How We Align Mold Design and Mass Production to Enable Fast Delivery and Low MOQs

In decorative solar lighting, tooling is often the real bottleneck. A new lantern, resin statue or plastic housing may look simple in a drawing, but if the handover between mold design and mass production is weak, factories lose weeks in debugging, scrap and unplanned downtime.

At Glowyard, many of our OEM/ODM projects involve new or shared tooling for plastic and resin housings. Over the years we’ve learned that managing the interface between tooling and production is one of the biggest levers behind our fast sampling, fast shipping and lower-than-industry MOQs. This article explains how we do it in practice.

For readers who want to see how this fits into our end‑to‑end capabilities, you can also refer to our outdoor lighting manufacturing overview.

When Tooling and Production Are Out of Sync, Everyone Loses

In many factories, the mold workshop and the production line behave like two separate worlds. The mold shop finishes the tooling, delivers it, and “the job is done”. Only when the injection machines start running do the real problems appear:

-

Debugging feels like gambling

New molds go onto the machine and technicians “try a bit of everything”: change temperature, pressure, cycle time and cooling again and again. Valuable production time is burned on parameter trial‑and‑error. -

Defects and rework quietly eat profit

Short shots, flash, sink marks, warpage and unstable dimensions lead to piles of scrap and rework. Material, labour and machine time are all wasted. -

Molds wear out early

Without a clear maintenance plan, even well‑made molds are over‑used, scratched or repaired in a rough way, shortening their life and increasing long‑term cost.

From the outside it may look like “production is busy”, but inside, a lot of margin is being silently destroyed by poor coordination.

Glowyard’s Principle: Delivering a “Stable Production System”, Not Just a Piece of Steel

Our core idea is simple:

The mold workshop should not just deliver a physical mold, but should deliver a stable, documented and maintainable production capability to the line.

This means engineering, tooling, production and quality teams work as one system. For OEM/ODM clients, the benefit is straightforward: faster ramp‑up, fewer surprises, and more predictable delivery, even for relatively low MOQs.

Step 1 – Design for Manufacturing with the Line in Mind

The first step happens before steel is cut.

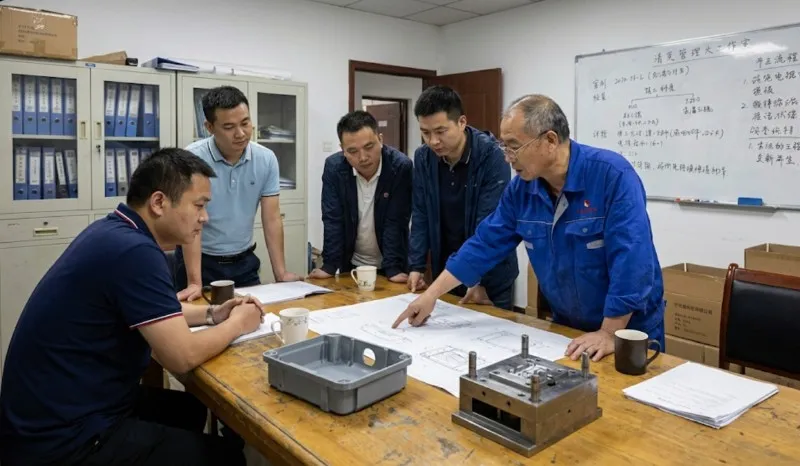

Cross‑functional DFM review

When we design or adapt a housing for a solar garden light, our mold engineers sit down with:

- Injection technicians from our in‑house or partner molding facilities

- Final assembly engineers (who understand how parts are clipped, glued or screwed)

- QC staff who will own dimensional and appearance checks

Together they review:

- Gate positions, parting lines and ejector layout

- Wall thickness and ribs for dimensional stability

- Draft angles, undercuts and potential sticking points

- Areas that are critical for sealing, optical performance or assembly

Design decisions tied to project goals

For example:

- If the buyer’s priority is fast lead time and low MOQ, we may recommend using or slightly modifying an existing shared mold.

- If the priority is a new signature shape or premium finish, we design a dedicated tool but still optimise for cycle time and maintenance access.

This front‑loaded alignment reduces the chance that a “beautiful” design becomes a headache on the machine.

Step 2 – Treat Mold Trials Like Experiments, Not Just a One‑Time Check

Many factories treat T0/T1 trials as a pass/fail event. We treat them as a structured experiment to find the golden recipe.

Systematic parameter mapping

During mold trials we do not only confirm “OK parts”. We map:

- Melt and mold temperatures

- Injection speed and holding pressure

- Cooling time and demoulding force

- Material batches and colour masterbatch ratios

Instead of relying on one technician’s “feeling”, we record combinations and the resulting part quality:

- Where does warpage disappear?

- At what parameters do we see the least sink marks?

- Which cycle time gives the best balance of quality and efficiency?

Output: a Golden Parameter Sheet

For each important mold, we output a parameter sheet that includes:

- Recommended machine type and screw size

- Verified process window (min–max) for key settings

- Known risk points and counter‑measures (e.g. “gate area prone to burn mark if injection speed too high”)

This sheet is handed over to production together with the physical mold. As a result, when the mold is moved across machines or shifts, technicians are not starting from zero every time.

For readers who want a more general view of how we standardise production steps, see our solar lights manufacturing guide.

Step 3 – Build a “Health File” for Each Critical Mold

We treat key molds as long‑term assets, not consumables.

Mold health records

For important housings or high‑volume SKUs, each mold has a simple digital health file that tracks:

- Shot count and material types used

- Past parameter adjustments and the reasons

- All repairs and component replacements (e.g. inserts, lifters, sliders)

- Quality incidents tied to that mold

Preventive maintenance instead of emergency fixes

Based on the health file and shot count, we schedule:

- Routine cleaning of vents, cooling channels and moving parts

- Early replacement of worn pins and bushings

- Periodic dimension checks on critical features

This approach significantly reduces unexpected breakdowns during peak seasons and extends tool life, which directly lowers amortised tooling cost per unit.

How This Supports Fast Delivery and Lower MOQs

All of the above might sound “internal”, but for buyers it translates into visible business value.

Faster ramp‑up from sample to mass production

Because the mold and production package are delivered together:

- New molds typically reach stable output in far fewer trial runs.

- Seasonal or repeat orders can restart quickly, even after a long gap.

This supports the lead times we commit to for sampling and mass production, as outlined in our broader outdoor lighting manufacturing overview.

Making low to medium MOQs financially workable

Glowyard’s business model is designed to support lower‑than‑industry MOQs, especially when:

- We adapt existing molds for new colours or minor appearance tweaks

- Multiple SKUs share a platform housing or internal structure

Because our molds start up faster and run more predictably, we can spread engineering and debugging cost over smaller batches without losing control of margin. Buyers who want to understand how this connects with order quantities and pricing can also refer to our purchasing guide for MOQs and ordering process.

A Typical Case: From “Always Debugging” to Stable Output

One OEM client came to us after struggling with another supplier on a plastic solar wall light:

- Each new batch required days of debugging before stable production.

- Visible defects and dimensional issues caused high scrap and rework.

- The factory often blamed “mold problems”, but the root cause was never fully traced.

When we took over:

- We re‑reviewed the mold design with our partner toolmaker and adjusted gating and venting.

- We ran structured trials and created a full golden‑parameter package.

- We set up a mold health file and basic preventive maintenance schedule at the molding partner.

In the next season:

- Time from “mold on machine” to stable mass production dropped by over 50%.

- Defects linked to the mold fell dramatically.

- The client was comfortable placing smaller repeat orders because they saw that switching the line on and off no longer came with a big debugging penalty.

What This Means for Your Projects

For brand owners and importers, good mold–production coordination is not a “nice to have”. It is directly tied to:

- How quickly your custom design can reach the market

- Whether low or stepped MOQs are realistic

- How much hidden cost sits behind every unit you import

When you discuss a new project with Glowyard, you are not only buying a set of solar garden lights. You are also buying into:

- A team that treats molds as production systems, not only steel blocks

- A documented, repeatable process from design to mass production

- A manufacturing setup that has been optimised for fast sampling, fast shipping and flexible order quantities

If you are considering a new design or want to stabilise an existing project, our OEM services for solar garden lights are structured around exactly this kind of cross‑department collaboration. You can share your drawings, problems and target timelines, and we will help you turn them into a realistic, production‑ready plan.

By tightening the connection between mold design and mass production, Glowyard turns what used to be “invisible internal friction” into visible advantages for clients: shorter lead times, more flexible MOQs and more predictable profit on every shipment.