Why Injection Molding Is Critical for Plastic Solar Decorative Garden Lights

When people talk about solar decorative garden lights, they often focus on design, lumen output or battery capacity. In our factory experience, however, injection molding quality is just as important as electronics—especially for plastic housings.

Over the past 10+ years producing plastic solar garden lights for overseas brands, we have seen the same pattern again and again: when injection molding is well‑designed and well‑controlled, everything else in the project becomes easier—IP rating, appearance quality, assembly efficiency, even after‑sales performance.

At the same time, the outdoor solar LED market is expanding rapidly. According to a 2023 report by Straits Research, the global outdoor solar LED market was valued at around USD 7.54 billion in 2023 and is expected to reach USD 55.77 billion by 2032, with a CAGR of about 24.9% (2024–2032) (Straits Research, Outdoor Solar LED Market, 2024–2032). In such a fast‑growing and competitive market, ignoring injection molding can quickly erode profit and brand reputation.

A Brief History and Global Market of Injection Molding

A short history of plastic injection molding

From an industry history perspective, plastic injection molding is not a new technology. According to historical overviews from technical sources such as Xometry and New Berlin Plastics, the first recognizable injection molding machine was patented in 1872 by brothers John Wesley Hyatt and Isaiah Hyatt in the United States. Their early machines used a simple heated cylinder and plunger to process celluloid.

In the 1930s–1940s, engineers like James Watson Hendry introduced the first screw‑type injection molding machines, which allowed much more precise control over melting, mixing and injection. After the Second World War, the rapid development of new thermoplastics and automation made injection molding one of the dominant methods for producing plastic parts in consumer goods, automotive, appliances and electronics.

In our own projects, we feel the benefit of this long evolution every day: modern machines and controls make it possible to repeat the same housing design hundreds of thousands of times with very tight tolerances, as long as the tooling and process are engineered correctly.

Key milestones in plastic injection molding history (overview):

- 1872 – First injection molding machine patented by John and Isaiah Hyatt (celluloid processing).

- 1930s–1940s – Screw-type injection molding machines introduced (James Watson Hendry).

- Post‑1945 – Rapid expansion with new thermoplastics and automation.

- 2000s–2020s – Widespread use across consumer goods, automotive, electronics and lighting.

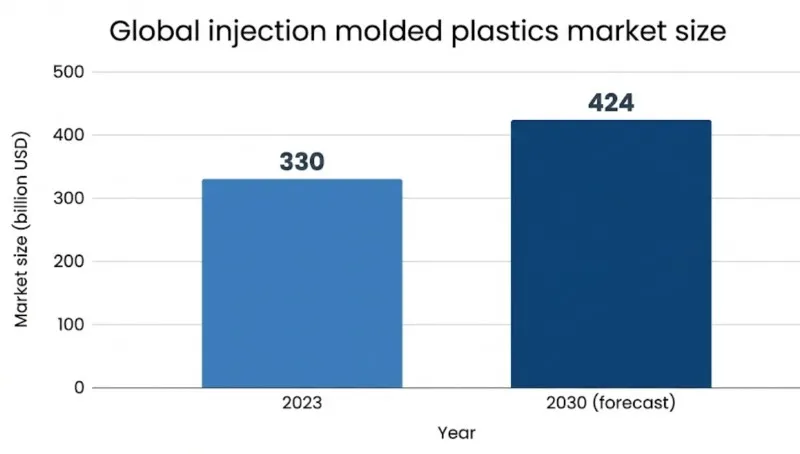

Global market size and growth

Beyond solar lighting, injection molded plastics are a massive global industry in their own right. Grand View Research estimates that the global injection molded plastics market was worth around USD 330 billion in 2023, and is projected to reach approximately USD 424 billion by 2030, growing at a CAGR of about 3–4% from 2024 to 2030 (Grand View Research, Injection Molded Plastics Market, 2024–2030).

This scale matters for buyers of solar garden lights for two reasons:

- Injection molding benefits from huge economies of scale in materials, machines and know‑how.

- Continuous investment from automotive, packaging and consumer goods industries keeps pushing the technology forward, and lighting manufacturers can leverage these advances.

When we design a new plastic housing for a solar decorative light, we are standing on more than a century of accumulated process development and a global industry worth hundreds of billions of dollars.

Why Chinese injection molding is widely chosen

According to industry statistics compiled by Statista, China has been the world’s largest producer of plastic materials for years, accounting for roughly one‑third of global plastic materials production in the late 2010s and early 2020s. Separate analyses of China’s plastics and injection molding sector also highlight that the country hosts tens of thousands of plastics and plastic products manufacturers, supported by a dense network of material suppliers and machine builders.

Based on both public data and our direct experience working with Chinese injection partners, buyers tend to choose China for plastic housings for three main reasons:

- Scale and ecosystem – A very large base of plastics processors and mold makers, plus local producers of injection molding machines and auxiliary equipment, creates strong cost and lead‑time advantages.

- Experience with consumer goods and lighting – Many factories have decades of experience making small to medium‑sized decorative parts, including housings, stakes and diffusers similar to those used in solar garden lights.

- Flexibility on volume and customization – Because of the depth of the ecosystem, it is often easier to find partners in China who can balance custom designs with realistic MOQs and competitive pricing.

From Glowyard’s perspective, this is why we adopt an “asset‑light, R&D‑heavy” model: we keep design, SMT, assembly and QC in our own hands, while leveraging specialized Chinese injection molding partners for high‑quality housings. This combination lets us focus on value‑adding engineering while still benefiting from the country’s mature injection molding supply chain.

What Injection Molding Really Does for a Solar Garden Light

From the outside, a plastic solar decorative light looks simple: a body, a lens or diffuser, a stake and maybe a decorative top. Inside the factory, the plastic housing is doing much more than just “holding the parts together”.

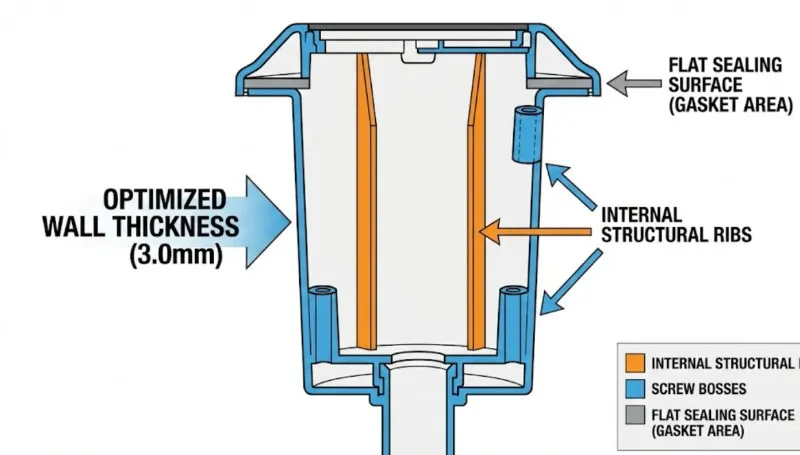

From our injection molding projects for plastic solar lights, we see that a good housing must:

- Provide mechanical strength so the product survives shipping, installation and outdoor use.

- Protect internal electronics against water and dust ingress.

- Maintain appearance quality (gloss, colour, texture) over years of UV exposure.

- Ensure dimensional accuracy so snap‑fits, screws and seals align at assembly.

Injection molding is the process that decides whether the housing can deliver all of these at the same time, at scale.

Factory experience: Whenever we trace high defect rates or unstable IP performance back to the root cause, more than half of the time the real issue is related to tooling design or injection process control, not just “bad workers on the line”.

How Plastic Solar Light Housings Are Made

Plastic housings for solar garden lights are typically produced by injection molding. A simplified process looks like this:

- Part and mold design – engineers design the housing with draft angles, ribs, wall thickness and sealing features that are suitable for molding and assembly.

- Tooling fabrication – a steel mold is built with cavities, runners, sprues and cooling channels.

- Injection molding – plastic granules are melted and injected into the mold under controlled temperature, pressure and time.

- Cooling and ejection – the part cools inside the mold and is ejected by pins or other mechanisms.

- Trimming and inspection – gates, flash and minor defects are removed, and the part is checked.

Glowyard focuses on high‑value steps such as R&D, SMT, assembly and QC, while injection molding is handled via strategic partners that specialise in this process. However, we treat their machines and molds as an extension of our own factory: design reviews, parameter windows and quality standards are defined together.

For a detailed view of how plastic housings tie into the complete production flow, you can refer to our plastic lights manufacturing process.

What Can Go Wrong When Injection Molding Is Weak

When injection molding is not handled professionally, solar decorative garden lights may look fine in the catalogue but fail in the field.

Typical defects we see in plastic solar housings

- Flash and burrs – thin layers of excess plastic along parting lines, making assembly difficult and causing water paths.

- Short shots – incomplete filling, especially on thin ribs or corners.

- Sink marks & warpage – uneven cooling or poor design causing dents and distortion.

- Stress whitening and cracks – from aggressive demoulding, poor material or incorrect processing.

- Dimensional drift – housing and mating parts do not fit properly after a few thousand shots.

These issues are not only cosmetic. They directly impact waterproof performance, structural stability and assembly cost.

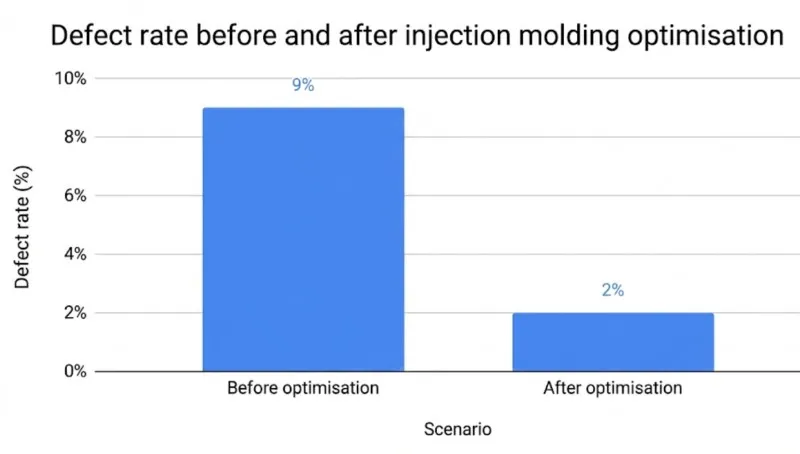

Example: How process optimisation changes defect rate

In one series of decorative solar garden lights, we helped an OEM client optimise injection molding for the plastic stake and housing. Before optimisation, the main issues were warpage and loose fit at the joint.

We re‑analysed the part and mold, adjusted gate position and refined injection and cooling parameters. Internally, our before/after defect rates looked like this:

Example: defect rate before vs after optimisation (internal data)

| Scenario | Defect rate (%) |

|---|---|

| Before optimisation | 9 |

| After optimisation | 2 |

This is only one internal example, but it reflects a common pattern: once injection molding is stabilised, quality issues across the line drop sharply.

Injection Molding and Outdoor Durability

For outdoor solar decorative lights, plastic is constantly exposed to UV, temperature changes and humidity. Even if the electronics are well‑designed, poor injection molding can make the product fail early.

Wall thickness, ribs and UV ageing

From our projects, we have learned:

- Over‑thick sections tend to sink and crack under temperature cycles.

- Too thin sections become fragile and vulnerable to impact or stress.

- Properly designed ribs and bosses support structure without creating stress concentration.

Injection molding is the only stage where these structural details can be firmly “locked in”.

For readers interested in plastic durability under sun exposure and how material choices interact with process, see also our guide on improving plastic durability in solar garden lights.

How housings support waterproof design

Waterproofing in solar garden lights (IP44, IP65, etc.) depends heavily on:

- Flat, dimensionally stable sealing surfaces

- Consistent groove and gasket geometry

- Correct snap‑fit or screw compression around sealing lines

Poor injection molding will warp sealing surfaces, misalign screw bosses and reduce gasket compression. In practice, we see this directly in IP tests: products with unstable molding performance need more rework and sealing “patches” at assembly, and still show higher leakage rates in random sampling.

Why Injection Molding Matters for Cost, MOQ and Lead Time

From a buyer’s perspective, injection molding may feel like a one‑time upfront cost. In reality, it influences almost every unit cost component.

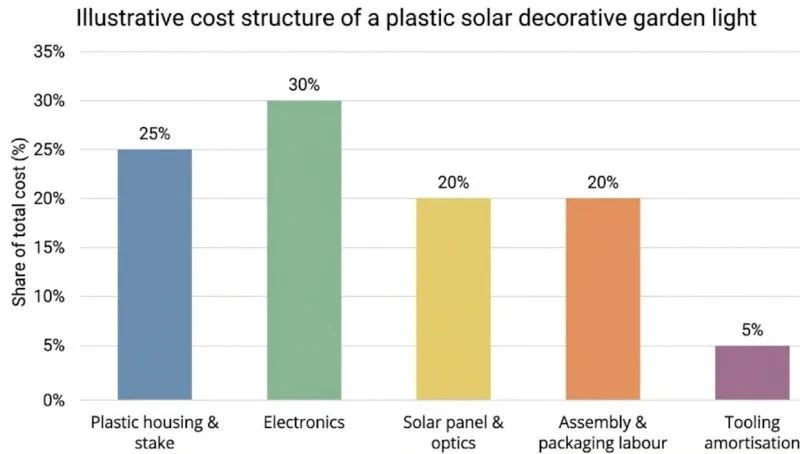

Cost structure: where injection molding sits

A simplified cost view for a plastic solar decorative light might look like this:

| Cost Element | Typical Share (Illustrative) | How Injection Molding Influences It |

|---|---|---|

| Plastic housing & stake | 20–30% | Scrap rate, cycle time, material yield |

| Electronics (PCB, LED, battery) | 25–35% | Housing tolerances affect assembly efficiency and rework |

| Solar panel & optics | 15–25% | Housing geometry affects integration and protection |

| Assembly & packaging labour | 15–25% | Fit & finish affect assembly time and rework |

| Tooling amortisation | 5–10% | Mold life and stability decide actual amortised cost per pc |

Better injection molding reduces scrap, rework and downtime, and extends mold life. This keeps the effective cost per unit stable even at lower MOQs.

Impact on MOQs and flexibility

Because Glowyard works with shared molds and modular designs for many plastic solar lights, we can often support lower MOQs than the industry average. But this only works when molds and processes are stable enough that each restart or variant does not require days of re‑debugging.

When injection molding is disciplined, we can:

- Ramp up new colours or minor cosmetic changes with minimal extra cost.

- Restart production for seasonal orders quickly, even after a gap.

- Offer trial orders at lower quantities without hidden process risk.

Evaluating a Supplier’s Injection Molding Capability

If you are selecting a partner for plastic solar decorative lights, you may not be able to stand next to their injection machines every day. But you can still ask targeted questions that reveal their level of control.

Questions to ask

- How do you handle DFM (Design for Manufacturing) before mold fabrication?

- Do you provide documented process windows and parameter sheets for important molds?

- How do you track mold health and preventive maintenance?

- Can you share real examples of defect rate improvement after process optimisation?

- How do your injection partners connect with your main assembly and QC processes?

The answers will show whether the supplier treats injection molding as a strategic capability or just a black box.

What we have found works in practice

In our projects, the most effective approach has been:

- Involving production and QC staff early in mold design.

- Treating mold trials as a structured experiment, not just a one‑time approval.

- Creating simple but consistent mold health records.

- Integrating injection partners tightly with our overall outdoor lighting manufacturing process, from IQC to final assembly and testing.

How Injection Molding Links to OEM/ODM Success

For OEM/ODM projects, customers often care about two things at the same time:

unique design and reliable, repeatable production.

Injection molding is the bridge between these goals:

- It converts 3D concepts into mass‑producible parts.

- It determines whether a design can survive multiple seasons outdoors.

- It decides how stable quality will be when you reorder or scale up.

When we discuss new OEM projects with clients, we always include a tooling and molding section in the plan:

- Whether to use existing shared molds or build new tools.

- Expected amortisation period and MOQ scenarios.

- Risks related to housing geometry, wall thickness and sealing.

- Time allowed for mold trials and optimisation before final approval.

If you want to explore a custom plastic solar decorative light and need both design and manufacturing support, our OEM solutions for solar garden lights are built around this combined approach.

Conclusion: Injection Molding as a Strategic Lever, Not a Background Detail

For plastic solar decorative garden lights, injection molding is not just a technical detail hidden behind the catalog photo. It is a strategic lever that influences:

- Outdoor durability and waterproof performance

- Visual quality and brand perception

- Realistic MOQs and flexibility for seasonal products

- Total cost and profit over the life of a project

By combining real factory experience with disciplined tooling and process control, Glowyard uses injection molding as a foundation for fast sampling, fast shipping and competitive MOQs—rather than a hidden risk.

For buyers and brand owners, paying attention to your supplier’s injection molding capability is one of the most effective ways to protect your project before the first container even leaves the factory.

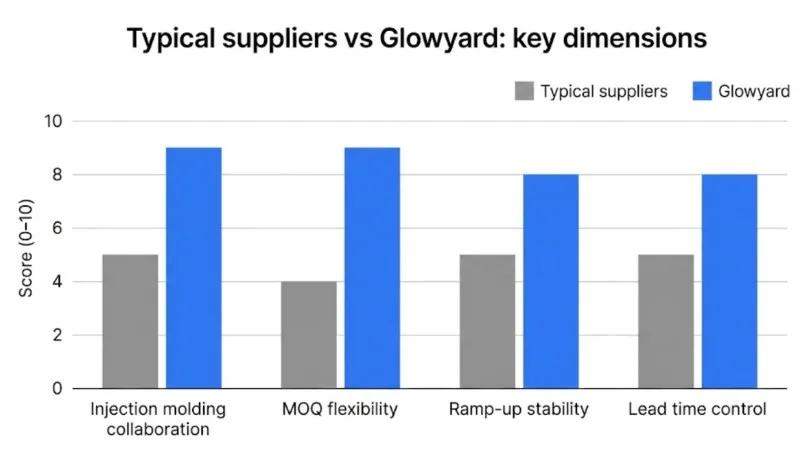

Why Glowyard Is a Strong Partner for Plastic Solar Decorative Outdoor Lights

When you choose a supplier for plastic solar decorative outdoor lights, you are not only buying a product catalogue—you are choosing a tooling strategy, a process discipline and a cost structure. Based on both public market benchmarks and our own project data, Glowyard is positioned differently from many typical suppliers in several key areas:

| Dimension | Typical suppliers (summary) | Glowyard approach (summary) |

|---|---|---|

| Injection molding collaboration | Mold design and production often separated; limited DFM feedback | Cross-functional DFM with injection partners; documented process windows and mold health records |

| MOQ for customised plastics | 200–500 pcs for appearance tweaks; 1000+ pcs for functional changes | Simple appearance tweaks from around 50 pcs; deeper customisation with transparent tooling amortisation |

| Ramp-up and re-order stability | Longer debugging and re-tuning when restarting seasonal SKUs | Parameter sheets and mold records allow faster restart and more predictable reorders |

| Lead time for typical orders | Highly variable; dependent on mold room and workshop congestion | Structured sampling (7–10 days) and production windows based on a defined OEM/ODM process |

For buyers who want to understand specifically how we align mold design and mass production to support fast delivery and lower MOQs, we have prepared a dedicated guide: How We Align Mold Design and Mass Production to Enable Fast Delivery and Low MOQs.

If you are evaluating suppliers for a new plastic solar decorative outdoor light project, sharing your target design, expected volumes and timeline with Glowyard early will allow us to propose a realistic plan that balances customisation, cost and risk from the very first tooling discussion.