How a Professional Chinese Factory Manufactures Solar Garden Lights

Global buyers of solar garden lights often know the product catalogue very well, but see little of what happens behind the factory gate. At the same time, a large share of the world’s manufacturing capacity is now located in China, which naturally raises questions: why is so much production concentrated here, and what does a professional Chinese factory actually do from concept to shipment?

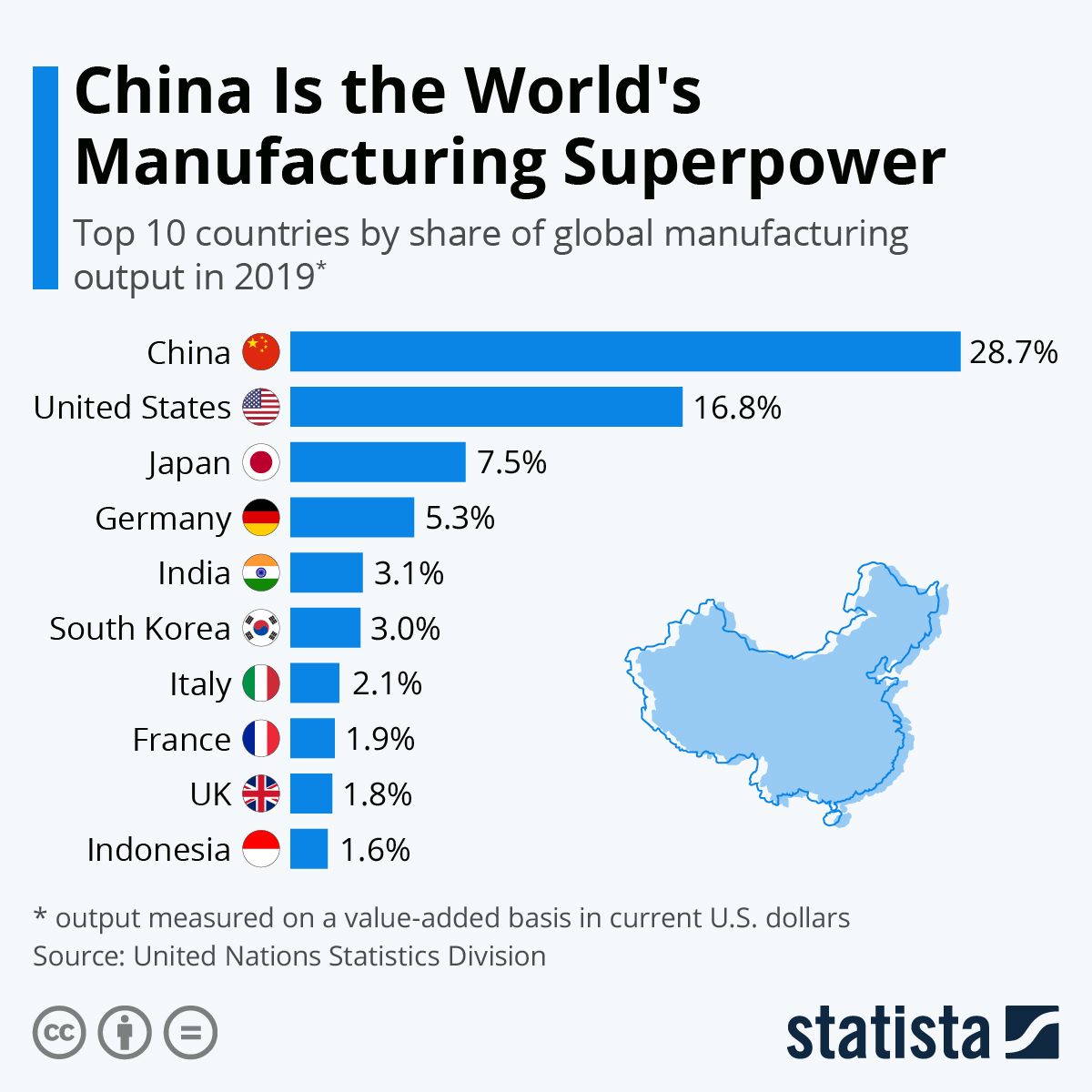

According to data compiled from United Nations statistics, China accounted for about 29% of global manufacturing output in 2023, making it the world’s largest manufacturing country by a wide margin. Manufacturing contributed roughly 27% of China’s total value added, far higher than the share in most advanced economies.1 This combination of scale, industrial clustering and experience is one of the main reasons why many solar garden lights sold in Europe or North America are ultimately produced in China.

This article takes an objective look at how a professional Chinese factory manufactures solar garden lights, from market requirements and product design, through materials and tooling, to fabrication, assembly, testing and export. The focus is on process and decision logic, rather than on any single company’s marketing story. A brief note at the end introduces Glowyard as one example of such a factory for readers who need a partner.

1. Why So Much Manufacturing Is Concentrated in China

1.1 Global scale and manufacturing share

Multiple datasets show how dominant China has become in global manufacturing:

- The United Nations Statistics Division data, summarized by Statista, indicate that China produced around 29% of global manufacturing output in 2023, far ahead of the United States in second place.1

- In value terms, China’s manufacturing sector added roughly US$4.8 trillion in 2023 and represented about 27% of China’s total economic output, making the country’s economy far more manufacturing‑intensive than most large economies.1

This scale matters for solar garden lights because the products depend on several supply chains—metals, plastics, glass, LEDs, batteries, electronics, packaging—that are all heavily developed in China.

1.2 Industrial clusters and complete supply chains

China’s manufacturing strength is not just about size, but about industrial clustering:

- Regions such as the Pearl River Delta (Guangdong), Yangtze River Delta, and parts of Fujian have dense networks of factories producing metal components, plastic housings, resin figures, glass globes, LEDs, batteries, PCBs, packaging and printing.

- Within these clusters, it is common to find specialized companies for tooling, surface treatment, SMT assembly, battery pack assembly, testing labs, and logistics within a short distance of each other.

For solar garden lights, this means a manufacturer can combine locally sourced components—metal stakes, injection‑moulded housings, resin figurines, glass balls, LED boards, batteries and printed boxes—into finished products with short lead times.

1.3 Cost structure and economies of scale

China’s cost advantage comes from a combination of factors rather than low labour alone:

- Labour + automation: Labour costs are higher than they were a decade ago, but factories have invested in automated equipment (CNC, stamping lines, SMT lines, automatic battery sorting, etc.), spreading equipment cost over large volumes.

- Economies of scale: High production volumes reduce the per‑unit cost of tooling, raw material procurement, testing and overhead.

- Experienced export infrastructure: Port capacity, freight forwarders and customs brokers are optimized for exports of manufactured goods, reducing friction and cost per shipment.

For solar garden lights—often relatively low unit‑value products—this cost structure is critical. A factory that can both scale and control quality is better positioned to keep retail prices competitive while meeting reliability expectations.

2. China’s Role and Advantages in Solar Garden Lights

2.1 Early entry and accumulated experience

China has been a major exporter of solar lighting products—including solar garden lights and street lights—for many years. Industry overviews and manufacturer listings show numerous Chinese suppliers specializing in solar garden, landscape and decorative lights alongside higher‑power solar street lighting.2 Over time, this has created:

- Large catalogues of proven designs (animals, flowers, lanterns, memorial themes, seasonal motifs, etc.).

- Accumulated knowledge about failure modes (water ingress, battery degradation, UV ageing) and how to reduce them.

- Familiarity with market preferences in different regions (for example, design language in Europe and North America vs. Asia).

2.2 Integration of decorative design and electronics

Solar garden lights sit at the intersection of decorative garden products and electronic lighting. Professional factories in China have learned to integrate:

- Structural and aesthetic design (metal, resin, plastic, glass) tailored to garden themes.

- Solar and LED technology (panel size, battery capacity, LED brightness and colour) matched to typical night‑time usage and local sunlight conditions.

This integrated capability is visible in the way many Chinese manufacturers and sourcing guides describe their services: not just as electronics assemblers, but as providers of customized decorative solar lighting solutions that highlight OEM/ODM and customization for garden and landscape applications.2

2.3 OEM/ODM and customization capabilities

Industry articles and sourcing guides on Chinese solar lighting factories commonly evaluate leading suppliers on factors such as customization expertise, MOQ flexibility, production scale, quality assurance and global support.2 In practice, this means:

- Ability to adapt appearance (shapes, colours, themes), materials (weather‑resistant plastics, metals, glass, resin) and efficiency (battery capacity, panel size) for different markets.

- Support for both OEM (customer‑owned designs) and ODM (factory‑designed products branded by the buyer), with corresponding MOQs.

- Experience exporting to Europe, North America, Southeast Asia and South America, with understanding of certification and packaging requirements.

This OEM/ODM ecosystem is one reason many international brands choose to source solar garden lights from China rather than setting up their own manufacturing.

| Aspect | OEM (buyer-owned design) | ODM (factory-owned design) |

|---|---|---|

| Design ownership | Buyer provides drawings/samples; IP usually owned by buyer | Factory provides base design; factory usually owns core IP |

| Customization depth | High, including structure and electronics | Typically appearance, materials, colours, light effects, packaging |

| Upfront tooling costs | Often borne by buyer (moulds, fixtures) | Often shared or initially covered by factory for strategic designs |

| Time to market | Longer (more engineering and validation) | Shorter (built on existing platforms and components) |

| Typical use case | Mature brands, exclusive collections | Faster testing of new styles and themes for retail and e-commerce |

3. Application Scenarios, Common Problems and Buyer Needs

3.1 Where solar garden lights are used

Solar garden lights are installed in a variety of environments:

- Residential: front and back gardens, flower beds, pathways, balconies, patios.

- Commercial: hotels, resorts, cafés, restaurants with outdoor seating, small theme parks.

- Memorial and cemetery: grave markers, memorial plaques, angel or cross lights.

- Seasonal and holiday: Christmas, Halloween, Easter and other festive decorations.

| Scenario | Typical installation examples | Key technical focus |

|---|---|---|

| Residential gardens | Pathways, flower beds, decks, balconies | Gentle brightness, appearance, easy install |

| Commercial hospitality | Hotel paths, resort landscaping, café terraces | Consistent look, robustness, safety |

| Memorial & cemetery | Grave markers, memorial statues and plaques | Respectful appearance, reliability, runtime |

| Seasonal & holiday | Themed decorations for festivals and special events | Visual impact, safe outdoor use, easy storage |

These different scenarios influence requirements for brightness, runtime, appearance, vandal resistance and waterproof rating.

3.2 Typical end‑user problems

Across markets, end‑user complaints about low‑quality solar garden lights are often similar:

- Lights stop working after a few months due to water ingress or poor battery quality.

- Rusting, fading or cracking housings, especially in coastal or high‑UV environments.

- Insufficient brightness or runtime, particularly in winter or cloudy regions.

- Unreliable sensors and switches, causing random on/off behaviour.

These problems are usually not caused by solar technology itself but by insufficient design margins, poor component choice or weak process control in manufacturing.

3.3 What professional buyers expect from a factory

Professional buyers—importers, brands, retailers and project companies—typically look for:

- Stability: consistent quality across batches and predictable defect rates.

- Outdoor durability: products that maintain appearance and function over 1–3 seasons or more, depending on positioning.

- Compliance: adherence to target‑market regulations (e.g., CE, RoHS, UKCA, UL, REACH for EU and North America).

- Customization capability: the ability to adapt designs quickly without reinventing the entire product.

- Transparent MOQ and lead times: clear expectations for sampling, trial orders and bulk production.

The rest of this article focuses on how a professional Chinese factory organizes its internal processes to meet these expectations.

4. From Concept to Product: Step‑by‑Step Manufacturing Process

The exact workflow can vary by factory and project, but a typical professional process for solar garden lights can be broken into ten major stages.

Step 1 – Market Requirements and Product Planning

A serious project starts with requirements, not with moulds or mass production.

-

Market and regulatory analysis

The factory (often together with the buyer) identifies target markets and relevant standards, such as CE and RoHS for the EU or UL/ETL for North America. This shapes decisions on insulation, creepage distances, materials and documentation. -

Application and product type definition

The team defines where and how the product will be used (pathway stake, wall light, hanging lantern, figurine, memorial stake, etc.) and whether the priority is decoration, functional light, or both. -

Performance targets and cost window

Key targets are set for brightness, runtime, colour temperature, lifespan, IP rating and projected retail price. These are translated into an allowable FOB cost range, which then guides material and structure choices.

Step 2 – Product Design and Engineering

Once requirements are clear, industrial design and engineering turn ideas into manufacturable concepts.

-

Industrial and aesthetic design

Designers create the outer form—animal, fairy, flower, lantern, minimalistic bollard, etc.—with attention to proportions, theme and brand fit. -

Mechanical and waterproof design

Engineers design internal structures, joints and sealing surfaces. For outdoor products, IP44 or IP65‑equivalent design principles are applied (gaskets, overlaps, drainage paths), drawing on industry practices summarized in waterproofing guides for garden lights.3 -

Solar and electronics design

The solar system is dimensioned: panel size and type, LED count and drive current, battery chemistry and capacity, control IC or discrete circuit, and optional sensors. The underlying PV module manufacturing (silicon purification, ingot growth, wafer slicing, cell fabrication and module lamination) typically follows processes like those described in the U.S. Department of Energy’s overview of crystalline silicon PV manufacturing.4 -

Prototyping and DFM (Design for Manufacturing)

Prototypes are made using 3D printing, soft tooling or hand‑built samples. A DFM review checks whether parts can be produced with stable tolerances and reasonable tooling cost. Adjustments are made to reduce part count, simplify assembly or improve sealing.

Step 3 – Material Selection and Supply Chain Setup

With a nearly final design, the factory confirms materials and suppliers.

-

Structural materials

Typical choices include:- Metals (cold‑rolled steel, galvanized steel, stainless steel) for stakes, posts and brackets.

- UV‑stabilised plastics (PP, ABS, PC, etc.) for housings and diffusers.

- Polyresin for figurines and statues.

- Glass for globes or shades.

-

Solar, LED and battery components

Many factories purchase standard PV modules or customized small panels from upstream PV manufacturers, who follow the silicon‑to‑module processes outlined in PV manufacturing literature.4 LED packages and lithium or Ni‑MH batteries are sourced from established component suppliers with relevant safety and performance data. -

Supplier evaluation and IQC

Suppliers are assessed for capacity, certifications and past performance. Incoming Quality Control (IQC) checks verify dimensions, material certificates, surface condition, basic electrical performance and visual quality before components enter production.

Step 4 – Tooling, Moulds and Fixtures

Solar garden lights rely heavily on repeatable tooling.

-

Metal dies and fixtures

Stamping dies, bending dies and welding fixtures define the geometry of metal components. Good fixtures allow operators to assemble parts in the correct position quickly and consistently. -

Plastic and resin moulds

Injection moulds for housings and diffusers, and casting moulds for resin figures, are designed with appropriate parting lines, draft angles and gating systems to avoid defects. -

Assembly and test fixtures

Jigs for positioning PCBs, panels and decorative pieces, as well as fixtures for functional and burn‑in tests, help standardize work and reduce operator error.

Tooling is a major upfront cost but is amortized across production volumes, which is one reason that higher volumes allow lower unit prices.

Step 5 – Metal Fabrication and Other Component Processing

While many details vary, the flow in a professional factory usually follows standard metal‑fabrication practice.

-

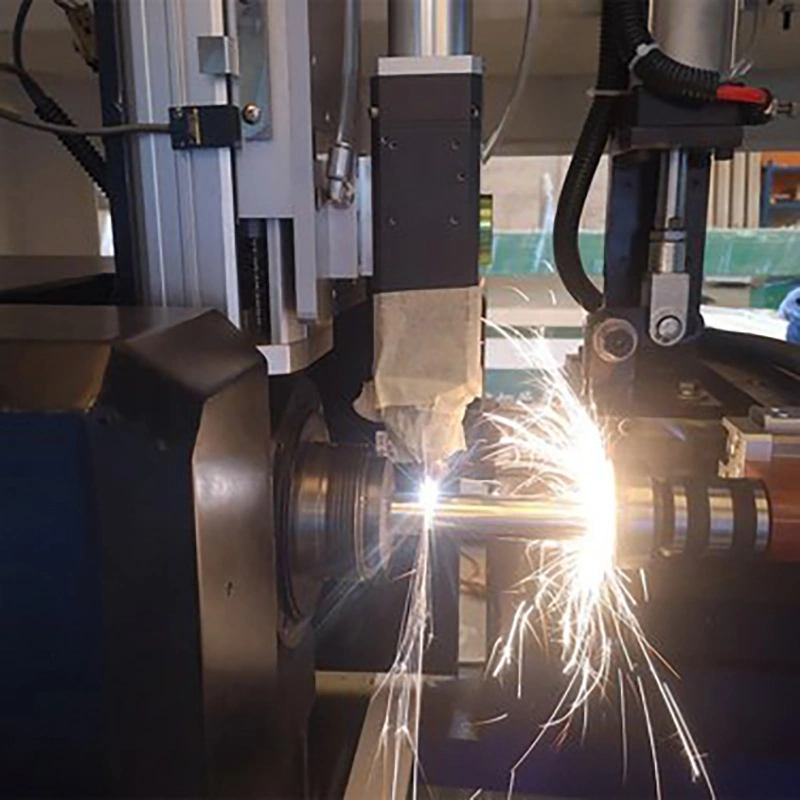

Cutting and forming

Sheets or profiles are cut (shearing, laser cutting, CNC punching) and then stamped, bent, drawn or rolled into shape. -

Joining

Components are joined by spot welding, continuous welding, brazing, screws or rivets, chosen according to strength and assembly requirements. -

Grinding and deburring

Weld seams are ground and edges deburred to remove sharpness and create a base for coating.

In parallel, plastic parts are injection‑moulded, resin parts are cast and finished, and glass parts are cut and edge‑ground. Each process has its own QC checkpoints for dimensions and appearance.

Step 6 – Surface Finishing and Anti‑Corrosion Treatment

For outdoor products, surface finishing is critical to long‑term performance.

-

Pre‑treatment

Metal parts go through degreasing and derusting; many factories also use phosphating or passivation to improve paint adhesion and corrosion resistance. -

Coating

Powder coating or wet painting is applied with specified film thickness and curing conditions. Special effects such as antique finishes or metallic textures are added as needed. -

Inspection

Visual inspection checks for runs, pinholes, orange peel and colour differences. Simple tests (e.g., cross‑hatch adhesion tests) may be performed for critical projects.

These practices align with general industrial coating standards and are adapted to the expected lifetime and price point of the solar garden light.

Step 7 – SMT, Electronics and Solar Modules

The electronics subsystem—PV, control, LEDs and battery—is the functional core of a solar garden light.

-

SMT assembly and AOI

Control PCBs are assembled using Surface Mount Technology (SMT), followed by reflow soldering and often automated optical inspection (AOI) to detect soldering defects. Industry sources describing solar lighting manufacturing emphasize the importance of reliable LED drivers and control circuits for longevity and energy efficiency.5 -

LED modules and optics

LED boards are designed for the desired lumen output and beam spread. Depending on the design, secondary optics (lenses, diffusers, patterned glass) shape the light. -

Battery packs and protection

Battery cells are sorted, assembled and fitted with protection circuits and insulation as needed. Charging profiles are matched to the chosen chemistry and panel size. -

PV modules

Most solar garden light factories integrate small finished PV modules produced by specialized PV firms that follow the well‑documented crystalline silicon production chain: polysilicon production, ingot and wafer manufacturing, cell fabrication and module assembly.45

Step 8 – Final Assembly, Waterproofing and Functional Testing

At this stage, decorative and functional modules are combined into a complete product.

-

Mechanical assembly and wiring

Operators follow standard work instructions to assemble housings, stakes or brackets, covers, PCBs, LEDs, batteries and switches. Wiring is routed and secured to avoid pinch points and vibration. -

Sealing and IP protection

Gaskets, O‑rings and sealant are applied at interfaces such as lens joints, cable entries and housing splits. The goal is to achieve the specified IP rating in real outdoor conditions, not just in theory.3

-

Functional tests

Each unit or sample in a batch is tested for:- Basic on/off and charging behaviour (often using simulated day/night cycles).

- Mode switching and sensor response (if motion or light sensors are used).

- Visual defects after assembly.

-

Reliability sampling

Depending on the project, samples undergo high/low temperature and humidity ageing, drop tests, vibration tests and, where relevant, salt‑spray tests for corrosion resistance.

Step 9 – Packaging, Warehousing and Global Shipping

Finally, the product must survive logistics and reach end users in good condition.

-

Packaging design and testing

Inner trays and inserts are designed to protect fragile components such as glass globes and panels. Drop tests and stacking tests help validate the design. -

Labelling and documentation

Cartons and products are labelled with barcodes, batch numbers and certification marks where applicable. Instruction leaflets and multilingual labels help reduce misuse and support compliance. -

Warehousing and logistics

Finished goods are stored using FIFO principles. Shipments are planned through major export ports (e.g., Shenzhen, Guangzhou, Xiamen for southern China), using sea freight for bulk orders and air/express services for urgent or sample shipments.

| Example packaging / logistics test | Typical method | Purpose |

|---|---|---|

| Carton drop test | Drop filled carton from set heights | Check resistance to impacts during handling |

| Stacking / compression test | Apply vertical load over time | Verify cartons withstand stacking in warehouses |

| Vibration test | Simulate truck or ship vibration | Detect loosening, noise or internal damage |

| Climate exposure check | Store samples in humid / hot conditions | Observe packaging deformation or print degradation |

Step 10 – Typical OEM/ODM Cooperation Workflow

The cooperation model between overseas buyers and Chinese factories usually follows a familiar pattern, which is also reflected in many Chinese solar lighting manufacturers’ OEM/ODM descriptions and independent sourcing guides.2

- Inquiry and requirement briefing

The buyer provides design references, target markets, expected quantities and price range. - Feasibility study and quotation

The factory’s engineering and costing teams review the design, suggest adjustments if necessary, and provide a quotation with indicative lead times and MOQs. - Sampling and optimization

Samples are produced and shipped for evaluation. Based on feedback, mechanical details, appearance or electronics may be refined. - Order confirmation and mass production

After final approval, mass production is scheduled, and the factory runs the full workflow described above. - Inspection and shipment

Internal or third‑party inspections verify quality before goods are shipped. - Reorders and continuous improvement

For repeat orders, data from previous batches and field performance are used to adjust design or process if needed.

5. Conclusion – Choosing the Right Chinese Manufacturing Partner

From an objective perspective, the value of a professional Chinese factory in solar garden lights lies less in any single machine and more in the combination of:

- Proximity to complete supply chains for metals, plastics, resin, glass, LEDs, batteries and packaging.

- Experience with international standards and outdoor reliability requirements.

- Ability to integrate decorative design with solar and electronic engineering.

- A structured manufacturing workflow that covers materials, tooling, fabrication, finishing, assembly, testing and logistics.

For buyers, the key is not simply “buying from China”, but selecting factories that have transparent processes, documented quality systems and realistic engineering approaches to outdoor products.

Glowyard is one example of such a specialist: it is a China‑based manufacturer focused on decorative solar garden lights and OEM/ODM cooperation with quality manufacturing for any materials. Readers who are looking for a supplier can learn more at glowyard. Whether you work with Glowyard or another supplier, understanding how a professional Chinese factory actually manufactures solar garden lights should make it easier to ask the right questions and build long‑term, reliable partnerships.

References

-

Felix Richter, "China Is the World’s Manufacturing Superpower", Statista, using United Nations Statistics Division data on global manufacturing output and China’s manufacturing value added, 2023. Available at: https://www.statista.com/chart/20858/top-10-countries-by-share-of-global-manufacturing-output/ ↩ ↩ ↩

-

Vorlane, "Top 10 Solar Light Manufacturers in China [2025 Updated]", listing multiple Chinese manufacturers specialized in solar lighting products (including garden lights) for global markets. Available at: https://vorlane.com/top-10-solar-light-manufacturers-in-china/ ↩ ↩ ↩ ↩

-

"IP Code", Wikipedia, describing the Ingress Protection rating system (e.g., IP44, IP65, IP67) and how the two digits classify protection against solids and liquids. Available at: https://en.wikipedia.org/wiki/IP_code ↩ ↩

-

U.S. Department of Energy, "Solar Photovoltaic Manufacturing Basics", especially the sections on silicon PV module manufacturing, polysilicon production, ingot and wafer production, cell fabrication and module assembly. Available at: https://www.energy.gov/eere/solar/solar-photovoltaic-manufacturing-basics ↩ ↩ ↩

-

Stephen Shickadance, "What are the Processes Behind Manufacturing a Solar Light?", Streetlights Solar, describing the use of silicon ingots (Czochralski method) in PV manufacturing and considerations in choosing LED fixtures for quality, longevity and energy efficiency. Available at: https://www.streetlights-solar.com/what-are-the-processes-behind-manufacturing-a-solar-light.html ↩ ↩