“Specializing in solar garden lights wholesale, with five production lines, committed to providing high-quality, cost-effective, and innovative lighting solutions for Europe, North America, Russia, and Australia markets.”

Our glass workshop produces crackle globes, lantern covers, patterned shades and frosted finishes tailored for garden solar lights. We combine mold forming, toughening, coating and color spraying to achieve beautiful visual effects with robust outdoor durability. In-house glass production ensures better stability, faster delivery and lower defect rates for OEM/ODM orders.

Enhance Durability, Light Quality, and Decorative Value

In outdoor solar lighting, the choice of glass directly shapes the lamp’s appearance, durability, and night-time ambience. At GlowYard, we offer multiple glass styles to match different market needs—from premium hand-blown décor lights to cost-efficient mass-production models.

Benefits

Strong decorative value

Beautiful light dispersion patterns

Limitations

Higher breakage risk and material cost

Common Uses

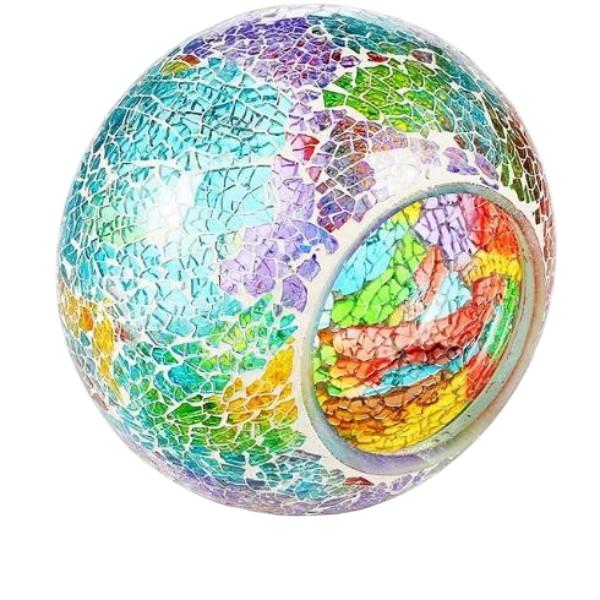

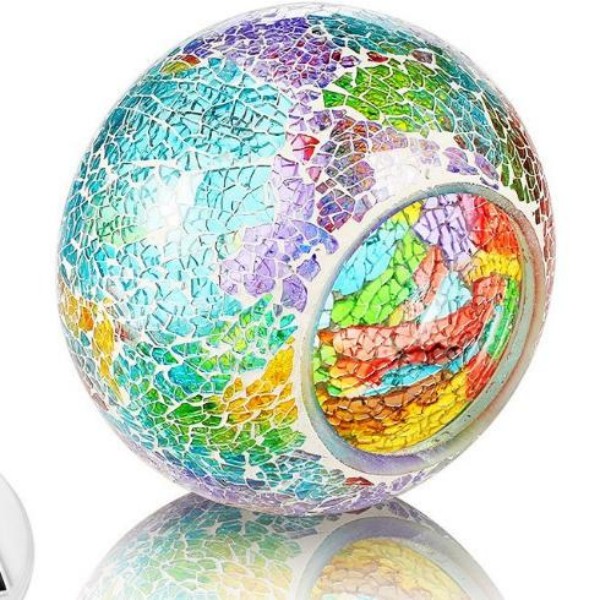

Crackle balls, hanging ornaments, solar string balls.

Benefits

Creates colorful, artistic light patterns at night

Strong emotional value for gifting and home décor markets

Limitations

Labor-intensive process with higher production cost

Surface needs extra protection for outdoor environments

Common Uses

Solar table lamps, décor ball lights, boho-style lanterns, lifestyle garden ornaments.

Benefits

Versatile design styles at a lower cost

Suitable for custom themes and brand collections

Limitations

Outdoor UV exposure may cause fading if not well-coated

Common Uses

Decorative table lamps, hanging solar jars, lifestyle collections.

Benefits

Strong visual impact and artistic atmosphere

Unique night-time glow

Limitations

Higher cost and possible color variation

Common Uses

Artistic garden lights, festive solar décor, premium lanterns.

Benefits

Premium look for high-end retail markets

Each piece has unique texture and patterns

Limitations

Higher price and limited production capacity

Common Uses

Boutique garden lights, designer collections, brand-exclusive pieces.

Benefits

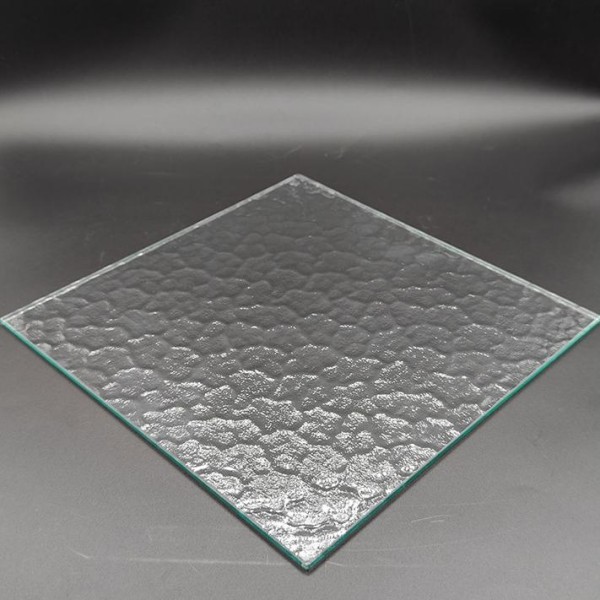

Eliminates glare from point-light LEDs

Provides uniform ambient lighting

Limitations

Lower light transmission—requires brighter LEDs

Common Uses

Solar table lamps, ambient ball lights, pathway lights.

Benefits

Maximum brightness output

Ideal for filament-style decorative LEDs

Limitations

Without diffusion, the LED may appear too harsh

Common Uses

Edison-style solar lanterns, decorative hanging lights.

Benefits

High safety and outdoor durability

Suitable for IP65+ structural lamps

Limitations

Modern, rigid appearance—not ideal for rustic styles

Common Uses

High-power wall lights, pillar lamps, security-style garden lights.

Benefits

Decorative look with soft, diffused light

Helps hide LED beads and elevates product aesthetics

Limitations

Heavier and requires high-precision molds

Common Uses

Lantern-style garden lights, vintage solar lights, pillar lights, wall lights.

A step‑by‑step overview of how glass components for outdoor solar lights move from raw material batching and melting to forming, finishing, decoration, assembly and reliability testing.

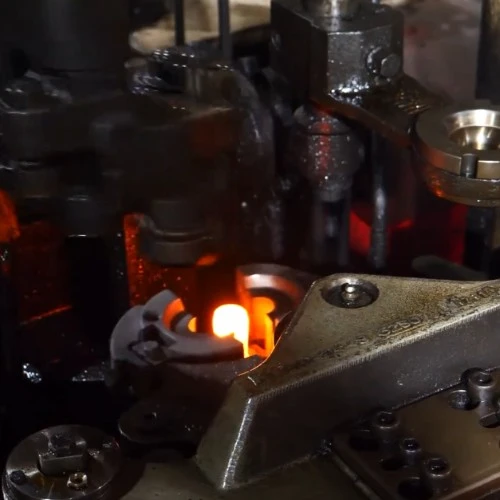

Our garden light glass housings are produced on a 9S fully automatic glass bottle production line, enabling both large-volume manufacturing and high-precision customization for global buyers.

The 9S system integrates feeding, molding, blowing, annealing, and quality inspection into one continuous automated process. This ensures consistent wall thickness, perfect spherical shape, and superior optical clarity—ideal for garden solar lights requiring durability and aesthetic appeal.

With flexible mold-switching and stable production speed, we support:

Custom diameters and shapes (spheres, cylinders, jars, mosaic bases, etc.)

Various glass textures (frosted, crackle, colored, patterned)

High-volume seasonal orders for retail and e-commerce programs

OEM/ODM projects requiring exclusive molds and branding

The automated line reduces defects, improves consistency, and guarantees reliable output even during peak ordering seasons. Whether you need premium crackle balls, large-size glass globes, or unique decorative shapes, our production line delivers precision, transparency, and repeatable quality at scale.

Our premium glass shades are crafted by skilled artisans using traditional hand-blowing techniques, allowing us to create shapes and textures that automated machines cannot replicate. Each piece carries its own unique character—perfect for brands seeking distinctive designs and elevated product aesthetics.

With full in-house capability, we can produce:

Organic shapes such as droplets, waves, swirls, bubbles, and irregular art forms

Large-size globes with custom thickness and transparency

Color-infused glass (amber, blue, smoke, gradient tones)

Texture-rich finishes including crackle, rippled, frosted, or mixed techniques

Hand-blown craftsmanship gives your outdoor lighting collections a premium, artistic touch, making them ideal for boutique retailers, designer collaborations, and high-end garden décor lines.

Every piece is shaped, cooled, trimmed, and inspected by our professional glass masters, ensuring:

Exceptional clarity and smooth finish

Stronger structure compared to common artisan glass

Repeatable quality even for small-batch OEM orders

Flexible customization for exclusive SKU development

Whether you need signature pieces or limited-edition glass designs, our hand-blown capabilities bring your concepts to life with unmatched artistry and precision.

Key glass-related capabilities—from composition and color control to forming, tempering and surface finishing—that support durable, premium-looking outdoor solar garden lights.

Explore representative glass-based outdoor and solar lighting designs—such as crystal-clear path lights, frosted garden globes and patterned wall lanterns—that are manufactured using our glass forming, finishing and assembly capabilities.

Common problems importers face with glass outdoor lights, from breakage and inconsistent appearance to glare issues and sealing failures.

Poorly tempered or insufficiently annealed glass, combined with weak packaging, leads to cracks and shattering before products even reach store shelves.

Incorrect choice of glass texture and thickness creates harsh hotspots or uneven light, making the product look cheap and uncomfortable to use.

Unstable glass recipes and loose process control cause visible bubbles, streaks, color variation and surface waves across different batches.

Weak coordination between glass parts and housings results in gaps at seals, letting in rainwater and moisture that damage LEDs and electronics.

To understand how these issues appear across the whole production chain, you can review our outdoor lighting manufacturing overview.

Our glass engineering, forming and finishing methods are designed to keep glass parts stable and premium-looking outdoors, while matching your target cost.

We select and adjust glass compositions for clarity, color stability and strength, rather than relying on generic glass intended for indoor decoration only.

Our R&D team balances wall thickness, curvature and texture so each diffuser delivers the desired light effect while staying robust in handling and assembly.

Standardized pressing/blowing parameters and annealing or tempering cycles reduce internal stress, warping and spontaneous breakage issues.

Glass parts, gaskets, frames and fasteners are co-designed so joints stay tight, maintain IP performance and look neat after assembly.

How our multi-stage QC system—from raw glass batch control to final packaging tests—reduces complaints and returns for glass-based outdoor lights.

Our factory holds BSCI, ISO 9001, and Sedex audits, and our products comply with CE, RoHS, FCC, UL, UKCA and more.

Key questions to ask and data to request from factories so you can balance appearance, durability, tooling investment and long‑term program stability for glass products.

In your RFQ, specify whether you need soda‑lime, borosilicate or tempered glass, target thickness range and any safety standards to meet for public use.

Approve a glass sample under both day and night viewing; require any change in recipe, texture or coating to be re‑approved against that standard.

Align glass shape and fragility with inner packaging design, pallet stacking limits and drop-test requirements to avoid damage in transit.

Special molds, textures and coatings require higher tooling cost and MOQ; reserve deep customization for core SKUs and use lighter tweaks on trial or seasonal items.

For more practical details on MOQ, lead times and ordering flow, refer to our purchasing guide for solar garden lights.

Practical guides, FAQs and insights on glass material selection, tempering, surface finishing, waterproof design and production best practices to help buyers design and source better glass-based outdoor lights.

Glass solar lights bring a premium, refined feeling to outdoor spaces. Compared with all-plastic options, glass gives you clearer light, richer textures and a more upscale appearance. When combined with metal or quality plastic structures, glass can support both decorative and functional lighting for gardens, terraces and pathways.

This buyer’s guide explains the key decisions you should make when developing or sourcing glass solar lights for your brand. It is written for importers, wholesalers, retailers and brand owners who want to use glass to upgrade certain ranges while keeping outdoor performance and safety under control.

Each housing material plays a different role in a complete assortment. Glass solar lights are typically used to:

Plastic is usually chosen for high-volume, price-sensitive programs; resin for figurines and themed decor; metal for structural strength and long-term durability. Glass sits between them as the material that contributes the most to visual quality and light effect. Decide clearly where glass adds real value in your category and avoid using it in positions where breakage risk or handling conditions are not acceptable.

Glass is well suited for:

On the other hand, for ground stakes in high-traffic public areas or children’s play spaces, plastic lenses or fully plastic housings may be more appropriate due to lower breakage risk. Understanding where glass is realistically safe and appreciated helps you choose the right SKUs for glass solar designs.

Several glass types are used in outdoor solar lights, each with different properties:

Discuss with your supplier which glass types are proposed for each component and whether tempering is required by your market or project specifications.

Good glass design balances aesthetics, weight and safety. Important decisions include:

Clarify with your supplier:

Especially for larger pieces, you should also review how glass and supporting metal/plastic components share loads, so that no small contact area carries too much stress.

Glass will always be more fragile than plastic, but design choices can significantly reduce breakage risk:

Ask your supplier to comment honestly on breakage risks in your initial designs and to propose reinforcements or alternative configurations where necessary. This is especially important for larger online or retail programs where returns due to breakage can be costly.

Glass is a key element in defining how light looks and feels. When planning your glass solar lights, consider:

Work with your supplier to match LED brightness, colour temperature and optics to the glass type so the final effect matches your brand promise. Request lit sample photos or videos in dark environments during development.

Glass can be decorated and finished in several ways:

Each technique has its own cost and durability characteristics. Discuss:

Agreeing on clear decoration samples and test criteria avoids surprises when mass production begins.

Most glass solar lights combine glass with other materials. Key interface questions include:

Ask for detailed section drawings or sample photos that show how glass is held in place. Well-designed interfaces minimise stress on glass, allow for assembly and service, and help maintain IP rating.

Water protection with glass is not just about the glass itself; it depends on the full enclosure design:

Condensation is another real-world issue. In some climates, small amounts of condensation on inner glass surfaces may be acceptable if they evaporate quickly, but standing water or repeated heavy condensation can affect electronics and appearance. Discuss with your supplier how they test for and manage condensation in closed glass designs.

In many designs, the solar panel is separate from the main glass housing. However, when glass covers or surrounds the panel:

Clarify whether any glass is positioned over the solar panel, which glass type is used there and how the design supports cleaning and ventilation. For important projects, request performance data under real sunlight conditions, not only theoretical calculations.

Depending on the design, glass parts may be made by:

After forming, edges are often ground or polished, and decorations or coatings may be applied. A dedicated overview like a glass lights manufacturing guide can help you visualise these steps.

Typical issues to monitor in glass components include:

On finished glass solar lights, also check:

Agreeing inspection standards and acceptable cosmetic grades for glass surfaces is essential, especially for premium ranges where end customers expect near-perfect appearance.

Glass requires more careful packaging and logistics planning than purely plastic products. Discuss with your supplier:

Proper packaging design reduces breakage during sea transport, warehousing and last-mile delivery, protecting your margins and brand reputation.

Glass offers distinct customisation opportunities:

When you plan a glass OEM project, decide which elements must be unique to your brand and which can reuse existing shapes, finishes or hardware to control cost.

Major cost and MOQ drivers for glass solar lights include:

Share your target ex-factory price ranges and expected volumes so your partner can propose realistic combinations of glass, decoration and packaging. Sometimes small design changes can reduce risk and cost without sacrificing visual impact.

Successful brands often create coordinated glass series instead of isolated items:

Planning series from the beginning allows your manufacturer to design tools, decorations and packaging with sharing in mind, making each new variant more efficient to launch.

To get targeted advice and realistic proposals, prepare at least:

Sharing this information early helps your supplier judge which glass types, processes and packaging solutions are appropriate and sustainable for your business.

Glass solar lights rely on both glass expertise and solar lighting know-how. When you evaluate suppliers, look for:

Manufacturers like Glowyard Lighting, who focus on solar garden lights and coordinate glass, metal or plastic parts through stable supply chains while controlling R&D, assembly and testing in-house, are typically better positioned to deliver consistent glass solar ranges than suppliers treating glass lights as occasional add-ons.

A typical OEM project for glass solar lights may follow these steps:

Understanding this flow helps you align internal timelines, coordinate packaging and marketing, and avoid last-minute surprises. If you prefer a structured start, you can also initiate projects through channels similar to an OEM or custom project request form so engineering, sales and quality teams are involved from the beginning.

Wanna Customize Your Solar Outdoor Lighting?

Glowyard Lighting Are here to help!

“Specializing in solar garden lights wholesale, with five production lines, committed to providing high-quality, cost-effective, and innovative lighting solutions for Europe, North America, Russia, and Australia markets.”

Scan By WeChat

Scan By WhatsApp

Fill Out The Form Below Or Reach Out To Us Directly

© 2020-2025 Glowyard Is A Trademark Of Soume Lighting Industry and Trade Co., Ltd. All Rights Reserved.

WhatsApp us

Plan Your Next Order Early – Don’t Miss the Peak Season!

- Free samples for qualified buyers

- OEM & ODM for solar garden lights

- Full pre-shipment QC and warranty support