How to Improve the Durability of Plastic in Solar Garden Lights Under Outdoor Sun Exposure?

When you choose solar garden lights, you’re making an investment in both functionality and aesthetics for your outdoor spaces. However, there’s one challenge that often goes unnoticed: plastic degradation due to prolonged exposure to UV radiation. This degradation can lead to fading, cracking, and even failure of the light.

If you’re a distributor or procurement officer, understanding how to protect the plastics in your solar lights is critical to offering long-lasting products to your customers. This article will explore how to improve the durability of plastic in solar garden lights under outdoor sun exposure and provide practical solutions to ensure high-quality, long-lasting products.

As a manufacturer with a focus on high-quality solar lighting solutions, Glowyard Lighting understands the challenges posed by outdoor conditions. We are committed to providing our distribution partners with products that are not only functional but also durable enough to withstand the test of time. This article offers insights on how we can help you offer products that stand out in the market for their longevity and performance.

UV Resistance in Plastics

Understanding UV Resistance and Plastic Degradation Mechanism

How Does UV Radiation Affect Plastic Materials?

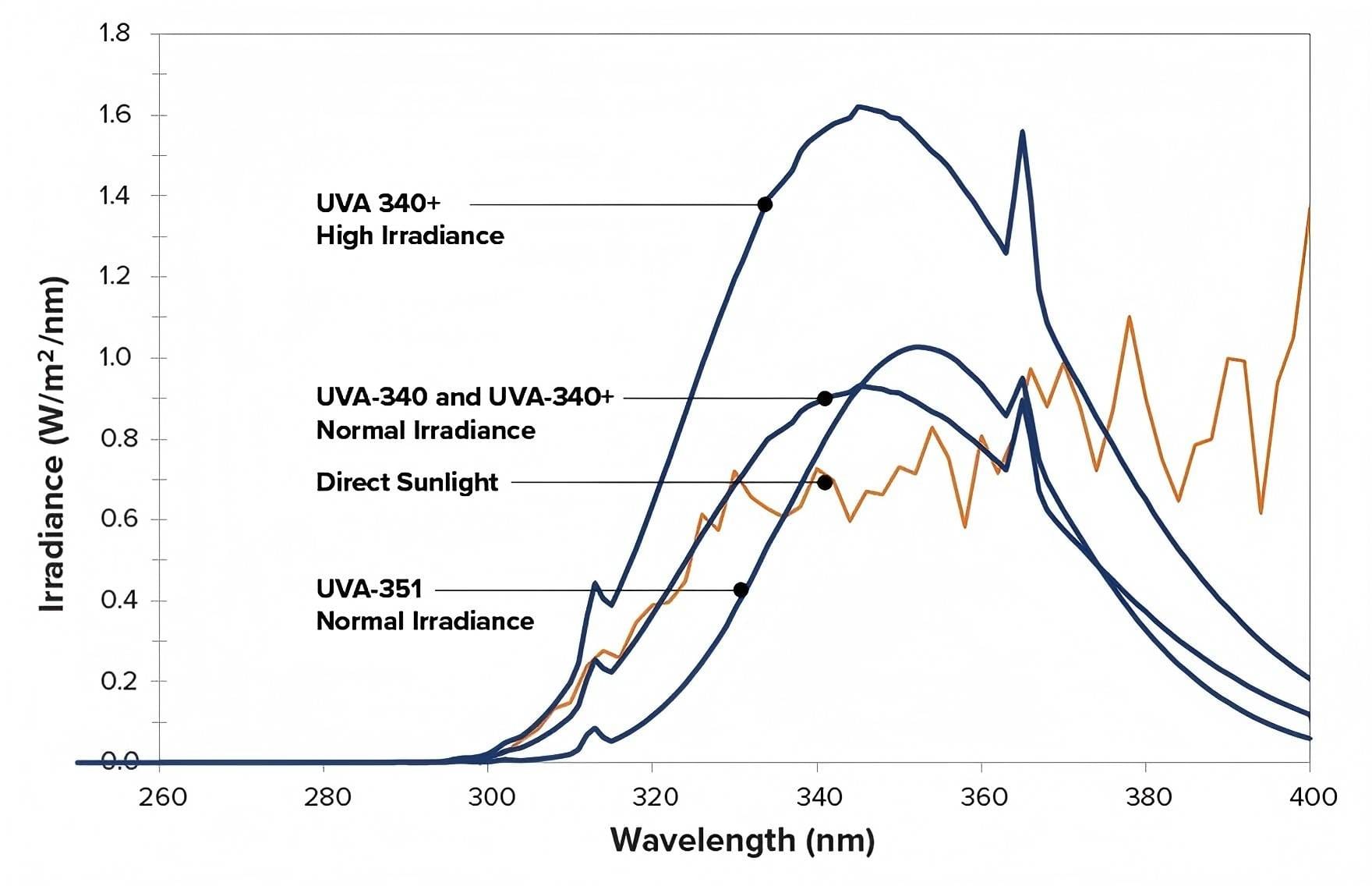

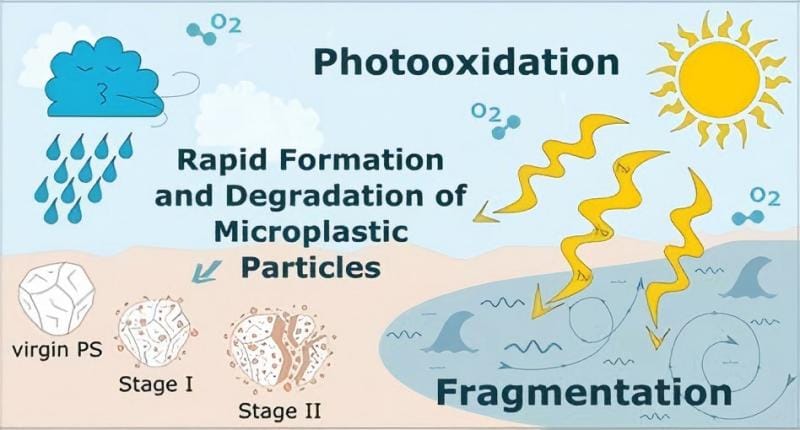

Plastic degradation under UV radiation is a major concern for solar garden lights. The sun emits ultraviolet (UV) rays, which break down the chemical bonds in plastic over time. This process is known as photodegradation, and it leads to various negative effects on plastics, such as discoloration, cracking, and brittleness. Understanding the underlying mechanisms of this degradation is the first step toward improving the durability of plastic used in solar garden lights.

When plastic is exposed to UV radiation, the energy from the UV rays disrupts the molecular structure of the polymer chains. This results in the formation of free radicals, which further react with oxygen to cause oxidation. Oxidation weakens the plastic, leading to the loss of flexibility and strength.

Plastic Degradation Process

How Does UV Exposure Affect Solar Garden Lights?

For solar garden lights, this degradation process is particularly problematic. As the plastic becomes weaker, it may crack, leading to mechanical failure of the product. Additionally, the color may fade, reducing the aesthetic appeal of the lights. In the worst-case scenario, the plastic may become so brittle that it breaks apart entirely. All of these effects lead to customer dissatisfaction and increased after-sales service requirements for distributors.

At Glowyard Lighting, we address these challenges by selecting materials that resist UV degradation, ensuring that the lights remain functional and visually appealing for longer periods.

Methods to Enhance Plastic Weatherability: UV-Resistant Additives and Coatings

How Can Additives Improve Plastic Durability?

One of the most effective ways to improve the weatherability of plastics used in solar garden lights is by incorporating UV-resistant additives. These additives are chemical compounds that can be added during the production of plastic materials. Their role is to absorb harmful UV radiation and prevent it from breaking down the polymer chains.

Some of the most common UV-resistant additives include:

- Benzotriazoles: These are powerful UV absorbers that prevent the degradation of plastic by absorbing UV light and converting it into harmless heat.

- Hindered Amine Light Stabilizers (HALS): These compounds work by scavenging free radicals, preventing the chain reactions that lead to plastic degradation.

By incorporating these additives, the plastic used in solar garden lights becomes more resistant to UV damage. This allows the lights to maintain their strength and color, even after prolonged exposure to sunlight.

UV Absorber UV-328 – Anti-aging, Anti-yellowing, UV Protection and Light Stabilizer for Plastics

Protective Coatings: A Key Layer of Defense

In addition to UV-resistant additives, another important solution is the application of protective coatings. These coatings act as a physical barrier between the UV rays and the plastic, preventing the radiation from reaching the material beneath. Coatings can be applied directly to the surface of the plastic either during manufacturing or post-production.

There are different types of UV-blocking coatings:

- Clear Coatings: These coatings allow the natural appearance of the plastic to remain while protecting it from UV damage.

- Tinted Coatings: In some cases, tinted coatings may be applied to further enhance UV resistance while providing additional aesthetic value.

These coatings not only prevent UV degradation but also offer additional benefits such as water resistance, which is crucial for outdoor products exposed to various weather conditions.

Testing and Evaluation: Assessing Plastic Performance in Outdoor Environments

How Do Manufacturers Test UV Resistance and Durability?

To ensure that solar garden lights perform well under harsh outdoor conditions, it’s not enough to rely on design and materials alone. Comprehensive testing is essential to validate how the plastic components respond to UV radiation, temperature changes, and humidity. At Glowyard Lighting, we use a combination of accelerated aging tests and real-world testing to make sure our products can withstand extended outdoor use.

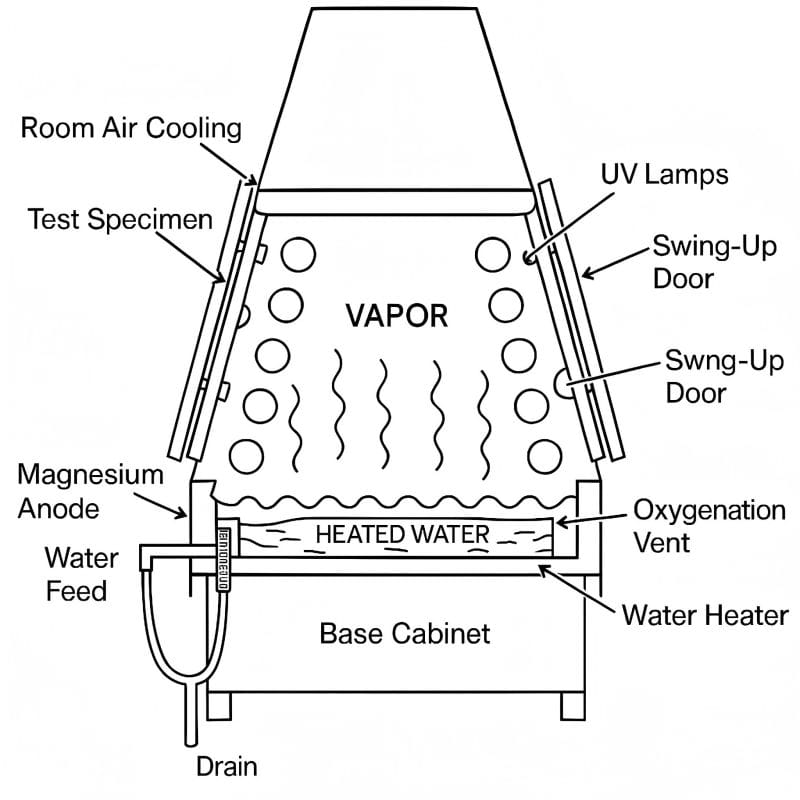

One of the most important tools we use is the UV aging test chamber, also known as a UV weathering test machine. This equipment simulates years of sunlight exposure within a controlled environment, allowing us to predict how plastic materials will perform over time.

UV Test Chamber

What Is a UV Aging Test Chamber?

A UV aging test chamber is a specialized piece of equipment designed to mimic natural weathering conditions, particularly ultraviolet (UV) radiation from the sun. It exposes plastic samples to controlled cycles of UV light, high temperature, and humidity to accelerate the aging process. In a short period—typically a few hundred hours—it can replicate the effects of several months or even years of outdoor exposure.

Diagram of a UV weathering test chamber

Key Features of the Equipment:

| Feature | Description |

|---|---|

| UV Light Source | Uses UV fluorescent lamps (UVA or UVB) to simulate solar radiation |

| Temperature Control | Maintains stable high temperatures (40–70°C) to simulate heat exposure |

| Humidity System | Simulates condensation, dew, and moisture to mimic early morning conditions |

| Time-Cycle Programming | Allows alternating cycles of UV light and moisture |

| Surface Evaluation | Enables visual inspection of color fading, cracking, and brittleness |

By using this machine, we can observe:

- Color retention: Does the plastic maintain its original color?

- Structural integrity: Does the material crack or become brittle?

- Surface quality: Are there signs of chalking, discoloration, or deformation?

The Importance of Real-World Testing

Beyond laboratory tests, we also conduct real-world environmental testing. This involves placing the plastic materials in various outdoor environments to assess how they respond to different weather conditions. This ensures that the materials we use in our solar garden lights can withstand a wide range of climates, whether it’s hot, humid, or dry.

Our comprehensive testing process guarantees that the products you receive are of the highest quality and will meet the durability standards required by your customers.

Conclusion: Delivering High-Quality Solar Garden Lights for Long-Term Satisfaction

By understanding how UV radiation affects plastics and implementing solutions like UV-resistant additives, coatings, and rigorous testing, we can significantly improve the durability of solar garden lights. These enhancements not only increase the lifespan of the lights but also reduce after-sales service requirements, offering distributors like you a high-quality product that your customers will appreciate.

Are you looking for a Solar garden lights supplier?

Glowyard new solar garden light product launch with creative outdoor designs

At Glowyard Lighting, we are committed to delivering solar garden lights that are built to last. Our products feature UV-resistant materials, high-quality additives, and protective coatings, all backed by extensive testing to ensure they perform well under outdoor sun exposure. As a trusted B2B manufacturer, we work closely with distributors to provide high-quality products that minimize after-sales issues and maximize customer satisfaction.

For distributors seeking reliable solar lighting solutions, Glowyard Lighting offers cost-effective, durable [decorative solar garden lights](https://glowyard.com/decorative-outdoor-solar-garden-lights/ “decorative solar garden lights”) that meet the highest industry standards. Reach out to us today for more information on how we can help you grow your business with long-lasting solar garden lights.

Visit our website: [www.glowyard.com](http://www.glowyard.com) or contact us at info@glowyard.com for wholesale inquiries and product information.