“Specializing in solar garden lights wholesale, with five production lines, committed to providing high-quality, cost-effective, and innovative lighting solutions for Europe, North America, Russia, and Australia markets.”

We produce durable plastic components—including housings, diffusers, stakes and internal structural parts—using injection molding machines with precise temperature and pressure control. By selecting UV-resistant and outdoor-grade materials, we ensure each piece maintains strength, color stability and long-term performance under sun exposure.

Choosing the right plastic material is critical for ensuring durability, UV resistance, and long-term outdoor performance. Our factory uses certified outdoor-grade materials and UV-stable formulations to keep your solar lights performing reliably in all climates.

A stable and versatile material widely used in solar light housings.

Features:

Good dimensional stability

Smooth surface for painting

UV-resistant versions available for outdoor applications

Best For:

Light housings

Inner battery compartments

Structural components not directly exposed to sunlight

Lightweight and mildly flexible with better outdoor resistance than standard ABS.

Features:

Good chemical resistance

Affordable

Suitable for non-load-bearing components

Best For:

Light-diffusing covers

Decorative parts

Cost-efficient solar stake lights

The premium choice for outdoor solar lighting, especially for transparent or impact-resistant parts.

Features:

Excellent impact resistance

UV-stable grades can last 3–5 years outdoors

High transparency for optimal light diffusion

Best For:

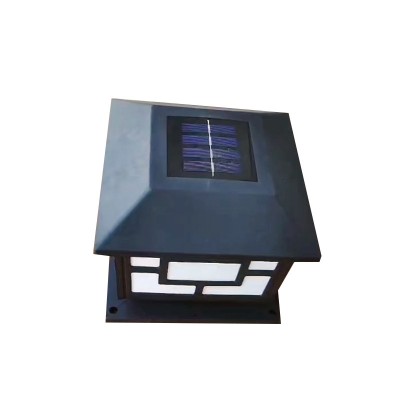

Lampshades

Impact-resistant housings

Premium garden & wall lights

A material known for its high clarity and elegant glass-like appearance.

Features:

Maximum transparency

Good surface hardness

Excellent visual effect

Best For:

Decorative light covers

Diffusion panels

High-end garden lanterns

Used in low-cost solar lights where impact performance is not critical.

Features:

Low cost

Acceptable clarity

Less suitable for long-term outdoor exposure

Best For:

Entry-level solar pathway lights

Promotional products

A strong engineering-grade solution for heavy-duty components.

Features:

High strength and wear resistance

Excellent durability

Available with glass-fiber reinforcement

Best For:

Structural connectors

Hinges, screws, rotating parts

Mechanical support components

Soft and flexible material used for sealing and waterproofing.

Features:

Great elasticity

Reliable outdoor sealing performance

Ideal for IP65+ designs

Best For:

Sealing rings

Soft buttons

Shock-absorbing components

When to choose plastic housings instead of metal, resin or glass, and how plastic helps you build high‑volume, price‑competitive solar garden light programs.

Plastic housings help you hit aggressive target prices for supermarket, DIY and e‑commerce sets while keeping the product visually attractive on shelf.

Injection‑molded parts with well‑designed tools allow consistent dimensions, fast cycles and stable quality across large orders and repeat seasons.

Plastic bodies reduce breakage risk versus glass and lower shipping costs for multi‑piece garden light sets or items aimed at families.

Plastic lenses, diffusers and light guides can be integrated into the housing to create patterns, glare control and soft light effects.

A step‑by‑step overview of how plastic solar lights move from material selection and tooling to molding, decoration, assembly and reliability testing.

Key plastic-related capabilities—from material selection and injection equipment to tooling and structural design—that support durable, lightweight solar garden lights.

Our injection molding services cover every stage, from design to delivery. We produce prototypes and large-scale parts with tight tolerances, certified quality, and quick lead times for global customers.

Explore representative plastic-based outdoor and solar lighting designs—such as lightweight garden stakes, pathway lights, string lights and tabletop decorations—that are manufactured using our plastic molding, assembly and quality control capabilities.

Common problems importers face with plastic solar lights, from yellowing and cracking to loose joints, water leakage and inconsistent quality between batches.

Low‑grade plastic and insufficient UV stabilization cause housings to yellow, crack or turn brittle after one or two seasons.

Over‑aggressive wall‑thickness reduction results in broken stakes, snapped hooks and customer complaints.

Inconsistent molding conditions lead to deformation, gaps, rattling parts and water ingress around joints and buttons.

Some suppliers cannot clearly tell you which resin grade, masterbatch or mold steel is used, making it hard to manage long‑term risk.

To understand how these issues appear across the whole production chain, you can review our outdoor lighting manufacturing overview.

Our engineering, material selection and process control methods for keeping plastic parts stable in outdoor conditions while still meeting your target price.

We match plastic grades (such as PP, ABS or PC) and UV‑stabilized masterbatches to your market climate, color requirements and lifetime expectations, instead of using generic indoor plastics.

Our R&D team designs ribs, snap‑fits, screw bosses and wall thickness with simulation and field experience, balancing strength, weight and cost.

Standardized injection or blow‑molding parameters, first‑article approval and regular dimensional checks reduce warping, flashing and assembly problems.

Plastic housings, gaskets and PCBs are co‑designed so that clips, screws and light windows all work together to maintain IP performance over time.

How our 4‑stage QC system, lab tests and packing verification reduce complaints and returns for plastic‑based solar garden lights.

Our factory holds BSCI, ISO 9001, and Sedex audits, and our products comply with CE, RoHS, FCC, UL, UKCA and more.

Key questions to ask and data to request from factories so you can balance cost, durability, tooling investment and long‑term program stability.

In your RFQ, define whether you need galvanized steel, aluminum or stainless, the minimum thickness, and expected outdoor lifetime (e.g., 48/96‑hour salt‑spray, coastal vs inland).

Approve a powder‑coat chip and a finished metal part as “golden sample” with agreed RAL (or near‑equivalent), gloss level and texture. Require any formula change to be re‑approved.

Metal solar lights are heavier and more rigid than plastic or resin. Confirm carton drop‑test requirements, pallet stacking limits and how sets are packed to avoid transport damage and extra freight costs.

New molds, special coatings or complex welding structures require larger MOQ and longer lead time. Reserve these for core SKUs, and use simpler modifications for test orders or seasonal runs.

For more practical details on MOQ, lead times and ordering flow, refer to our purchasing guide for solar garden lights.

Practical guides, FAQs and insights on plastic material selection, UV stability, structure design, waterproofing and production best practices to help buyers design and source better plastic-based solar outdoor lights.

Plastic solar lights are the backbone of many outdoor lighting assortments. Compared with metal, resin or glass, plastic housings are typically lighter, more cost-effective and easier to scale for high-volume retail programs. When designed and manufactured correctly, they can still deliver reliable outdoor performance and attractive appearance for multiple seasons.

This buyer’s guide walks you through the main decisions you should make before sourcing or developing plastic solar lights. It is written for importers, wholesalers, retailers and brand owners who want to balance cost, durability and design across large consumer ranges.

Each housing material has its own strengths. Plastic solar lights usually fit best in the following roles:

Metal and glass often carry premium or architectural positioning, while resin supports detailed figurines and storytelling. Plastic fills the wide space between them, giving you flexibility on cost, weight and styling. When you plan your category, decide clearly which parts of your range will use plastic and where you will upgrade to other materials.

Plastic solar lights are widely used in:

Understanding these use cases helps you decide:

Several thermoplastics are frequently used in outdoor solar lights. Each has different properties for impact strength, UV stability, appearance and cost:

Discuss with your manufacturer which materials they propose for each component and how those materials perform in your target climates. A dedicated overview of plastic lights manufacturing, similar to a plastic lights manufacturing guide, can make these options clearer for your internal team.

With plastic, structural design is just as important as material choice. Poor structure can cause:

To avoid these issues, clarify early:

Good engineers will adjust draft angles, radii and wall transitions to balance appearance, strength and mouldability. Ask your supplier to explain any recommended changes to your initial design so you can understand the trade-offs.

Plastic solar lights are often handled more roughly than metal or glass products, especially in retail environments. Design choices that improve performance include:

Surface finish also matters. Textures can hide small scratches and flow marks, whereas high-gloss surfaces highlight any defects. Decide where premium high-gloss is necessary and where fine matte textures or hairline patterns are more practical for long-term appearance.

UV radiation is one of the biggest challenges for outdoor plastics. Without proper stabilisation, problems can include:

To manage these risks, you should ask:

Align your expectations with your target markets: strong sun and high temperature regions require more robust solutions than mild climates, and this may influence both material selection and cost.

Plastic allows you to combine structural and optical functions in a single part. When planning your designs, think carefully about:

Provide RAL or Pantone references where possible, and agree on sample standards that define acceptable variation. For lenses and diffusers, ask for trial shots or sample parts with LEDs lit at night to confirm the light effect matches your expectations.

Beyond basic IP tests for water and dust ingress, outdoor plastic parts may be evaluated with:

Ask your supplier which of these tests are part of their standard quality system and which can be added for specific projects. A general quality overview, similar to a quality and testing page, can give you a clear view of typical practices.

A successful plastic project starts with clear design data and a realistic view of tooling:

Based on this, the factory will design and build injection moulds (or other tooling where relevant). Good suppliers will discuss:

Injection moulding quality has a major influence on the final look and fit of your plastic solar lights. Common issues include:

During sampling, review parts carefully under good lighting and assemble them with the real solar components. Discuss acceptable cosmetic grades for each surface and agree on clear inspection criteria. Manufacturers with strong process control will be able to explain how they tune moulding parameters and maintain consistency between batches.

Plastic housings, lenses and internal holders must work together with electronics and batteries. When you review assembly, look at:

Final inspection should combine appearance checks (for example scratches, flow marks, colour consistency) with functional and waterproof testing before packing.

With plastic, you often combine housing, lens and decorative elements in one system. Design decisions that influence the user experience include:

Request night-time photos or short videos of samples in realistic setups so you can judge the light effect before committing to mass production.

Plastic itself does not rust, but sealing and heat management still require attention:

Agree on target IP ratings for different model types and ask how the design and assembly process achieve those ratings consistently in production, not only in lab samples.

Plastic is well-suited for scalable customisation:

Work with your supplier to identify which customisations can reuse existing tools and which require new tooling. This helps you create differentiated designs without excessive investment.

For plastic solar lights, cost and MOQ are strongly influenced by:

Discuss openly with your supplier:

This will help them propose realistic MOQs and cost structures. General purchasing guidelines, similar to a purchasing tips page, can support these internal decisions.

Instead of many unrelated single items, you can gain more value from coherent plastic series that share design language and components:

Plan your series early so your manufacturer can design tools and components with sharing in mind. This reduces inventory complexity and simplifies future updates or seasonal variations.

To receive meaningful proposals rather than generic quotations, prepare at least:

Even if some details may change later, sharing your assumptions will help the supplier recommend suitable material combinations, structures and cost levels from the beginning.

Plastic solar lights combine plastic processing with electronics and outdoor design. When screening suppliers, look for:

Glowyard Lighting, for example, focuses on solar garden lights and works with dedicated plastic tooling and moulding partners while controlling core functions such as R&D, electronics, assembly and testing in-house. This combination of specialisation, process control and audited quality systems is what you should look for when choosing long-term plastic solar light partners.

A structured OEM flow for plastic solar lights often includes:

Understanding this process helps you set realistic development timelines, coordinate internal approvals and plan launches. If you prefer a structured project start, you can also share your brief through channels similar to a OEM solutions or custom project form so the engineering and sales teams can respond in a coordinated way.

Send Us Inquiry

Wanna Customize Your Solar Outdoor Lighting?

Glowyard Lighting Are here to help!

“Specializing in solar garden lights wholesale, with five production lines, committed to providing high-quality, cost-effective, and innovative lighting solutions for Europe, North America, Russia, and Australia markets.”

Scan By WeChat

Scan By WhatsApp

Fill Out The Form Below Or Reach Out To Us Directly

© 2020-2025 Glowyard Is A Trademark Of Soume Lighting Industry and Trade Co., Ltd. All Rights Reserved.

WhatsApp us

Plan Your Next Order Early – Don’t Miss the Peak Season!

- Free samples for qualified buyers

- OEM & ODM for solar garden lights

- Full pre-shipment QC and warranty support