time

- Design services, after-sales support, and technical troubleshooting

Strategic Consultation Approach

We don’t just manufacture—we help you choose the right model for your business stage:

- Startup phase? We recommend ODM with low MOQ to test market demand

- Growth phase? Hybrid approach with component upgrades for differentiation

- Established brand? Full OEM with mold ownership for maximum control

Our team has worked with clients across North America, Europe, Australia, and Southeast Asia. We understand regional preferences, certification requirements, and seasonal demand patterns.

Whether you’re sourcing Christmas solar lights, Halloween decorations, or year-round decorative garden lighting, we provide the manufacturing flexibility and strategic guidance to help you succeed.

Ready to discuss your project?

Contact our team for a free consultation and feasibility assessment.

Frequently Asked Questions from B2B Buyers

Below are some of the most common questions importers, distributors, and private label brands ask when sourcing solar garden lights under OEM, ODM, or hybrid models.

1️⃣ Can I request exclusive rights?

Yes — but exclusivity depends on the development model and agreement structure.

- ODM: Full structural exclusivity is uncommon unless you commit to volume targets or pay a mold reservation fee.

- OEM: If you invest in custom tooling, exclusivity is typically achievable, especially when mold ownership is clearly defined in contract terms.

- Hybrid: Partial exclusivity may apply if upgraded components (battery, PCB, firmware) are customized specifically for your order.

Always clarify whether exclusivity applies to:

- Mold structure

- Appearance design

- Regional market

- Online platform distribution

Exclusivity should be contract-based, not verbal.

2️⃣ What is the minimum order for custom tooling?

MOQ for OEM solar garden lights varies depending on:

- Mold complexity

- Product size

- Battery configuration

- Production line setup

In addition, tooling fees are usually separate from production MOQ unless amortized into long-term orders.

For hybrid customization, MOQ is often lower because existing molds are used.

3️⃣ Can I upgrade battery capacity?

Yes — this is one of the most common customization requests.

Possible upgrades include:

- Higher mAh capacity

- Switching battery chemistry (NiMH → Li-ion or LiFePO4)

- Selecting higher cycle-life battery grade

- Adding battery protection optimization

However, increasing battery capacity may require:

- Larger battery compartment space

- PCB charging adjustment

- Solar panel efficiency evaluation

Battery upgrades should always be technically validated to avoid overcharging or undercharging issues.

4️⃣ How long does sample development take?

Timeline depends on customization level:

- ODM sample with logo change: 7–15 days

- Hybrid upgrade sample: 15–30 days

- Full OEM structural sample: 45–90 days

For outdoor solar lights, samples should undergo:

- Waterproof testing

- Charging/discharging verification

- Basic aging test

Rushing the sampling phase may increase long-term warranty risk.

5️⃣ Who owns the mold?

Mold ownership must be clearly defined before development begins.

- If the buyer pays full tooling cost, ownership typically belongs to the buyer.

- If tooling is amortized into production orders, ownership terms may vary.

- ODM molds usually remain factory-owned unless a buyout agreement is made.

Important clarification points:

- Can the mold be transferred?

- Is it exclusive or shared?

- Is there a storage or maintenance fee?

Clear written agreements prevent future disputes.

6️⃣ Can certifications be transferred?

For most solar garden lights, certifications such as CE, RoHS, FCC, or regional compliance reports are issued for specific product structures and internal components.

- ODM: Existing certification reports can often be shared for documentation purposes.

- OEM: Structural or electrical modifications may require new testing.

- Certifications cannot simply be “transferred” if core components change.

Always verify:

- Whether the report matches your exact battery and PCB configuration

- Whether your brand name needs to appear on documentation

- Whether additional testing is required for your target market

Final Advice for B2B Buyers

Before choosing OEM, ODM, or hybrid development, clarify:

- Your target price positioning

- Expected order volume

- Desired product lifecycle

- Warranty commitment level

- Market competition intensity

In solar garden lighting, strategic clarity reduces costly revisions later in the supply chain.