How a Professional Factory Manufactures Crackled Glass Balls for Outdoor Lighting

Crackled glass balls look delicate and decorative, but behind each one there is a tightly controlled industrial process. These globes are commonly used in solar garden lights, string lights, table lamps and other decorative products, including series similar to globe & pebbles solar garden lights.

This article explains how a professional factory manufactures crackled glass balls, from raw material selection to final inspection, and how this process fits into a broader outdoor lighting manufacturing overview and glass solar lights manufacturing.

1. What Is a Crackled Glass Ball?

A crackled glass ball is a solid or hollow glass sphere with a network of internal cracks that create a sparkling effect when illuminated. The cracks are created on purpose by controlled thermal shock and then sealed so the surface remains smooth.

Typical uses:

- Decorative globes on stakes, posts or tabletops

- Shades for decorative solar garden lights

- Elements in globe & pebbles solar garden lights

In professional production, the goal is to make the glass beautiful, consistent and safe, while keeping unit cost competitive for mass markets.

2. Product Definition and Engineering Brief

Before any glass is melted, the factory and customer define a clear engineering brief:

-

Size and geometry

- Diameter of the ball (e.g. 80–120 mm).

- Hollow vs. solid, wall thickness or core thickness.

- Opening size if the ball must be mounted on a base or light holder.

-

Optical requirements

- Degree of crackle density (fine vs. coarse pattern).

- Transparency level and colour (clear, amber, blue, multi-colour).

- How the ball interacts with LED point sources or diffused light.

-

Mechanical / safety performance

- Minimum impact resistance for handling and installation.

- Edge safety around openings (no sharp edges).

- Compatibility with sealing and waterproof designs for solar lights.

This upfront planning is aligned with the broader philosophy described in Glowyard’s outdoor lighting manufacturing overview.

3. Raw Material Selection and Glass Composition

A professional factory starts with controlled glass batch materials:

- High purity silica sand, soda ash and limestone

- Optional colourants or metal oxides (for tinted crackled balls)

- Refining agents to reduce bubbles

Key considerations:

- Clarity and colour stability – important for decorative products.

- Thermal shock behaviour – must support the intentional cracking process without catastrophic failure.

For buyers comparing glass with other materials (metal, plastic, resin) in garden lights, Glowyard’s material overview is useful:

4 Materials for Solar Garden Lights You May not know.

4. Melting and Conditioning the Glass

The mixed batch is melted in a glass furnace:

-

Melting

- Batch is fed into a tank furnace and heated to ~1,400–1,600 °C.

- Fining processes reduce bubbles and homogenise composition.

-

Conditioning

- The molten glass flows into a forehearth where temperature is stabilised.

- Viscosity is adjusted for the forming method (blowing, pressing or mould-blowing).

Temperature stability is crucial to repeatable forming, especially when later thermal shock is applied for crackling.

5. Forming the Glass Ball

Crackled globes can be made with different forming methods; two common ones are hand-blown / semi-automatic mould blowing and press-mould forming.

5.1 Hand-blown or semi-automatic mould blowing

- A gob of molten glass is gathered on a blowpipe or automatic gob feeder.

- The gob is dropped or blown into a spherical mould.

- Air pressure shapes the glass to the mould’s inner surface, forming a hollow globe.

- Wall thickness is controlled by gob weight, blowing pressure and time.

5.2 Press-mould forming (for thicker or smaller balls)

- A gob is dropped into a spherical or hemispherical mould.

- A plunger presses the glass into shape.

- This method can create thicker-walled or solid spheres used for certain crackled effects.

At this stage, the glass balls are smooth and uncracked. The crackled effect comes in the next process.

The forming technology and equipment are consistent with general glass solar lights manufacturing.

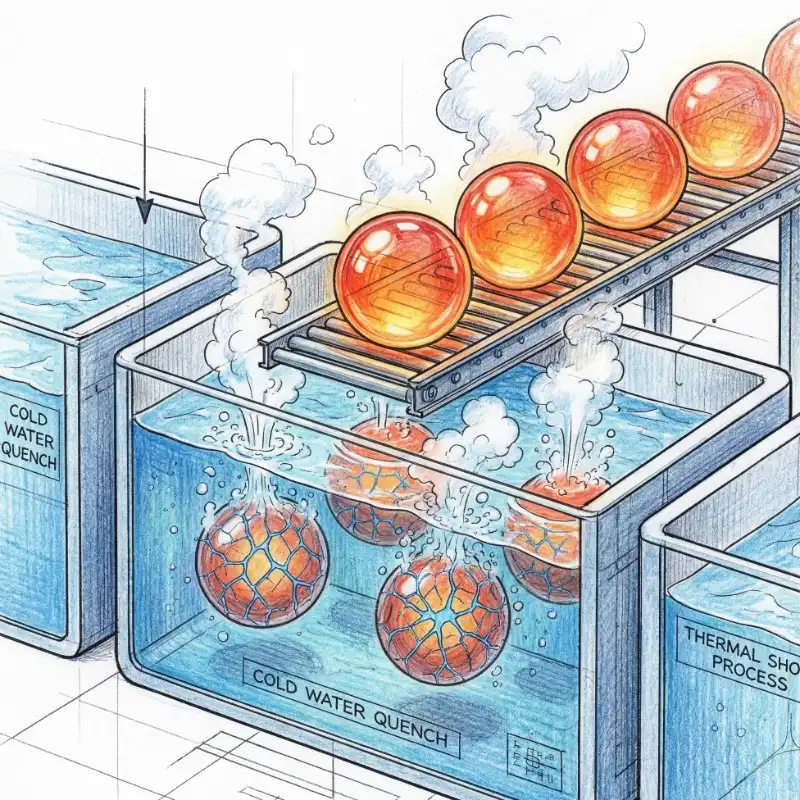

6. Creating the Crackled Effect by Thermal Shock

The distinctive crackled appearance is produced by controlled thermal shock:

-

Reheating

- Formed glass balls are reheated in a furnace or lehr to a temperature where the glass is still solid but hot (e.g. 400–600 °C depending on formulation).

-

Rapid cooling (quenching)

- The hot balls are quickly immersed in cold water or sprayed with cold water jets.

- The outer layer cools and contracts faster than the inner glass, generating a network of internal cracks.

-

Controlling crack density

- Water temperature, exposure time and glass thickness are adjusted to achieve the desired crackle pattern.

- Test pieces are examined visually to standardise the effect.

The key is to crack the interior without shattering the piece. This stage requires strict process control and experienced operators.

7. Reheating and Annealing to Seal the Surface

After crackling, the glass is structurally stressed. To stabilise it:

-

Surface reheating

- Balls are reheated in an annealing lehr so that the outer surface softens slightly.

- This can partially “heal” the outermost cracks and create a smooth, safe surface while keeping the internal crack network.

-

Annealing soak and controlled cooling

- The glass is held at a specific temperature to equalise internal stresses.

- Then cooled slowly according to a controlled curve to avoid new spontaneous cracks.

A well-designed annealing cycle ensures the crackled glass balls can survive handling, installation and typical outdoor temperature changes.

8. Cutting, Grinding and Edge Treatment

For balls that require an opening to mount on a base, stake or lamp holder:

- Opening creation – a hole is drilled or cut using diamond tools.

- Edge grinding – edges are ground and beveled to remove sharpness.

- Polishing – optional polishing improves appearance and reduces micro-cracks.

In decorative lighting, these steps must also coordinate with the mounting hardware and waterproof design described in Glowyard’s broader solar lights manufacturing guide.

9. Surface Finishing and Special Effects

Depending on the product design, the factory may add extra finishes:

- Colour coatings – translucent paints, gradient sprays or metallic coatings on part of the ball.

- Etching or sandblasting – to adjust diffusion and visual texture.

- Printing – simple patterns or logos where allowed by the light distribution.

These options are chosen to match specific product series within decorative solar garden lights or globe & pebbles solar garden lights.

10. Integration with Lighting Components

In many garden products, the crackled ball is integrated with LEDs and housings:

- The ball is mounted on a plastic or metal base designed according to the product’s IP rating.

- One or more LEDs are positioned to take advantage of the crackle pattern.

- Seals and adhesives are applied to protect the joint from water ingress.

This integration step connects the specialised glass process with the overall glass solar lights manufacturing workflow and the general outdoor lighting manufacturing overview.

11. Quality Control and Testing

Professional factories apply multiple inspection and test steps:

-

Visual inspection

- Check crackle uniformity, colour consistency and absence of large uncracked areas.

- Reject pieces with open cracks reaching the surface or sharp edges.

-

Dimensional checks

- Verify ball diameter, wall thickness and opening size tolerances.

- Ensure compatibility with mating bases or holders.

-

Mechanical and thermal testing

- Sample impact tests to simulate handling or minor knocks.

- Thermal shock tests (hot–cold cycles) to confirm stability in outdoor use.

These checks align with the factory-wide approach to durability across materials, as discussed in 4 Materials for Solar Garden Lights You May not know.

12. Cleaning, Packaging and Export Logistics

Finally, crackled glass balls are prepared for shipment:

-

Cleaning

- Dust and glass particles are removed through washing and air drying.

- Fingerprints and residues are minimised to keep the crackle effect clear.

-

Protective packaging

- Each ball is wrapped (e.g. foam, bubble or molded pulp) to prevent contact damage.

- When supplied as finished lights, packaging is integrated with the complete product box.

-

Cartoning and palletisation

- Units or sets are packed into inner boxes and then master cartons.

- Cartons are labelled with product codes, batch numbers and handling marks for export.

This packaging logic is consistent with what is described for complete garden lights in the outdoor lighting manufacturing overview.

13. How Crackled Glass Balls Fit into a Complete Product Strategy

Crackled glass balls are not just decorative components; they are part of a broader system of outdoor lighting products:

- They serve as key visual elements in glass-based solar garden lights, as described in glass solar lights manufacturing.

- They complement other materials such as plastic, metal and resin in a diversified product portfolio, covered in 4 Materials for Solar Garden Lights You May not know.

- Their production must align with the full solar lights manufacturing process in a Chinese factory, from electronics to final assembly and testing.

By understanding the complete factory production process for crackled glass balls—from raw materials and controlled cracking to integration with lighting systems—buyers can better evaluate suppliers, specify realistic requirements and develop consistent product lines for decorative outdoor lighting.